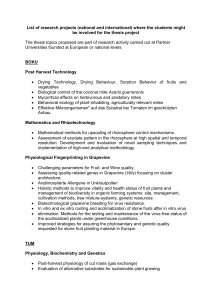

South African Export Markets

For the industry, by the industry

Michelle Kruger: 083 703 4373

History of fruit industry:

• Roots stretches back to middle of 17 th century

• Exports to UK, Netherlands and other parts of Europe at the end of the 19 th century

• Now exporting to more than 70 countries worldwide

South African Export Markets

Canada/USA:

5%

UK: 22%

Europe:

33%

Russia:

Middle East:

10%

18%

Far East: 10%

Indian Ocean Islands: 1%

Africa: 1%

What to have in place when you want to export your fruit

1. Register on DoAs food data base for a PUC and/or PHC. Go to www.nda.agric.gov

2. Contact local PPECB offices. Nelspruit – Koos Retief 013 755 2879

3. Register for SA GAP or Global GAP and/or SA GMP. PPECB can assist.

International quality, environmental and food safety systems:

International quality control systems

ISO 14001

Nature’s Choice (Tesco)

Globalgap (certain European retailers)

LEAF (Waitrose)

The British Retail Consortium (BRC) Global

Food Standards

HACCP

Purpose and where it applies

Sets standards for protecting the environment

Applies to farms and on-farm packhouses

Applies to farms and on-farm packhouses

Applies to farms supplying Waitrose

Applies to pack houses supplying British retailers

Applies to pack houses

The importance of traceability:

• Any problem can be linked to a specific producer instead of a whole group

• Fast, accurate and limits risk

• Limits unnecessary costs

• Limits public concerns

Carton Marking:

• Product of SA

• Class of product

• Name of exporter and/or pack house

• PUC code

• Product type

• Variety

• Count (size)

Fruit Type

Grapes

Avocados

Apples

Pears

Stone Fruit

Citrus

Optimum temperatures

Optimum temperature in degrees Celsius

-0.5 to 0°C

3.3 to 4.4°C

-1.1 to 4.4°C

-1.5 to 0°C

-1.1 to 0°C

4 to 5°C

Practical shelf life

(PSL)

Up to 150 days

14 to 28 days

90 to 240 days

60 to 180 days

14 to 35 days

Oranges: 35 to 90 days

Lemons: 30 to 120 days

Documents completed in the export process

•

Customs: DD550

•

Port Authorities: Cargo dues order and terminal container order

•

Agricultural Authorities: PPECB – Export inspection certificate; DoA phytosanitary certificate

•

Terminals: Mate’s receipt

•

Shipping Line: Bill of lading

•

Origin documents

Why South Africa is well-suited for large scale production of fresh fruit:

• Relatively low labour costs

• Availability of land

• Wide variety of climatic zones

• Well developed infra structure

• Counter seasonal production to

Northern Hemisphere

Challenges for SA fruit industry:

• Oversupply of fruit

• Withdrawn subsidies from government

• New legislation from importing countries

• Global crisis

• Increasingly competitive international export markets (Chile, Brazil)

• Downward pressure on produce prices retailers

• Burdensome input costs from monopolies and cartels

• The price of crude oil

• Fluctuation of the exchange rate

• Successful land reform

Solutions:

• Increase in quality

• Market driven industry - not production driven

• Open new markets

• Develop the local market

• Sell expertise to counter seasonal markets

• Generic promotions

• Continued education – Top of the Class programme

• Established 1998 as non profit organisation

• Membership voluntary

• Approximately 60 members which export 76% of all fresh fruit exported from SA

• Strict code of conduct

• Members are exporters (agents and traders), producer exporters, service providers and other industry organisations

FPEF objectives for 2008

• Assist members to find international markets for their principals’ fruit

• Promote the FPEF members collectively within producer circles

• Continue to refine the accreditation criteria

• Facilitate access to relevant, accurate and timely generic information

• Sourcing of funds for projects within the industry

• Provide innovation for its members in the value chain – Post Harvest Innovation Programme

• Continued education in the value chain – Top of the Class programme

Five main stages of the export process:

1. Pre-season planning with producers

2. Buying fruit and contracting with the producers and service providers

3. Marketing the fruit

4. Managing operations during the season

5. Analysing the previous season

Roles played by the exporter:

1. Ensuring all documents are properly completed at each stage

2. Delivering a quality product from the farm to the consumer

3. Satisfying buyers

4. Making sure that products and packaging compete with competitors

5. Controlling costs in the value chain