HassanSahudenJanelleBurdPOLPlanningStudies

advertisement

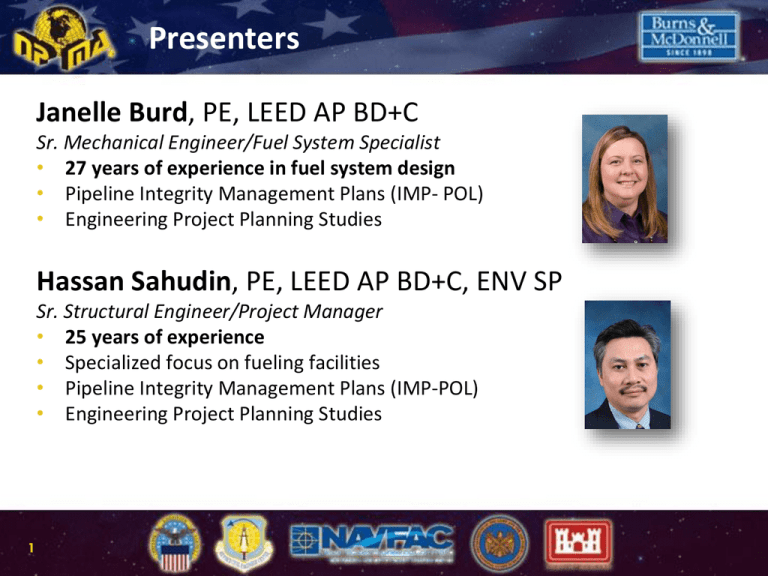

Presenters Janelle Burd, PE, LEED AP BD+C Sr. Mechanical Engineer/Fuel System Specialist • 27 years of experience in fuel system design • Pipeline Integrity Management Plans (IMP- POL) • Engineering Project Planning Studies Hassan Sahudin, PE, LEED AP BD+C, ENV SP Sr. Structural Engineer/Project Manager • 25 years of experience • Specialized focus on fueling facilities • Pipeline Integrity Management Plans (IMP-POL) • Engineering Project Planning Studies 1 PETRO Expo 2013 Pipeline Integrity Management Plan (IMP-POL) and Project Planning Studies (PPS) Common Deficiencies 18 November 2013 Agenda • Burns & McDonnell Overview • IMP- POL’s & Planning Studies • Assessment Objectives • 3 Most Common Deficiencies Pipe Support Thermal Relief Containment • Additional Deficiencies • Conclusion • Q &A 3 Burns & McDonnell Overview: • • • • • • • • Founded in 1898 100% Employee-Owned Over 4,300 Employees $2B in Revenues per year More than 30 Offices We deliver successful DOD projects worldwide 50+ years of experience in design, construction, inspection and operational assistance of POL facilities Partners include AFCEC, USACE, NAVFAC, National Guard, Reserves, DLA HQ, DLA-Energy Our Mission: “Make Our Clients Successful” 4 U.S. POL/Fueling Project Sites 5 International Fueling Project Sites 6 IMP-POL and PPS Sites IMP-POL: • 6 Regions total 57 sites completed 17 sites future • Follow-On IMP: 1 site in US 2 sites in Japan Project Planning Study (PPS): • 14 sites in US • 1 each in Italy, Greece, Gitmo 7 IMP-POL and Project Planning Studies What is an IMP-POL and Project Planning Study? • Funded by Defense Logistic Agency – Energy (DLA-Energy) • Two Parts of DLA-Energy’s Centrally Managed Program (CMP) • Condition assessment programs Piers and Marine Loading Arms Project Planning Study (PPS) Cathodic Protection System Integrity Management 8 Automated Fuel Service Station Automatic Tank Gauging Tank Integrity Management (API 653 & STI) Terminal Automation Pipeline Integrity Management Plan (IMP-POL) Pipeline Pressure Testing (API 570) Rail Maintenance Pressure Vessel Inspection (API 510) Hydrant System Tuning (upcoming) Ultimate Goal Ultimate Goal for DLA-Energy and Installations: • Provide site specific record for each facility Condition assessment Testing and inspection Intervals Responsible execution agency • Plan and fund projects, improvements and repairs • Risk management 9 Typical Codes and Standards • Local, State, and Federal Environment Governing Standards • API and ASME • NFPA 30, Flammable and Combustible Liquids Code • UFC 3-460-01, Petroleum Fuel Facilities • UFC 3-460-03, Maintenance of Petroleum Systems • UFGS-01 35 29, Safety and Occupational Health Requirements • 33 CFR 156, Oil and Hazardous Material Transfer Operations • 40 CFR 112, Oil Pollution Prevention • 49 CFR 195, Transportation of Hazardous Liquids by Pipeline • DESC-P-12 - DLA-E / DESC Sustainment, Restoration and Modernization (SRM) Funding Policy for Fixed Petroleum Facilities 10 Assessment Objectives Provide DLA-E and Base Fuels Personnel with: • Assessment of facilities conditions and pipeline integrity • Overview and understanding of existing POL infrastructure • Record of the general integrity and condition of the piping systems • A “road map” of integrity management and maintenance • Identification of highest-risk elements • Recommendations for further actions 11 IMP-POL – Common Deficiencies Common