Caisson Design: Types, Considerations, and Construction Methods

advertisement

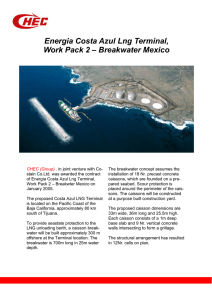

Design of Caissons ChatGPT Caissons are large watertight structures used in construction, particularly for underwater foundations, bridge piers, and dock structures. They provide a dry working environment underwater and are essential for projects involving deep foundations in rivers, lakes, or marine environments. The design of caissons involves careful consideration of structural integrity, buoyancy, stability, and construction method. There are several types of caissons, each suited to specific conditions and construction needs. Types of Caissons 1. Open Caissons Description: A box-like structure with an open bottom and closed top, often used in shallow water. Construction: Typically constructed onshore and then floated to the site, where they are sunk into place. Applications: Bridge piers, docks, and similar structures where the caisson can be lowered into position. 2. Box Caissons Description: Similar to open caissons but with a closed bottom, creating a watertight box. Construction: Prefabricated onshore and floated to the site, then sunk by filling with water or ballast. Applications: Used in conditions where it is necessary to have a dry working area at the bottom. 3. Pneumatic Caissons Description: A box or cylinder with an airtight chamber where work can be done under air pressure. Construction: Workers enter the chamber through airlocks, and compressed air prevents water from entering. Applications: Deep foundations where the caisson must penetrate into the bedrock or through unstable soils. 4. Floating Caissons Description: Large hollow structures that are floated into position and then sunk by adding weight. Construction: Built onshore and towed to the site, where they are flooded and sunk. Applications: Large marine projects such as quay walls, breakwaters, and other large-scale water structures. Design Considerations 1. Structural Integrity Materials: Typically constructed from reinforced concrete or steel, chosen for durability and strength. Reinforcement: Proper reinforcement is necessary to withstand the loads and stresses during sinking and operational phases. Load Bearing: Designed to carry the loads from the superstructure and distribute them to the foundation soil or bedrock. 2. Buoyancy and Stability Buoyancy Control: The caisson must be buoyant enough to float during transportation but can be ballasted to sink into place. Stability During Sinking: Measures to prevent tilting or rolling during the sinking process include using guide piles or anchor cables. Permanent Stability: Once in place, the caisson must remain stable under operational loads and environmental forces such as currents and waves. 3. Foundation Preparation Site Investigation: Thorough geotechnical investigation to understand soil conditions, bearing capacity, and any potential hazards. Preparation: Depending on soil conditions, preparation may include dredging, leveling, or even the use of temporary guide piles to ensure correct positioning. 4. Construction Method Onshore Construction: Prefabrication in dry docks or on slipways allows for controlled construction environments and quality control. Transportation: Careful planning of the transportation route and method, whether floating or towing, to the installation site. Sinking: Controlled sinking by filling compartments with water or ballast, ensuring an even descent to avoid tilting. Sealing: Sealing the base of the caisson to prevent water ingress, often using grouting or other sealing techniques once the caisson is in place. 5. Environmental and Safety Considerations Environmental Impact: Minimizing impact on the aquatic environment, including measures to protect water quality and marine life. Worker Safety: Ensuring safety protocols for workers, particularly in pneumatic caissons where air pressure is involved. Example Design Process for a Box Caisson 1. Initial Design and Planning Define the requirements based on the project scope, including dimensions, loadbearing capacity, and site conditions. Perform a geotechnical survey to understand soil characteristics and water depth. 2. Structural Design Calculate loads and stresses, including self-weight, live loads from the superstructure, and environmental loads (wave, current, and seismic). Design the caisson walls and base with appropriate reinforcement to handle these loads. Ensure watertight integrity, using high-quality concrete mix and waterproofing measures. 3. Construction Preparation Prefabricate the caisson in a dry dock with careful attention to alignment and dimensions. Install necessary fittings for ballast tanks, guide piles, and other operational features. 4. Transportation and Sinking Float the caisson to the site using tugboats or other suitable methods. Gradually fill the caisson with water or ballast to sink it into position, monitoring for stability and alignment. Once in place, seal the base using grout or similar materials to create a watertight structure. 5. Final Adjustments and Integration Perform any necessary leveling or adjustments to ensure the caisson is properly seated on the foundation. Integrate the caisson with the superstructure, ensuring all joints and connections are secure. Conclusion The design of caissons involves a detailed and multifaceted approach, considering structural integrity, buoyancy, stability, foundation preparation, and construction methods. Each type of caisson is suited to specific conditions and project requirements, and careful planning and execution are essential to ensure the success and longevity of the structure. By addressing these key considerations, engineers can create effective and durable caisson foundations for a wide range of marine and underwater construction projects.