Chapter 4: Measuring Sitework, Excavation, and Piling

Chapter 4

Measuring Sitework, Excavation, and Piling

Objectives

• Upon completion of this chapter, you will be able to:

– Determine the likely soil conditions at a site by studying a soils report

– Explain the use of swell factor and compaction factor when calculating volumes of excavation and backfill

Objectives (cont’d.)

– Define bank measure and explain how it applies to sitework takeoffs

– Describe and use the “grid method” of calculating cut and fill volumes

– Describe and use the “section method” of calculating cut and fill volumes

– Explain how piling work is measured in a takeoff

Objectives (cont’d.)

– Explain how trenches and basements are measured in a takeoff

– Complete a manual takeoff of sitework

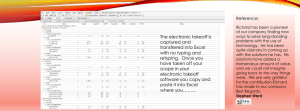

– Complete a computer takeoff of sitework using Excel spreadsheets and MC 2 ICE software

Generally

• Measuring sitework and excavation work

– Different from measuring most other work

• Current site condition may not be provided

• Dimensions and shape of excavations may not be disclosed

– Estimators must assess requirements before measuring site work

Soils Report

• Provides subsurface condition information

– Usually not a bid document

– Includes data for foundation system design

• Comments on sample soils report

– Topsoil, moisture content, soil compaction, slope ratio, drainage, etc.

Bank Measure, Swell, and

Compaction Factors

• Extracted soil

– Less dense and will occupy more space

• Compaction factor

– Difference between hole volume and fill material volume

• Bank measure

– Obtained using hole dimensions

Excavation Safety Considerations

• Potential danger to workers

– Cave-ins

• OSHA’s Construction Safety and Health

Regulations

– Requires shoring systems or cutting back sides to a safe angle

• Strongly enforced

Use of Digitizers

• Electronic devices

– Enables user to take measurements from drawings

• Input directly into computer program

• Digitizer types

– Sonic

– Tablet

On-Screen Takeoff

• Eliminates need for paper-based printouts

– Number of formats

– Cost savings

– Speed

– Convenience

• Plans still have to be drawn to scale

Measuring Notes —Excavation and Backfill

• Include:

– Measure in cubic yards or cubic meters

“bank measure”

– Classify and measure separately

• Excavations

• Materials

• Hand excavation

• Disposal of surplus soil

Calculation of Cut and Fill

Using the “Grid Method”

• Requires a site survey

– Showing elevation of existing grade

• Each intersection point on the grid

• Plotted at each intersection point

• Depth of cut can be obtained at each point

– Refer to Figures 4.1 and 4.2

• Accuracy depends on grid spacing

Calculation of Cut and Fill

Using the Section Method”

• Mostly used with long, relatively narrow areas of cut and fill

– Road and railroad construction

• Results quality depends on accuracy of plotting

– Refer to Figure 4.3

Trench Excavations

• Formula for trench volume:

– Trench Volume = Length of Trench Centerline

× Average Width of Trench × Average

Depth of Trench

– Refer to Figure 4.4

• Sides of trenches often cut-back due to:

– Safety reasons

– Soil will not stand vertically

Trench Backfill

• Volume of backfill for a trench

– Generally equal to volume of excavation minus volume of what is to be contained

– Surplus occurs when volume of excavation exceeds amount required for backfill

• Item for disposal of surplus material is required

Greater Accuracy

• Formula used to calculate volume of excavation:

– Usually sufficient

– Some situations require more accuracy

• Example: pit and basement excavations

Measuring Notes —Piling

• Often subcontracted to specialized companies

• Typical general contractor items:

– Layout of piles

– Cutting off tops of piles

– Removing excavated material

Bearing Piles

• Generally:

– Measure in linear feet or meters

– Include a separate lump-sum item for equipment

– Piles that are measures separately

– Measurement may be subdivided

– Enumerate splicing and lengthening of piles

Bearing Piles (cont’d.)

• Additional considerations:

– Classification of bearing piles

– Timber piles

– Steel piles

– Precast concrete piles

– Poured-in-place concrete piles

Sheet Piling

• Generally:

– Described and measured in square feet or square meters

– Separately measure piles

– Measurement may be subdivided

– Measure withdrawing of piles

– Cutting off of sheet piling: measured in linear feet or meters

Sheet Piling (cont’d.)

– Splices: described and measured by number

– Timber sheet piling, concrete sheet piling, and steel sheet piling: measured according to foregoing principles

– Extraction of piles: measured separately

Additional Examples

• Drawings

– Refer to Figures 4.11 and 4.12

• Sitework takeoff

– Example 1—The House Project

• Takeoff Shown as Figure 4.6a

– Example 2—The Office/Warehouse Project

• Takeoff Shown in Figure 4.14a

– Sitework Takeoff Using ICE Software

Summary

• The estimator has to make an assessment of sitework requirements

– Based on plans and specifications

• Site visit

• Soils report

– Efficiency can be increased using a digitizer

– Sitework takeoffs can be done manually or via computer