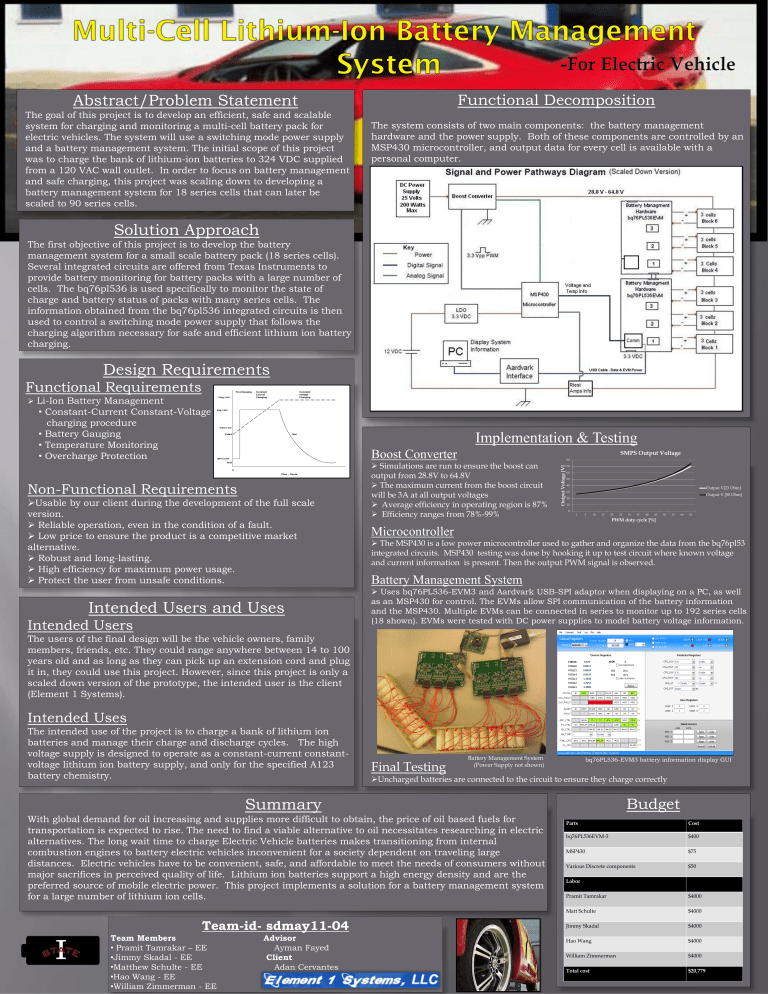

Multi-Cell Lithium-Ion Battery Management System

Abstract/Problem Statement

The goal of this project is to develop an efficient, safe and scalable system for charging and monitoring a multi-cell battery pack for electric vehicles. The system will use a switching mode power supply and a battery management system. The initial scope of this project was to charge the bank of lithium-ion batteries to 324 VDC supplied from a 120 VAC wall outlet. In order to focus on battery management and safe charging, this project was scaling down to developing a battery management system for 18 series cells that can later be scaled to 90 series cells.

Functional Decomposition

The system consists of two main components: the battery management hardware and the power supply. Both of these components are controlled by an

MSP430 microcontroller, and output data for every cell is available with a personal computer.

Solution Approach

The first objective of this project is to develop the battery management system for a small scale battery pack (18 series cells).

Several integrated circuits are offered from Texas Instruments to provide battery monitoring for battery packs with a large number of cells. The bq76pl536 is used specifically to monitor the state of charge and battery status of packs with many series cells. The information obtained from the bq76pl536 integrated circuits is then used to control a switching mode power supply that follows the charging algorithm necessary for safe and efficient lithium ion battery charging.

Design Requirements

Functional Requirements

Li-Ion Battery Management

• Constant-Current Constant-Voltage charging procedure

• Battery Gauging

• Temperature Monitoring

• Overcharge Protection

Non-Functional Requirements

Usable by our client during the development of the full scale version.

Reliable operation, even in the condition of a fault.

Low price to ensure the product is a competitive market alternative.

Robust and long-lasting.

High efficiency for maximum power usage.

Protect the user from unsafe conditions.

Implementation & Testing

SMPS Output Voltage

Boost Converter

Simulations are run to ensure the boost can output from 28.8V to 64.8V

The maximum current from the boost circuit will be 3A at all output voltages

Average efficiency in operating region is 87%

Efficiency ranges from 78%-99%

40

30

20

10

0

80

70

60

50

1 5 10 15 20 25 30 35 40

PWM duty cycle [%]

45 50 55 60 65

Output V[23 Ohm]

Output V [50 Ohm]

Microcontroller

The MSP430 is a low power microcontroller used to gather and organize the data from the bq76pl53 integrated circuits. MSP430 testing was done by hooking it up to test circuit where known voltage and current information is present. Then the output PWM signal is observed.

Battery Management System

Uses bq76PL536-EVM3 and Aardvark USB-SPI adaptor when displaying on a PC, as well as an MSP430 for control. The EVMs allow SPI communication of the battery information and the MSP430. Multiple EVMs can be connected in series to monitor up to 192 series cells

(18 shown). EVMs were tested with DC power supplies to model battery voltage information.

Intended Users and Uses

Intended Users

The users of the final design will be the vehicle owners, family members, friends, etc. They could range anywhere between 14 to 100 years old and as long as they can pick up an extension cord and plug it in, they could use this project. However, since this project is only a scaled down version of the prototype, the intended user is the client

(Element 1 Systems).

Intended Uses

The intended use of the project is to charge a bank of lithium ion batteries and manage their charge and discharge cycles. The high voltage supply is designed to operate as a constant-current constantvoltage lithium ion battery supply, and only for the specified A123 battery chemistry.

Summary

Team Members

• Pramit Tamrakar – EE

• Jimmy Skadal - EE

• Matthew Schulte - EE

• Hao Wang - EE

• William Zimmerman - EE

Team-id- sdmay11-04

Advisor

Ayman Fayed

Client

Adan Cervantes

Battery Management System

(Power Supply not shown) bq76PL536-EVM3 battery information display GUI

Final Testing

Uncharged batteries are connected to the circuit to ensure they charge correctly

With global demand for oil increasing and supplies more difficult to obtain, the price of oil based fuels for transportation is expected to rise. The need to find a viable alternative to oil necessitates researching in electric alternatives. The long wait time to charge Electric Vehicle batteries makes transitioning from internal combustion engines to battery electric vehicles inconvenient for a society dependent on traveling large distances. Electric vehicles have to be convenient, safe, and affordable to meet the needs of consumers without major sacrifices in perceived quality of life. Lithium ion batteries support a high energy density and are the preferred source of mobile electric power. This project implements a solution for a battery management system for a large number of lithium ion cells.

Budget

Parts bq76PL536EVM-3

MSP430

Various Discrete components

Cost

$400

$75

$50

Labor

Pramit Tamrakar

Matt Schulte

Jimmy Skadal

Hao Wang

William Zimmerman

Total cost

$4000

$4000

$4000

$4000

$4000

$20,779