Deficiencies found during site assessments: 12 • Pipe Support Issues • Thermal Relief Issues • Valve and Flange Seals – Weeps and Leaks • Soft Materials – Brass and Bronze Valves and Piping • Galvanic Reactions – Dissimilar Metals • Soil-Air / Concrete-Air Interfaces • Coating Failure • Cathodic Protection Issues Planning Studies – Issues Common Deficiencies found during site assessments: 13 • Pipe Support Issues • Thermal Relief Issues • Secondary Containment Issues • Insufficient Fuel Lab Ventilation • Corrosion/Coating Failure • Lighting Issues • Use of Sight Flow Indicators • Lack of EFSO Stations • Grounding Issues 3 Most Common Deficiencies Pipe Support Thermal Relief Secondary Containment 14 Deficiency 1 - Pipe Support Issues: • Lack of Isolation Pads • Concrete Saddles • Support failure • Temporary Supports • Inadequate Support • No Lateral Restraint • Spring Can Supports Disengaged 15 Pipe Support Lacks Isolation Pad Metal-metal contact 16 Pipe Support Concrete Saddle Concrete-steel contact, moisture collection 17 Pipe Support “Clamshell” anchors Moisture collection 18 Pipe Support Metal Roller Supports Metal-metal contact 19 Pipe Support “Spider” Supports Corrosion, displaced support 20 Pipe Support Improper pipe supports Lacks Lateral Restraint 21 Risks: Pipe Support Risks from Undetected/Unaddressed Issues: • Excessive pipe movements • Pipe or joint failure • Equipment and Tank Damage • Unintended release • Environmental impact • System shut down • Impact to mission 22 Risk Mitigation: Pipe Support Risk Mitigation Recommendations: • Metal to Metal contact – Teflon barriers, pads, pipe collars • Concrete saddles – Replace with approved pipe support • Support failure – Perform pipe stress analysis and replace • Wood support – Replace with approved material • Inadequate Support – Replace with appropriate style Owner Impact – Preventative maintenance is less costly than equipment repair/ replacement and potential environmental clean up 23 Deficiency 2 - Thermal Relief Issues: • Insufficient Thermal Relief • Cascading Issues • Improper Setting • Thermal Reliefs Not Tested • Closed Isolation Valves The internal pipe pressure increase resulting from fluid thermal expansion can equal as much as 75 psi for every degree rise in the fuel temperature if not relieved! 24 Thermal Relief Risks Risks from Undetected and Unaddressed Issues: • • • • 25 Over pressurization of equipment and valves – Costly repairs and replacement Leaking Flanges and Joints – Increased maintenance costs Danger to operators due to high system pressures Potential for catastrophic failure of pipe or components Thermal Relief Risk Mitigation Risk Mitigation Recommendations: • • Conduct a thermal relief study Change operating procedures – leave relief valve open Owner Impact – Preventative maintenance is less costly than equipment repair/ replacement and potential environmental clean up! 26 Deficiency 3 – Secondary Containment Regulations: 40 CFR Part 112, NFPA 30, and UFCs Issues: • Absence of Secondary Containment • Cracks in Containment Concrete • Joints Sealant Failure • Liner System Problems • Lack of Containment Curbs 27 Secondary Containment Absence of Containment Over Water Risk contamination of waterways 28 Secondary Containment Absence of Containment at Grade Risk ground contamination 29 Secondary Containment Absence of Containment Below Grade Risk groundwater contamination 30 Secondary Containment Cracks in Containment Concrete Breach in Containment 31 Secondary Containment Joint Sealant