Kirk Bridgewood, DETS - Waste Derived Fuels

advertisement

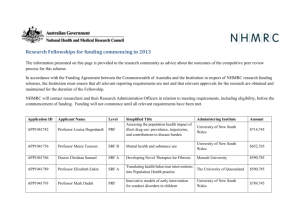

Waste Derived Fuels NERF, 6th June 2013 Kirk Bridgewood Derwentside Environmental Testing Services DETS – dependable data, dependable delivery Overview o Introduction o What is the difference between RDF and SRF o What legislation covers WDFs o Why do I need to test WDFs- what is required o How do I sample a WDF o What are the markets for WDFs o How to ensure a consistent quality / specification for a WDF Introduction Waste Derived Fuel (WDF) a heterogeneous group of nonhazardous wastes that do not cease to be such by virtue of their being used to generate energy without greater negative environmental impact than landfill disposal Introduction • Many views, both positive and negative however: – Recovering energy from waste is playing an increasing role in generating ‘low carbon’ energy and will support achievement of the UK’s target of 15% of its energy from renewable sources by 2020. (WRAP, 2012) – ‘Government supports efficient energy recovery from residual waste which can deliver environmental benefits, reduce carbon impacts and provide economic opportunities. Our aim is to get the most energy out of waste, not to get the most waste into energy’. What legislation covers WDFs Legislation • Environmental Permitting (England and Wales) Regulations 2010 • The Industrial Emissions Directive (IED) 2010/75/EU – The Waste Incineration Directive (WID) has been recast within the IED. Provisions relating to gasification and pyrolysis have been introduced. • Revised Waste Framework Directive (2008) – Recognises recovery, and EfW and places efficiency standards on EfW plants (R1) that requires the use of heat energy produced. Revised waste hierarchy Releasing the energy bound within this waste (which would otherwise go to landfill) is a sensible and sustainable solution. What is the difference between RDF and SRF? RDF vs. SRF • RDF - refers to a combustible, moderate Calorific Value (CV) waste fraction (e.g. paper, card, wood, and plastic) produced by the mechanical treatment of municipal or similar commercial / industrial waste – – – – Limited processing No quality management system Limited quality control Typical markets include EfW in the UK and Europe • SRF as with RDF but prepared to a quality specification e.g. CEN 343 – Using quality management techniques • An SRF is not necessarily higher specification fuel than RDF, but there is greater consistency in the properties required Why do I need to test WDFs and what’s involved Testing WDFs • WDFs are defined by their physical and chemical properties. – Determination of chemical properties in particular required testing • Properties that define WDFs are often grouped into economic, technical and environmental and include: • • • • • • • • Gross and Net Calorific Value Moisture Content Ash Content Volatile Matter Elemental analysis Metals analysis Halides Bulk Density • • • • • • Particle Size Distribution Composition (percentage paper, metals, plastic etc.) Biomass content Ash melting properties Density Mechanical Durability WDF testing in practice Sample preparation • Mass reduction • Size reduction Key properties • Moisture • Bulk Density • Calorific Value • Biomass • Metals • Chlorine How do I sample WDFs for testing? Importance of Sampling 1000 tonnes Why Do We Need a Sampling Plan ? • To give a consistent approach and repeatability of samples • Analysis is carried out on a representative sample. Which in turn allows • Classification of WDF materials for end users • Prevention of rejected loads and give confidence in supplied materials to end users. 1 gram Sampling Plan design Four elements to designing and undertaking sampling of WDF: 1. Sample size 2. Number of samples 3. Method for collecting samples 4. When and where to collect samples Adapted from BS 15442:2011 for WRAP WDF guidance What are the markets for WDFs? WDF Markets Users of WDF’s – – – – – – – EfW plants (UK and Europe) Heating and Power Plants1 Cement Kilns Lime Kilns Iron and Steel Production Non-ferrous Metal Production Brick Production RDF SRF • Important to note that the above users (exc. Small scale unit) typically charge a gate fee. 1inc. small scale CHP units for individual companies How RDF and SRF compare Physiochemical properties Parameter RDF Net Calorific Value MJ/Kg Increased cost in processing is balanced out by reduction in gate fee and could be argued - has more market potential Moisture Content wt/wt % Ash Content wt/wt % SRF 7 -16 16-24 18 - 50 5-18 5- 20 <10 <850 <450 <3 <1 Bulk Density kg/m3 Other Heavy Metals mg/Kg (list of WID / ID metals) Chlorine wt/wt% Economic factors Gate fee (per tonne) £60 £35 Difference Processing costs (raw feed to final fuel) per tonne Difference taking into account processing and gate fees combined £25 £12 £25 £22 Important to note – figures used are only estimated . Specification values are taken from what DETS have tested reference to the type of material specified by the labelling. How to bench mark WDFs Classification schemes • Quality management assurance and classification systems – CEN 343 sets out quality control and classification system – WRAP recently launched a WDF classification system – Both systems group WDF properties into three groups: • Economic • Environmental • Technical (operational) WRAP classification system ‘A Classification Scheme to Define the Quality of Waste Derived Fuels’ WRAP classification system WRAP classification system Any Questions? Contact Details: Derwentside Environmental Testing Services Ltd Unit 2, Park Road Industrial Estate Consett Co Durham DH8 5PY Tel: +44 (0)1207 582333 Email: info@dets.co.uk