Laporan Bergambar KTP I-gt/13 (UPM-11)

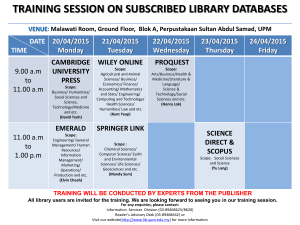

advertisement

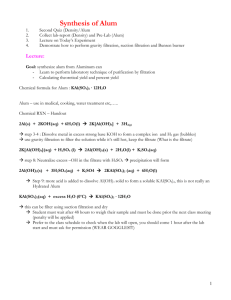

GREEN TECHNOLOGY IN WATER SUPPLY – USE OF NONCHEMICAL NATURAL POLYMER TO TREAT RIVER WATER PROF DR AZNI IDRIS UNIVERSITI PUTRA MALAYSIA Industrial Collaborator: PAKAR MANAGEMENT TECHNOLOGY (M) SDN BHD 1 TABLE OF CONTENT Introduction and background Project description Project activities Impact to industry/community Impact to graduate training Others – MPSJ Green town – future plans 2 Introduction and Background INTRODUCTION In Malaysia, river water - the main source of water supply Drinking water - treated by the water treatment plant. Aluminum Sulfate (Alum) - used in water treatment widely. Negative Impact of Alum - Parkinson and Alzheimer’s disease and produce hazardous toxics waste due to Aluminum sludge Need for alternative way to treat water 3 Introduction and Background Chemicals used to Produce Drinking Water Bauxite mining is polluting Bauxite ore to make alum Alum chemical for water treatment 4 Project Description PROJECT DESCRIPTION Water Treatment using fungi based polymer – no chemicals Objectives: 1. To transfer knowledge on application of biopolymer (based on AFlavus) to treat river water. 2. To create awareness, and promote adoption of, green and environmentally-friendly products 3. To show the superior efficacy of UPM’s A Flavus product in providing high water quality. BENEFIT: 1. Easy to produce locally 2. Low cost process 3. 100% natural - No toxic sludge 4. Able to treat pond and river water Methodology: 1. Design mini plant for treating water 2. Training program with Industry 3. Evaluation program on effectiveness of biopolymer to treat water 5 Project Description Project Concept A.flavus Bioreactor to produce biopolymer pH innoculum Our application … For factory or river water N T Attached biofilm reactor 100L Liquid biofloc (product) 65 L 65% yield 35 L Soft pellets Recovered for future use The Prototype (New) 2.7 lit/h Rapid mix 312 m3/d 13m3/hr 216 lit/min Floc tank Clean water Water treatment set-up for field trial 6 Project Activities PROJECT ACTIVITIES Formation of Design Team Selection of Process Types Fabrication of Pilot Plant Test and Commissioning Operation and Promotion Monitoring at Different Loads 7 Project Activities PROJECT ACTIVITIES - MILESTONE A site visit has been carried out by PMT Group staff to identified the most suitable location to locate the biopolymer and pilot plant on 13th and 15th December 2011. A design group meeting was carried out between UPM – PMT Group in the months February 2012 and April 2012. Water sampling has been carried out on 16th January 2012 and 8th February 2012 at 5 locations. The samples for all locations had been sent to the laboratory for analysis. Site Visit has been carried out on 31st January 2012 at Puncak Niaga Water Treatment Plant of Sg. Langat. A view inside the water treatment pilot plant showing the rapid mixing tank, coagulation and the floculation tank 8 Impacts to Industry/ Community IMPACTS TO INDUSTRY/ COMMUNITY The industrial partner (PMT) gets transfer of tech - new method of treating water. Company’s adoption of green product in their business and services. The product has created value added image to company –more competitive and open new venture. The strong ties between UPM-Industry enabled partnership with Local Authorities (MPSJ) to use the new product. Launching Serdang Green Town KTP project at public display 9 Impacts to Graduate Training IMPACTS TO GRADUATE TRAINING 2 postgraduate students are involved in the real world and current issues related with water treatment (1 PHD and I Master). The application of technology will be made in the practical sessions, sharing experience in design , construction and operation of water treatment plant A demo unit pilot plant is used as lifelong learning and engagement with users of technology. 10 FUTURE PLAN FUTURE PLAN – TREAT SERDANG LAKE AS PART OF SERDANG GREEN TOWN WITH MPSJ OPTION 1 Polluted Serdang Lake OPTION 3 OPTION 2 LEGEND: Inlet or outlet of water discharge Pilot Plant Cabin 11 Thank you www.eng.upm.edu.my www.pakar.com.my 12