PUMP STATION ELECTRICAL DESIGN

advertisement

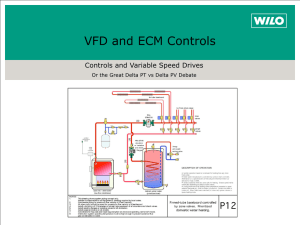

PUMP STATION ELECTRICAL DESIGN 40 Years Lessons Learned Maynard Wayne Robertson, PE, CEM mwrobertson@vaughnmelton.com mwrdcr@comcast.net TAUD Technology Conference Gatlinburg, TN March 13, 2013 Pump Station Design Requirements • Tennessee Dept. Environment & Conservation • Environmental Protection Agency • NFPA- 70- National Electrical Code • Tennessee Fire Marshall- Electrical Inspections • OSHA/TOSHA TDEC Requirements • General Design Requirements for Sewerage Works • Key Chapters for Pump Stations; 1, 2, 14 • Chapter 2. Section 2.5 Pump Stations • Alarm System and totalizers on All stations • 2.6.3 All wet well wiring to be Class l, Division l, per NEC • 2.7.3 PS Capacity Greater Than - 1.0 MGD Requires Flow Meters Requires Back Up Power System TDEC Requirements • Chapter 2.6.1.6 Requires to comply with All OSHA Rules. Work place safety. • Chapter 2.7- Operability/ Reliability Do you need generator/backup power? Essentially EPA requirements. • Reliability Class 1, Class 2, Class 3. TDEC • 2.5 Septicity Controls. I guess something that smells BAD. Do not make it smell worse. Setting controls for minimum time in wet well. • Auto Pump Out (Timed pump start after low level contact made, low cost to reduce odor ) • Electric Power Systems Chapter 1.3.11.5 • www.tn.gov/envionment/wpc/publications • Design Criteria for Sewerage Works National Electrical Code • Latest Version NEC-2011 • Next Version NEC-2014 • Code revised on Three Year Cycle • Version adopted in Tennessee NEC-2008 NFPA CHAPTER 70 • National Electric Code / 70E work place safety • NEC 2008 Used Statewide *Exceptions In Some Cities NEC-2011 • 70E Work Place General Safety Requirements • Installation Of Equipment • Protection Of Electrical Equipment NEC-2008 Organization • Chapters: One thru Nine Articles Tables Appendix • Chapters: One Thru Four Basic Wiring Requirements. Apply to all Wiring Installations. • Chapters: Five thru Nine Special Conditions NEC Chapters • • • • Chapter 1 – General Chapter 2 – Wiring and Protection Chapter 3- Wiring Methods and Materials Chapter 4 – Equipment for General Use • Chapter 5 – Special Occupancies • Chapter 6 – Special Equipment • Chapter 7 – Special Conditions • Chapter 8 – Communications Systems(Stands alone) • Chapter 9 – Tables • Annex A thru H ; Informational Only Key NEC Articles for Sewer Pump Stations Articles: 200, 215, 220, 240, 250, 310, 312, Table 310.16, 400, 430, 445, 500 & 700. Note: Entire Code Applies Always!! Tennessee State Fire Marshall • Requires Electrical Inspection of all New and Modified Electrical Installations. • Require Use of Listed Equipment- UL, etc. • Current Enforcement NEC -2008 • Authority Having Jurisdiction EPA • EPA-430-99-74-001 Operability and Reliability • Class 1 Standby Power nearly always required • Class 2 Standby Power maybe Required • Class 3 Normally not Required Service Terms • Service • Service Entrance • Metering • Service Disconnect • Service Type Overhead Underground • Single or Three Phase • Available fault Current NEC Voltage • Low Voltage = Less Than 600 Volts • Single Phase 120/240 Volts Motors 5 HP or Less( 7.5 & 10.0 are manufactured) • Three Phase 120/240 Volt Delta Connected 120/208 Volt Wye Connected 277/480 Volt Wye connected Electrical Service Entrance • Capacity for both pumps to operate • Service disconnect rated for service entrance and capacity to allow second motor to start without tripping • Service Equipment( Main Breaker and panel boards, etc.) rated for available fault current • Fault Currents can be high at PS as result of large transformer and short wire runs • Standard Interrupting capacity: 10,000, 22,000, 65,000amps • Grounding and Bonding • Adequate work space in front of electrical equipment • For outdoor locations shield panels from sun and heat Wiring Methods • NEC Article 250 Grounding and Bonding • Table 250.122 Size of Equipment Ground Conductor • Grounded Conductor • Ground Wire • Lightning protection • Table 310.16 /Table 310.15B(2)a, more than 3 conductors in raceway/conduit • Conductors Rated at 75C • Conductors Rated for Wet Location Control Panels • Correct NEMA Enclosure ( 3R, 4X, etc. ) • Ventilation/Cooling • Drains • Labeled (UL, CSA) • Alarms • Control Transformer (Reduce line Noise) • Instrumentation (Runtime, Volts, Amps, Calibration) Motor Starters • Manual • Across the Line starters( NEMA SIZE 0, 1, 2, etc.) • Part winding • Auto transformer • Soft Start • VFD (6 pulse more noise and 12 pulse less noise) • VFD noise may interfere with controls/SCADA PHASE CONVERSION • Single Phase Power to 3 Phase Power • Phase Conversion Using VFD • Size VFD Based On Single Phase Load Plus 15% 20Hp, 3P, 230V, FLA=54 Amp Based on single phase = 100 Amp Use 120 Amp VFD Common WWPS Problems • • • • • • • • • • Corrosion, Corrosion, Corrosion!!!! Electrical Junction Boxes in Wet Wells Excessive Pumps starts/ Short run time Unlisted Electrical Equipment (Inspector Rejects) FAILURE TO DERATE CONDUCTORS in Conduit. (more than three) Lack of Phase Loss Protection Phase to Phase Voltage/excessive voltage difference. Poor Electrical Grounding No Isolation of sewer gas from control Panels thru use of junction boxes with double conduit seals. Complete failure less than 1 year. Circuit Breakers too small, Result excessive heat in Panel. Common WWPS Problems • NO Conduit Seals, Sewer Gas direct line to control Panel. • Pump Rotation • Wrong NEMA Class Enclosures • Low Equipment Electrical withstand Ratings. • VFD noise on Control circuits • No GFIC Receptacles • Generators/ transfer switches improperly wired/ Phase Reversed. Checklist/Records • Always use startup Checklist • Voltage, Line to Line, Line to Ground, Phase to Phase • Amperes • Discharge Head • Pumping Rate • Photos • Nameplate Data • Terminals Tight WWPS Life Cycle Cost • Initial Cost • Installation • Commissioning Cost • Maintenance and Repairs Cost • ENERGY COST 90 PERCENT OF TOTAL • High Efficiency Motors • High Efficiency Pumps Generators • Correctly Sized to start second pump with all loads energized • Portable /Permanent • Transfer switches/ Manual or automatic • Fuels/ Diesel, Natural Gas, Propane, Gasoline. • Long Term maintenance cost PUMP STATION ELECTRICAL DESIGN 40 Years Lessons Learned Maynard Wayne Robertson, PE, CEM mwrobertson@vaughnmelton.com mwrdcr@comcast.net TAUD Technology Conference Gatlinburg, TN March 13, 2013