8_PP9_WaterSafetyPlans_2012

advertisement

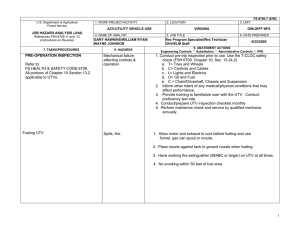

2nd International Conference Graz October, 10th 2012 Water Safety Plans PP8 (Germany) PP7 (Scottland) PP9 (Austria) Harald Schmölzer Franz Gundacker Content History of Water Safety Plans W88 - General Information Overview of procedure Implementation in 8 Steps Conclusions History of Water Safety Plan Guidelines for Drinking-Water Quality, 3rd edition, 2001 Chapter 4: Water safety plans Aim: „ Good safe drinking water that has the trust of consumers“ Proposal: September 2004 • The American Water Works Association (USA) • The Awwa Research Foundation (USA) • The Cooperative Research Centre for Water Quality and Treatment (Australia) • Deutsche Vereinigung des Gas-und Wasserfaches e.V. (BRD) • The Drinking Water Inspectorate (England and Wales) • UK Water Industry Research (UK) • United States Environmental Protection Agency (USA) • Water Services Association of Australia (Australia) WSP-Conception of WHO Activities in Austria The ÖVGW (Austrian Association for Gas and Water) prepared and published Guideline W88 (Manual for the introduction of a simple water safety plan) – May 2008 Designed for small drinking water facilities Some Austrian Water Suppliers have employed WSP Translation of the Guideline W88 (English version) during the SHARP-Project (PP8 – Germany, PP7 – UK) W88 - General Informations Drinking water is our most important necessity – high demands on water supply services regarding hygiene, security and protection of ressources The operator is in charge for a correct operation of a water supply installation and for hygienic drinking water. The high quality of drinking water only can be ensured by preventive quality assurance and permanent quality control. physical / chemical/ microbiological condition, technical eminent parameters have to be detected early and - if necessary - avoided. W88 - General Informations this guideline offers a manual and support for the implementation of a product- and process-orientated quality-management-system, with which regularily all processes of a water supply service can be checked and improved. Hazard-identification and risk evaluation are the first steps necessary for a management system. This guideline uses, the actual WHO recommendations, many principles and concepts of the HACCP – method (Hazardous Analysis and Critical Control Point), which is implemented in the rest of the food industry. W88 - Areas of Application • This guideline is a master profile for the organisation and systematisation of drinking water – related management practises. The guideline defines the terms hazard identification and risk evaluation, which mark the starting point for setting up a system management. This guideline particularly applies to small drinking water facilities. • With clear work instruction in eight steps - illustrated with examples and supplemented with sample forms – this guideline is a reference for setting up a system for selfchecking. W88 - Overview of procedure Step Content Support and Form 1b “description of operation” 2 Creating or updating the inventory of the entire water supply system. 3 Looking for possible hazards of water supply evaluate and list the critical points. 4 Implementation of one-off measures to eliminate or reduce hazards. standard form 4a "Risk elimination" and 4b 'action plan' 5 Creating or updating instructions for maintenance. standard form 5 „Maintenance Instructions” 6 Create instructions for control of critical issues. standard form 6 “Control point instruction” 7 Follow instructions in everyday life and monitor and evaluate results. Protocol/Minutes – Example Figure 8 page 19 8 Preparing annual assessment on water, facilities, processes and proposals and implementation of the organization and improvement. Checklist "water supply" Figure 10 Page 22 internal audi Form 2 "data base" System strucure Checklists 3a “hazards” Form 3b "risk assessment" practice system 1 Appraisal Form 1a "organization of water supply" Organization of water supply company description of duties and expertise of employees. W88 - Overview of procedure 2 Organization of water supply company description of duties and expertise of employees. Creating or updating the inventory of the entire water supply system. 3 Looking for possible hazards of water supply evaluate and list the critical points. 4 Implementation of one-off measures to eliminate or reduce hazards. 5 Creating or updating instructions for maintenance. 6 Create instructions for control of critical issues. 7 Follow instructions in everyday life and monitor and evaluate results. 8 Preparing annual assessment on water, facilities, processes and proposals and implementation of the organization and improvement. System strucure 1 Support Appraisal Content Checklist "water supply" Figure 10 Page 22 internal audi practice system Step W88 - Overview of procedure 1 Organization of water supply company description of duties and expertise of employees. 2 Creating or updating the inventory of the entire water supply system. 3 Looking for possible hazards of water supply evaluate and list the critical points 4 Implementation of one-off measures to eliminate or reduce hazards. 