Failure Breach in Containment 32 Secondary Containment Liner System Problems Ineffective Containment 33 Secondary Containment Lack of Curbing Ineffective Containment 34 Secondary Containment Say What? Leak Detection Plant 35 Containment Risks Risks to unaddressed problems: • Inability to detect small leaks • Inability to contain fuel spills • Environmental impact • Non-compliance 36 Containment Risk Mitigation Risk Mitigation Recommendations: • Repair cracks in concrete • Seal joints with jet-fuel resistant sealant • Provide adequately sized secondary containment or remote spill containment system • Install perimeter curbs on equipment pads/pipe causeway Owner Impact – Preventative maintenance is less costly than equipment repair/ replacement and potential environmental clean up! 37 Additional Deficiencies Additional Deficiencies: • Brass/Bronze Bodied Valves • Sight Flow Indicators • Soil-Air / Concrete–Air Interfaces • Product Labeling • Lubricated Swivel Joints • Fuel Lab Inadequate Ventilation • Coating Failure • Dissimilar Metals • Inadequate Ground Clearance 38 Brass/Bronze Bodied Valves Issue: Soft bodied valves and piping such as brass, bronze and copper present in fueling system. Risk: NFPA 30 and 30A - Metals with lower melting point are not to be used in fueling systems. Recommended Mitigation: Remove and replace with UFC compliant valves and piping. UFC 3-460-01 - valves are to be CS or SS bodied. 39 Sight Flow Indicators Issue: Sight flow indicator in certain configurations are subject to tank head pressure or system pressure. Risks: Sight glass failure may cause significant leak UFC 3-460-01 - Sight flow indicators are not to be provided on thermal relief piping, filtration devices, or product recovery tanks. Recommendation: 40 Remove sight flow indicators in these configurations and repair the piping. Soil - Air Interface Issue: Piping is not properly coated. Risks: Deterioration of Extruded Polyethylene (UG pipe coating) coatings due to UV exposure Recommendation: Expose the soil/air interface, prep and coat 12 inches below grade level and 6 inches above. Heavy body, surface tolerant epoxy coating Compatible with polyethylene and the existing aboveground pipe coating. 41 Lubricated Swivel Joints Issues: Lack of proper maintenance/lubrication may cause seized joints Typically found at Truck Loading / Truck Offloading. (All Products) Risks: Compromised fuel quality (Aviation Fuel) UFC 3-460-01: Aluminum or SS non-lubricated swivel joints Recommendation: Replace with non-lubricated type swivel joints 42 Fuel Lab Inadequate Ventilation Issues: Inadequate ventilation rate Improper equipment Risks: Air quality concern Explosion hazard Recommendation: Replace with proper fume hood 43 Coating Failure Issue: Coating failure causing pipe corrosion Risks: Leaks in pipes Failure at supports. Recommendation: Clean and recoat Piping - UFGS Spec Section 09 97 13.27. 44 Dissimilar Metals Issues: Galvanic corrosion Risks: Failure of bolts Maintenance issue Recommendation: Provide isolation flange kit 45 Inadequate Ground Clearance Issues: Piping located too close to grade Risks: Corrosion Maintenance issue Recommendation: Raise piping 18” clearance min 46 Conclusion How thorough assessments help Bases/Installations: • Identify items with higher risks of failure • Recommend Mitigation Plans • Reminder of items requiring maintenance and repairs • Awareness of funding mechanism A well-qualified consultant is a critical partner in your success ! 47 Questions / Answers 48