Cofferdams

advertisement

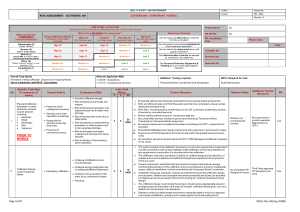

Cofferdam 1 2 During the construction of bridges , dams or any other structure where the foundation part of the structure is most likely to lie underwater, we have to opt for underwater construction Construction in water poses many difficulties especially in the places where there the depth is considerable. During underwater construction our main objective is to create dry and water free environment for working in such a manner that the structural stability of the structure is not compromised. 3 UNDERWAT ER CONSTRUC TION Constructi on technique s Methods of Placing of concrete Caissons Cofferda ms Tremie method Pump method Toggle bags Bag works 4 Caissons: Watertight retaining structure . Permanent in nature. Used to work on foundation of bridge pier, construction of concrete dam or for the repair of ships. Constructed in such a manner so that the water can be pumped out. Keeps working environment dry. Working inside a caisson 5 TYPES OF CAISSONS 6 Control post Open caisson grab Ground water level Circumferential gap shoe pontoon Ballast water Box caisson 7 PNEUMATIC CAISSON •Large inverted box on which pier is built. •Compressed air is used to keep the water and mud out. •Used to work on riverbed or quicksand's. 8 Suction caisson • More suitable for off shore construction. • Upturned bucket embedded in marine sediment. • Embedment achieved by pushing or by creating negative pressure. 9 ADVANTAGES OF CAISSONS Economic. Slightly less noise and reduced vibrations. Easily adaptable to varying site conditions. High axial and lateral loading capacity. Minimal handling equipment is required for placement of reinforcing cage. Placement is sometimes possible in types of soil that a driven pile could not penetrate 10 Dangers encountered: Caisson disease is so named since it appeared in construction workers when they left the compressed atmosphere of the caisson and rapidly re entered normal (decompressed) atmospheric conditions. Construction of the Brooklyn Bridge, which was built with the help of caissons, resulted in numerous workers being either killed or permanently injured by caisson disease during its construction, including the designer's son and Chief Engineer of the project. 11 Cofferdams: Temporary structure Built within or in pairs across a body of water Allows the enclosed space to be pumped out, creating a dry work environment . Enclosed coffers are commonly used for construction and repair of oil platforms, bridge piers and other support structures built within or over water. A cofferdam involves the interaction of the structure, soil, and water. The loads imposed include the hydrostatic forces of the water, as well as the dynamic forces due to currents and waves. Used for shallow constructions having depth less than 10m. Working inside a cofferdam 12 DEPT. OF CIVIL ENGINEERING GCET JAMMU 13 Components of cofferdam: Sheet piling Sheet piling is a manufactured construction product with a mechanical connection “interlock” at both ends of the section. These mechanical connections interlock with one another to form a continuous wall of sheeting. Brace piling Concrete seal Sheet piles Bracing frame COFFERDAM CONSTRUCTION SEQUENCE: 14 1. Pre-dredge to remove soil or soft sediments and level the area of the cofferdam 2. Drive temporary support piles. 3. Temporarily erect bracing frame on the support piles 4. Set steel sheet piles. 5. Drive sheet piles to grade. 6. Block between bracing frame and sheets, and provide ties for sheet piles at the top as necessary 7. Excavate inside the grade or slightly below grade, while leaving the cofferdam full of water 8. Drive bearing 9. Place rock fill as a levelling and support course. 10. Place Tremie concrete seal . 15 ADVANTAGES OF COFFERDAM: Allow excavation and construction of structures in otherwise poor environment. Provides safe environment to work. Contractors typically have design responsibility. Steel sheet piles are easily installed and removed. Materials can typically be reused on other projects. 16 CONCLUSION: Cofferdams are temporary structures and used in cases where the plan area of foundation is very large, depth of water is less and for the soft soils, where soils allow easy driving of sheet piles. Caissons are permanent structures and becomes economical in cases where the plan area of foundation is small, large depth of water and for loose soils. Suction caisson anchors are gaining considerable acceptance in the offshore industry.