5 Creating or updating instructions for maintenance 6 Create instructions for control of critical issues 7 Follow instructions in everyday life and monitor and evaluate results. 8 Preparing annual assessment on water, facilities, processes and proposals and implementation of the organization and improvement. Appraisal Support System strucure Content practice system Step W88 - Overview of procedure Organization of water supply company description of duties and expertise of employees. 2 Creating or updating the inventory of the entire water supply system. 3 Looking for possible hazards of water supply evaluate and list the critical points. 4 Implementation of one-off measures to eliminate or reduce hazards. 5 Creating or updating instructions for maintenance. 6 Create instructions for control of critical issues. 7 8 Follow instructions in everyday life and monitor and evaluate results Preparing annual assessment on water, facilities, processes and proposals and implementation of the organization and improvement Appraisal 1 Support System strucure Content practice system Step Organisation, responsibilities and expertise Step 1: Description of organization of water supply and tasks and expertise of staff (job description) Order 1: Create an organizational description of the water supply company.(Organizational chart with the supervisor of the manager) and job description and qualifications of the manager and their employees Inventory of water supply Step 2: Updating or writing of the inventory of water supply system Order 2: Update or create the map of project area and the facility scheme and create a list of main facilities. They also collect the current data base for the entire water supply Map of project area System Diagram Assessment of water supply Step 3: Looking for/Search and assessment of potential risks to water supply and listing of critical points Order 3: Search all potential hazards in the whole water supply by using the checklist “hazards” Evaluate the potential hazards and document the detected critical points in the form and in the general plans by using the form ”risk assessments” Catchment area and Protected Zone Hazard 1.4 Liquid fertilizer tank: risk of leakage 1.5 Dunghill: danger of seepage 3.1 Fertilizer: into the groundwater 3.2 Pesticides: into the groundwater 4.1 Street: risk from leaking oil, petrol in an accident 5.1 Brook: Risk of polluted surface water 5.2 Brook: Risk of Flooding 6.5 Contaminated sites, landfills risk of leakage Requirements for a collection tank for spring water Requirements 7.0 Shaft height at least 30 cm above ground level 7.1 Manhole cover: lockable, rainwater proof, ventilation 7.2 Entrance below the water table 7.3 tight structure 7.3 Inflow is located 20 cm above the highest water level 7.3 corrosion-resistant pipes, water pressure-resistant pipe penetration 7.4 Drain / overflow frog flap, min. DN 100, siphon 7.5 Supply line with water meter and gate valve Elimination of hazards at critical points Step 4: Implementation of temporary measures to eliminate or reduce hazards at critical points Order 4: Eliminate all eliminable hazards at reasonable cost, using the standard form "Elimination of dangers" to the final success control. Enter in the standard form “action plan” long-term and costly measures with priority and time. Reduction of hazards at critical points by maintenance Step 5: Updating or creation of instructions for maintenance Order 5: Update for the critical points of the existing maintenance instructions or create new maintenance instructions Risk managements at critical points through controls Step 6: Preparation of instructions for control of critical points Order 6: Create for all remaining critical points, a control point directive "control point". Practical implementation of the instructions Step 7: Follow instructions in everyday life and reporting and evaluation of results Order 7: Instruct the responsible staff and make sure that all maintenance instructions and all control point instructions are strictly observed and record the relevant activities and findings in everyday life. Initiate if required by error message, the necessary corrective action Annual evaluation of water supply Step 8: Preparation of annual evaluation of water, plants, processes and organization and propose and implement of improvements Order 8: Create a comprehensive annual assessment of water quality and the influence of the systems, processes and quality management organization. You should also assess the accuracy and completeness of the instructions. Create a short written report and initiate improvements if needed Water levels years recording showing the variation range from 1973 (source Graz water) Conclusions WSP is a general quality management tool for drinking water suppliers in order to safe drinking water quality. Hazard-identification and risk evaluation on the principles of the HACCP – conception (Hazard Analysis and Critical Control Point) This guideline worked out by the Austrian Association for Gas and Water (OVGW) particularly applies to small drinking water facilities in Austria. The WSP guidance can also be useful for drinking water facilities all over Europe