PPT

advertisement

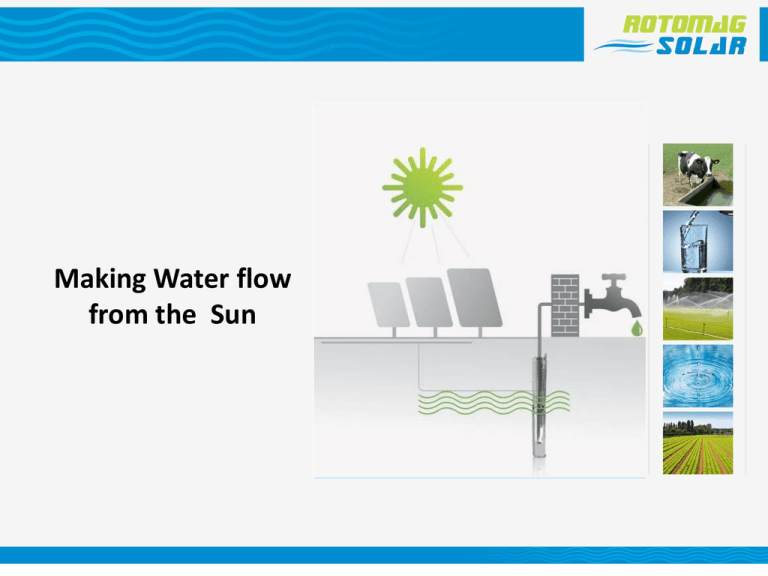

Making Water flow from the Sun ROTOSOL: Optimum Solar Pumping solutions by ROTOMAG The ROTOSOL Advantage 1. Technology : Ultra High efficiency BLDC & PMDC motors 1. Experience : 15 years in solar pumping 2. Capacity : 50,000 units of surface & submersible pumps/year 3. Support : 200+ Service Partners 4. Goal : High Quality Solar Pumping Installations Technology: Why BLDC is better ? Efficiency comparison of AC & DC motors Premium efficiency- Atleast 10% higher 92% 90% 88% 86% 84% 82% 80% 78% 76% 74% Eff2 Eff1 IE2 IE3 PMDC * AC motor efficiency is as per IS:12615 for 3 HP 4P motor BLDC Physical comparison of AC and DC pumps Leading AC Submersible 70% lower weight, 50% lower temperature, 300% higher weight to torque ratio Rotomag DC Submersible • Height : 1120 mm • Height : 740 mm • Total Weight : 52 Kgs • Total Weight : 18 Kgs • Difficult to handle • Easy to handle and install • Susceptible to damage • 300% higher torque to weight ratio • Efficiency : 81% (EFF2) • 96,000 LPD @ 30 M • Efficiency: 92% • 105,000 LPD @ 30 M Advantage of BLDC over AC Early Start • DC pumps use power directly from modules • Start at low irradiance levels • Inverting DC to AC causes losses • DC pumps start early and work till late Higher Starting Torque- reduced chances of clogging of pump in muddy/sandy water • Starting torque in AC motors is 2 times the rated torque • Starting torque in BLDC/PMDC is 5-6 times • AC pumps will stall in sandy/muddy water • DC pumps have sufficient reserve torque to clear the debris Advantages of BLDC Technology Fully encapsulated winding- cannot fail AC Motors • Exposed Windings • Sand and water ingress cause damage • Weak insulation causing drop in performance • Considerably reduced life Rotomag BLDC Motor • Totally Encapsulated windings • No effect of debris or water on winding • Consistent performance • Long life Sealed Rotor- Life time Guarantee. 200% higher torque for operation in sandy/muddy water AC Motor • Steel Laminations with AL rotor • Susceptible to oxidation due to moisture • Heavy construction • Higher moment of inertia • Late start early stop • Drop in performance over time Rotomag BLDC Motor • SS Shaft with rare earth magnets • No effect of moisture • Life long guarantee of performance • Lower weight – lower moment of inertia • Early start late stop Long Life Bearings. No replacement for 5 years AC Motor • Standard ball bearings used • No Dampening of axial thrust • Axial thrust causes damage • Reduced efficiency • Higher noise and vibration • Contamination due to debris • Reduced water discharge once damaged Rotomag BLDC Motor • Ceramic Carbon Thrust bearings used • Effective dampening of axial thrust • Lower noise and vibration • Increased efficiency • Higher resistance to contamination • Higher MTBF • Consistent performance Dedicated to Solar pumping for 15 years: How does it help ? Rotomag’s journey in solar pumping Vast exposure enables us to build different pumping solutions 1999 2007 2002 Development and installation of 1 HP Surface pumps 2011 Introduction of motors for export and JV for AC motors Installation of 2 HP Surface pumps 4500 Nos 2013 2014 BLDC pumps developed and approved by EQDC Development of BLDC submersible pumps begins 2000 Surface pumps and 250 Submersible pumps installed Designed for 10 years Top Quality SS components. Premium quality parts Example: Submersible pumps Range : 1 – 5 HP Head : 100 meters • High efficiency BLDC motor • Encapsulated winding with Thermal protection • SS 304 parts for long life and corrosion resistance • Laser welded impellers for high discharge • Thrust bearing ensures dampening of axial forces • Compact and light weight • Made in India – servicing and repairs possible Ability to withstand tough usage Designed for extreme conditions and user ignorance Example: BLDC controllers • IP 65 protection • Problem conditions shown with LED’s Sensorless dry running protection • 250C IGBT’s used as power stage • Overvoltage/Thermal overload protection • To be tested as per IEC 60068-2* Products suited for Rural India Fail