Value and Budget Housing Corporation: A Presentation by Mr. P S

advertisement

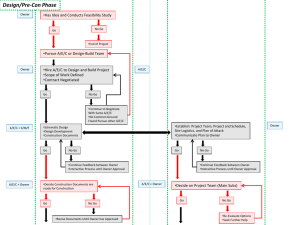

Value and Budget Housing Corporation Actual project picture Vaibhava Project Superior quality apartments, sale price from Rs.8 lakhs to Rs.20 lakhs Mission to build 1MN homes for low and moderate income households www.vbhc.com 2 Focus is exclusively on er Affordable Housing Size EMI or Rent EMS • 27 Sq.mt (290 sq.ft) of carpet area LIG • Between 28 sq.mt and 48 sqmt, Maximum of 516 sqft of carpet area MIG • • Between 49 sq.mt to 60 sq.mt Maximum of 645 sq.ft oc Carpet Area Not exceeding 30%40% of gross monthly income of buy of buyer *De4finition of the Ministry of Housing and Poverty Alleviation(2011) www.vbhc.com 3 Key tenets of Operations • Adopting manufacturing process as the key to address quality, timely delivery and cost effective solutions • Standardization of design, vendor development to get scale benefits • Sustainability solutions around water, waste, energy is critical for long term viability of the project • Customer research based decisions on project location, apartment and design of common facilities • Transparency in dealing with customers with full disclosure on specifications, delivery time line, cost and customer friendly documentation • Full compliance with regulatory environment www.vbhc.com 4 Standard catalogues/ prototype used in building designs Autodesk REVIT used to build standard components for modular buildings www.vbhc.com 5 Moulded Reusable Forms with flexibility on design www.vbhc.com 6 Standardization of Processes Method Statements What has been achieved • Breaking down each activity into its smallest element for superstructure, foundation and service buildings [ 85% of the value of Construction] • Standardization of processes, equipment, material resources for constructing prototypes • Making processes easy to replicate and monitor What is being done • Implementing training programs around standardized processes • Interlinking all elements in the BIM environment www.vbhc.com 7 Standardization of Equipment A. Formwork : Western Forms • • • • • • 1st Company to achieve casting frequency of 2 days Aluminum formwork has enabled us to introduce the concept of assembly line into the construction Mould assembly process is faster on account of light weight of the panels and the ease in setting up the mould Stricter control on internal dimensions because of tighter tolerances Easier to train workforce : Fresh workforce achieved baseline productivity in 90 days Lesser time to complete finishing Actual project picture We have been the pioneers in using premier Formwork in India. It has enabled us to meet our schedules and quality norms consistently www.vbhc.com 8 Sustainable model – VBHC Initiatives Water Management Extensive hydro-geological studies * Determine community size based on ground water availability * Treated water reuse via dual plumbing to each home * Low flow fixtures Sewage Treatment 100% on site sewage treatment using the Dewats technology *Treated water used for flushing, irrigation, washing, construction * Advantage of Dewats: a)Consumes 60% less electricity * Monthly maintenance cost for customers reduced by Rs 120 Energy Management Embedded energy and material use * Energy * Renewable energy on site * Savings - Common area lighting and street lighting load is 1 MW. Achieved 40% savings, energy efficient lifts save 8% www.vbhc.com 9 Sustainable model – VBHC Initiatives Solid Waste Management Ensures good sanitation, minimize disposal to land fill, reclaim energy and nutrients from waste * Helps in Source segregation, Biogas from organic waste, minimal disposal (< 15%) /Maximum recycling Food & Greenery Rooftop agriculture using controlled climate - commonly used vegetables, herbs and greens, pesticide free, drip irrigation to reduce water intake, thermal comfort for the top floor residents * Over 500 native species of trees are being planted in green www.vbhc.com 10 Thank You visit www.vbhc.com