Sorbents Workshop - National Response Team

advertisement

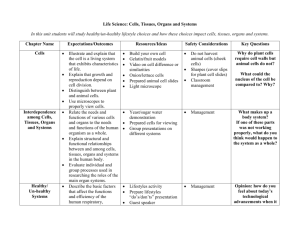

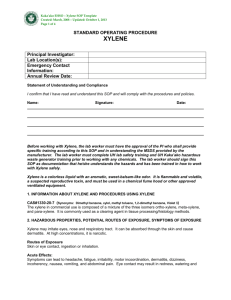

RRT 3 Meeting Rehoboth Beach, Delaware May 18th, 2011 OMB Circular A-119 (Public Law # 104-113). ASTM Performance Standards. Adsorbents – F-726. Absorbents – F-716. Thickeners/Solidifiers – F-726/716. Inorganic sorbents – include mineral products such as vermiculite, perlite, sand, clay (alumina silicates), activated carbon, pozzolanic rock. All of these materials rely upon liquids coating surfaces, both external and internal. Adsorbents by definition. Cellulosic and Synthetic materials. Cellulosic – comprised of carbon elements, naturally occurring materials such as wood chips, feathers, ground corncobs, peat moss, cotton, diatomaceous earth, etc. Adsorbent by definition. Comprised of carbon elements but manmade “surface-coating” materials such as polypropylene, polyurethane, polyethylene. Adsorbent by definition. Others – cross-linked polymers and rubber compounds that “swell” in liquids are Absorbents by definition. Polypropylene - adsorbent. 1950s – Naval Research Labs – micro – filter applications. 1960s – Exxon develops mb-pp process. 1970s – Exxon patents & processes in place. 3M and K-C primary downstream marketers. 1989 – Exxon Valdez boosts New Pig, SPC and dozens of others. Super-Absorbents Polymers (SAPs) 1960s – P&G develop “water-sensitive” polymers (polyacrylates/polyacrylamides), to become known as “Pampers®”. Revolutionize personal health care industry. 1970s – Dow Chemical develops “oilsensitive” polymers (alkyl styrene copolymers), to become known as Imbiber Beads®. SAP unique to the entire sorbent industry. Solidifiers 1960s – Shell Chemical invents styrenic block copolymers as hot-melt adhesives, asphalt additives, moulded thermoplastics, others. 1992 – Exxon investigates use of polystyrene in combination with polybutadiene, polyisoprene (rubber) as a sorbent material. 2003/2004 – Selection Guide “Alternative Response Technologies” & Pre-Approval for use. “Disclaimer: [Product Name] is on the U.S. Environmental Protection Agency’s NCP Product Schedule. This listing does NOT mean that EPA approves, recommends, licenses, certifies, or authorizes the use of [Product Name] on an oil discharge. The listing means only that data have been submitted to EPA as required by subpart J of the National Contingency Plan, Section 300.915. (Source: 40 CFR §300.920 (e))” 10 Solidifier Products 1 oil-sensitive SAP. Representative Test Liquids : Mineral Spirits – household cleaning solvent. SAE 10 W 30 – typical refined lubricating oil. # 2 Diesel Fuel – aliphatic transportation fuel. Gasoline – aromatic transportation fuel. Xylene – aromatic BTEX-type solvent. Note – crude oil very difficult to obtain. To determine effectiveness of test Products to completely “immobilize” test Liquids within given time-frame. To determine effectiveness of test Products to completely immobilize test Liquids using variable volumes of test Liquids. Observable “free” liquids within test containers after time limit considered a failure. Product/Liquid mix “slump” @ 15-30°angle considered a failure. 1. 2. 3. 4. 5. Elimination of “free” liquids means: Elimination of secondary contamination of personnel versus adsorbents. Elimination of secondary contamination of the environment versus adsorbents. Significant reduction of concentration-in-air of toxic and/or explosive vapors. Concentration-in-air often to below LEL. Waste disposal minimized. Gasoline spill during loading operations. Colourless? Where is it? Explosive vapours? Toxic Vapours? SOP – foam or evaporate/dissipate? Toxicity Considerations Fuels & solvents near urban centers? Product samples assigned Product Code #s. Volume ratios of test product to volume ratios of test liquid determined at 1:1; 1:2; 1:4; & 1:8. Test products added to test liquids to simulate spill application. Test products allowed to stand for 3 hours @ 20° C / 68° F. Note – Bulk density of test solidifiers approx. ½ of test SAP. Solidifiers (Product Code #s 101, 102, 103, 104, 201, 202, 203, 205, 206) – Failed all tests @ all ratios with all test liquids. Solidifier (Product Code # 204) Failed all tests @ 1:8 volume ratio. Immobilized Diesel Fuel & Mineral Spirits @ 1:4 volume ratio. Failed on Gasoline & Xylene @ 1:4 volume ratio. Failed on Xylene @ 1:2 volume ratio. Immobilized Xylene @ 1:1 volume ratio. Immobilized 4 remaining test liquids @ 1:1 & 1:2 ratios. Super-Absorbent Polymer (Product Code # 301). Failed to immobilize SAE 10W30 test liquid @ all volume ratios. Immobilized gasoline, xylene, diesel fuel & mineral spirit test liquids at all volume ratios. “Swelling” of SAPs means they will absorb several times their volume of liquids. All solidifiers are not created equal. All of the solidifiers dissolved to varying degrees in excess liquid as per ASTM specs. Particle size played a role in the speed of the reaction. Aggressive solvents such as gasoline and xylene were more difficult to handle. The SAP was able to immobilize several volumes of solvent due its swelling, as per ASTM specs. 1989 Exxon Valdez – recovery rates 10 – 15% 2010 Deepwater Horizon – recovery rates 10 – 15%. Heavy reliance on disposal technologies such as dispersants and in-situ burning. Chemical recovery almost non-existent. Failure of mechanical recovery techniques to adapt and look for innovations. Time for change? “You must be the change you want to see in the world” (Mahatma Ghandi,1869 – 1948) Thank You for Your Interest.