proof, no electronics Example: Surface pumps Range : 1, 2 & 3 HP Head : 25 meters •Simple 2 wire design. No controller required • Easy to install and maintain • High Discharge suitable for flood irrigation • Designed for harsh Indian conditions • More than 5000 pumps installed till date Installations and End user training are the key Improper foundation Pump without foundation Poor Installation of pump Pump stuck in ground Capacity: Can we meet the market demand? Infrastructure Factory capacity: 50 K pumps per year Two plants: 1.6 lacs sq feet built up factory area Capacity : 28000 motors & 5000 pumps/month Semi Automatic production lines Sophisticated test equipment Manufacturing capability World Class processes Monthly Production Capacity : PMDC Motors AC motors & Geared motors Surface pumps Submersible pumps : 8,000 units : 20,000 units : 2,000 units : 3,000 units Inhouse R & D and quality assurance Pump testing set up Sophisticated testing facilities for Solar pumps Automatic testing and plotting of pump performance curves Solar PV simulator for automatic computation of water output/day Global reach of Rotomag products Quality validated by TOP European customers Banglades h, China, Srilanka, Yemen Germany, Switzerlan d,UK, Italy, Poland, Norway, NL Rotomag’s export markets Brazil, Columbia Over 70% of export revenue comes from Germany, Switzerland & USA USA, Mexico Canada Support: Being close to the users Training and Service support Professional and prompt after sales support • Total 200 Sales cum installation and service partners to be appointed • Regular training being provided to partners for quality installations • Standard work instructions and training manuals provided • Field service centers appointed to attend complaints in villages & towns • Master service centers appointed in major cities for repair / replacement of faulty parts • Inhouse dedicated team for audit and supervision of installations Sales Extensive and Service ServiceNetwork Coverage ‘Jalmitra’ sales cum support partners Support Partner Training Programme Equipping ‘Jalmitras’ to solve problems Regular training programmes being conducted to qualify ‘Jalmitras’. Installations: Precise, Standardized and built to last Standardised installation process Site Survey Material Supply System Installation Site Audit Training & Handover •Determine the source & depth of Water •Mark the location of PV Array •Calculate the water requirement and system suitability with micro irrigation system •Ensure that chosen pump and array combination is suitable for the site • Take site pictures for record • Schedule material supply based on the site availability • Ensure proper packing and send material to the site with appropriate checklist •Confirm material receipt at site and verify that all components are available • Schedule installation based on the availability of resources & site • Lay foundations and do the erection of structure as per WI • Take appropriate pictures during various stages of installation • Let the foundation cure for 3 days before mounting the PV modules • After 3 days, mount the modules and connect the array as per WI • Lower the pump in the bore and do the necessary connections as per WI •Check pump operation and ensure all the functions are operating normally •Check structure rigidity and alignment •Check the all the connections and ensure there are no open joints • Connect the pumping system to micro irrigation system and record the output • Incase of flood irrigation record water output by filling a standard container • Take site pictures for records •Conduct a training program for the beneficiary to explain the basic operation and features of the pumping system. •Explain the do’s and don’ts to ensure trouble free operation •Give information about warranty & service policy •Hand over the instruction manuals and details of local field service center •Complete the audit checklist and take final pictures of the site with the beneficiary High Quality Installations Starting point for a lifelong relationship long High Quality Installations Water that will change their lives