Poster-Fruit Drying - National Ag Risk Education Library

advertisement

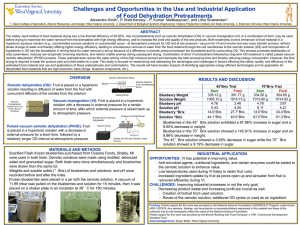

DRYING SURPLUS FRUIT – ADDING VALUE TO INCREASE FOOD SAFETY, YIELD, EFFICIENCY AND SUSTAINABILITY FOR WEST VIRGINIA FRUIT OPERATIONS Litha 1 Sivanandan , Alexandra 2 Smith , Kaushlendra 2 Singh , Winifred W. 3 McGee , Brett 2 Kenney , Jacek 2 Jaczynski , Judy 1 Matlick , Brenda 1 Porter 1. Extension Service; West Virginia University, 2. Davis College of Agriculture, Natural Resources, and Design; West Virginia University, 3. Penn State Extension; Pennsylvania State University. ABSTRACT METHODS West Virginia fruit producers regularly face production and marketing risk, in that they are frequently unable to sell all the fruit grown. Since the cost of production remains the same, whether fruit is sold, left un-harvested, or harvested then discarded, it is important to convert the surplus into a valuable commodity, such as shelf-stable dried fruit. Fruit may then be sold direct to consumers, or whole-sale to value-added producers, generating revenues. WVU research indicates that pre-treatments such as fruit firming and/or osmotic dehydration (OD) drying are affordable options for small-scale producers. OD results in moisture loss and sugar solids gain, thus improving the overall quality and food safety of the dried fruit products. Spent osmotic solutions (SOS) can be converted into value-added bio-products using hydrothermal treatment, thereby eliminating regulatory treatment requirements for waste disposal. INTRODUCTION Materials: o 1500g of Sugar Solution (or juice concentrate) 675 grams Sugar+ 825 ml Distilled Water (45°Brix) 975 grams Sugar+ 525 ml Distilled Water (65°Brix) o 500grams of frozen, scarified berries Equipment: o Vacuum Chamber o Compressed Air/Vacuum Pump o Refractometer @$1,400(to measure sugar in °Brix) o Steam jacketed mixing with agitator ($200) o Conventional food dehydrator ($100) o Water activity meter @$2,400 (to measure water activity) RESULTS/OUTCOMES 50.0 Water Activity 49.0 Air Tank Percent Yield 48.0 46.0 44.0 41.1 42.0 40.0 38.0 0.75 0.74 0.73 0.72 0.71 0.7 0.69 0.68 0.67 0.66 0.65 0.7398 0.7171 0.7003 0.6602 45°Brix/25°C 36.0 45°Brix/50°C 65°Brix/25°C 65°Brix/50°C Solution Concentration*Temperature 45 65 Solution Concentration in °Brix Effect of Solution Concentration and Temperature on Final Water Activity Effect of Solution Concentration on Percent Yield After Conventional Drying 50.0 47 48.0 48.0 Percent Yield EQUIPMENT/MATERIALS Incubator Percent Yield Osmotic dehydration (OD): Fruit is placed in a hypertonic solution (juice concentrate/sugar) resulting in diffusion of water from the fruit with Osmotic Dehydration concurrent diffusion of the solutes from the solution. Chamber Vacuum impregnation (VI): Fruit is placed in a hypertonic solution with a 1:3g/g decrease in external pressure for a certain amount of time; after which Fruit to Solution external pressure is raised back up to atmospheric pressure. Shaker Plate Pulsed vacuum osmotic dehydration (PVOD): Fruit is placed in a Schematic of osmotic hypertonic solution with a decrease in external pressure for a short time, dehydration apparatus. followed by a relatively longer OD interval at atmospheric pressure. Fruit firming: Some fruits are susceptible to textural quality changes during ripening. Pectin methyl esterase (PME) removes methyl ester groups from Vacuum the cell wall pectin constituents, which are accessible to depolymerization Pump Vacuum by polygalacturonase, reducing intercellular adhesiveness and tissue Chamber rigidity, and fruit firmness, making fruit-firming a necessary pretreatment. Research has shown that fruits treated with PME and calcium compound improves its firmness. Osmotic Value-added bio-products using hydrothermal treatment: Hydrothermal Dehydration Chamber carbonization (HTC) is defined as a mild form of pyrolysis using an aqueous 1:3g/g Fruit feedstock. During HTC, biomass is treated in hot compressed water to Solution yielding three product forms: solid hydrochar, aqueous compounds, and Schematic of the Pulsed Vacuum gases. The hydrochar isolates carbon and serves as chemical adsorbate Osmotic Dehydration Apparatus. media for other environmental applications. Fruit drying research and its industrial applications were disseminated through a series of Extension hands-on workshops (2011-2014) for educators, agricultural service providers, entrepreneurs, and prospective entrepreneurs. The resulting 6-hour intensive hands-on training workshops focused on various processes and equipment needed for increased fruit food safety, overall quality, yield, process efficiency, risks management, target market identification, and utilization of waste for bio-product applications. OD: Scarified, frozen blueberries were placed in sugar syrup concentrations of 65°Brix with a fruit to syrup ratio of 1:3 g/g. Fruit and syrup were heated at 50°C for 4 hours with occasional stirring. Weight of fruit was taken before and after processing for calculating yield. Conventional dehydration was used after osmotic dehydration at 135°F for 6.5 hours. Sunflower oil was applied to prevent stickiness and to provide a glossy appearance. Fruit-Firming: PME and calcium chloride was dissolved in water at 105°F. One pound of frozen strawberries was heated at 105°F in the above solution for two hours. The solution was drained and fruit was processed as stated above in OD section; drying time might be longer than blueberries. SOS: Fruit leather preparation, re-concentrating and re-using the syrup etc. are food product development options trained during the Extension workshops. HTC: Direct benefits for producing high functionality hydrochar were discussed. Additionally, indirect benefit Conventional for saving millions of gallons of fresh water needed to Dehydrationreduce biochemical oxygen demand, pH, and total 135°F, 6.5 hours soluble solids to meet regulatory standards, and capturing SOS-carbon, reducing green house gas emission in light of current federal and state regulations. 46.0 44.1 44.0 42.7 42.0 46 45 44 180 240 OD Time in Minutes Effect of OD Time on Percent Yield After Conventional Drying 300 43.3 43 42 41 40.0 46.5 25 50 Temperature in °C Effect of OD Temperature on Percent Yield After Conventional Drying Workshops: Hands-on training combined with risk management education, food safety measures, and sustainability has been an attractive package for participants. Decreased waste, inexpensive costs, high yields (=$$), and shelfstable products were appealing for entrepreneurs. 100% of the participants wanted to learn more about application of these techniques and were willing to attend another workshop however limited resources restrict us from providing these workshops and workshops for specific product (fruit) for each region. Funding: Partial support from National Science Foundation's ADVANCE IT Program under Award HRD-1007978. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. Partial support from Branch Banking and Trust Company’s CRA / Community Development Donation Fund. Partial support from Northeast SARE Professional Development Grant# ENE12-125 Acknowledgements: Susan Slider, Brett Kenney, West Virginia University.