Presentation - clean

advertisement

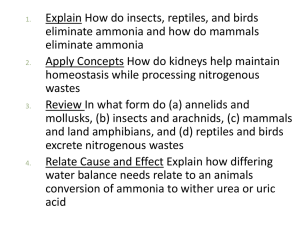

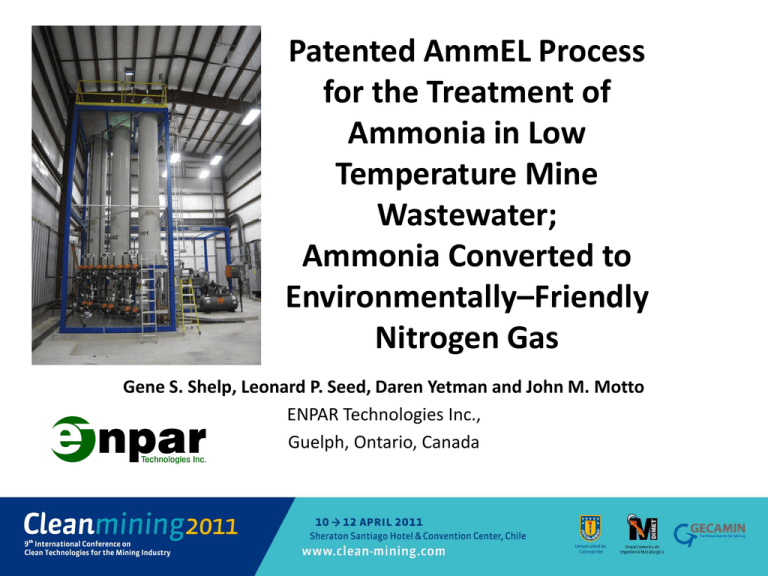

Patented AmmEL Process for the Treatment of Ammonia in Low Temperature Mine Wastewater; Ammonia Converted to Environmentally–Friendly Nitrogen Gas Gene S. Shelp, Leonard P. Seed, Daren Yetman and John M. Motto ENPAR Technologies Inc., Guelph, Ontario, Canada Introduction • Ammonia listed as a toxic substance by Environment Canada • One approach employed by the mining industry has been to lower the pH of the wastewater to render it less toxic (due to a shift in the NH3/NH4+ equilibrium) • While this approach has assisted in meeting acute lethality discharge requirements, the total ammonia-N released into the environment is not reduced • Current technology for treating ammonia relies heavily on biological activity (e.g. nitrification) to convert ammonia to nitrate Introduction • Total nitrogen removal requires additional biological processes to remove nitrate from wastewater prior to discharge • Biological treatment systems are adversely affected by cold temperatures and changes in effluent composition • A novel and patented ionexchange/electrochemical treatment technology (the AmmEL system) has been developed by Enpar Technologies, Inc. which is not adversely affected by low temperature The AmmEL Process Loading Regeneration Conversion (Phase 1) (Phase 2) (Phase 3) Treated Effluent NH4 IX Wastewater (NH4) IX NH4 Regenerant Tank N2 Electrochemical Reactor AmmEL Reactions 2NH4+ → N2 + 8H+ + 6e2Cl- → Cl2 + 2e- Cl2 + H2O → HOCl + HCl 2NH4+ + 3HOCl → N2 + 3H2O + 5H+ + 3Cl- The AmmEL Advantage • Eliminates nitrogen loading by converting ammonia directly into innocuous N2 • Does not produce nitrate and the GHG nitrous oxide associated with biological treatment • Not affected by low temperature • Intermittent operation -- no start-up delays • Can be fully automated -- low maintenance System Applications • Mining effluent or process streams containing ammonia derived from the use of ammonia based blasting powder and/or the oxidation of cyanide • Tertiary treatment for municipal waste water treatment plants (MWTP) and lagoon systems • Process streams related to steel, fertilizer and chemical industries Pilot Study The AmmEL-LC System AmmEL-LC Pilot Unit Specifications • 3-20 cm x 3.05m fluidized bed IX columns, BV = 59.3L • 1.5 kW electrochemical reactor • The main operating conditions for the system were as follows: – – – – Wastewater flow rate: 18-20 L/min Recharge brine flow rate: 8-10 L/min Brine NaCl concentration: 3-4% Cell current: 150 A • Designed to allow for single column operation as well as series column operation • Typical treatment mode was to operate the system with two columns in series in a lead-lag arrangement • Third column was either involved in a regeneration cycle or was in standby • Following a regeneration cycle, the regenerated column was rinsed with a small amount of treated water to remove any extraneous brine • The rinse stream was directed into a 200L holding tank for testing prior to release back into the holding pond IX 3 IX 2 IX 1 Reactor Single Column Results 99 98 97 100 96 92 30 Ammonia Concentration (mg/L) 27 28 28 29 90 32 31 88 29 31 86 31 30 84 29 79 27 30 28 80 75 25 90 70 67 58 20 60 53 50 14.2 15 40 11.6 9.6 10 6.5 5 0.3 0.5 0.8 1.2 2.2 2.7 3.7 4.5 30 7.6 20 5.1 10 0 0 1 2 3 4 5 6 7 8 9 10 11 12 Run Time (h) % Removed Inlet Ammonia Outlet Ammonia Breakthrough Curve at 18 L/min 13 14 Ammonia Removed (%) 35 Typical Single Column Results Flow rate (L/min) 18.0 Total run time (h) 14 Total volume treated (L) 15,120 Water temperature (°C) 5.7 Inlet pH 7.76 Outlet pH 7.85 Avg inlet ammonia (mg/L) 29.1 Avg outlet ammonia (mg/L) 5.1 Series Column Results 96 96 27 96 96 94 27 100 92 90 25 24 Ammonia Concentration (mg/L) 25 24 87 24 85 23 21 90 84 22 80 23 76 21 68 20 20 20 21 22 22 80 70 63 58 60 50 15 50 11.1 40 9.3 10 30 7.8 6.3 4.6 5 1.1 1.0 1.0 1.1 1.5 1.8 2.4 2.5 3.3 5.1 20 3.6 10 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Time (h) % Removed Inlet Ammonia Outlet Ammonia Breakthrough Curve, 18L/min, Columns C2 & C1 Ammonia Removed (%) 30 Series Column Results 99 99 99 32 98 32 97 32 96 32 30 94 33 91 32 88 30 30 32 90 100 33 32 32 32 87 30 90 82 Ammonia Concentration (mg/L) 78 25 80 72 24 66 70 60 20 50 15 40 10.8 30 8.7 10 7.3 20 5.7 5 0.1 0.3 0.4 0.6 0.9 1.3 1.9 2.8 3.5 3.2 4.2 10 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Time (h) % Removed Inlet Ammonia Outlet Ammonia Breakthrough Curve, 18L/min, Columns C1 & C3 Ammonia Removed (%) 35 Series Column Results Ammonia Concentration (mg/L) 35 96 97 96 95 35 35 94 35 100 37 91 37 90 35 37 37 35 85 34 32 37 32 82 79 90 82 76 30 80 73 70 25 60 20 50 40 15 10.0 10 6.5 5 1.1 1.1 1.4 1.7 2.2 3.2 3.7 7.7 30 8.4 6.8 20 5.0 10 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 Time (h) % Removed Inlet Ammonia Outlet Ammonia Breakthrough Curve, 18L/min, Columns C3 & C2 Ammonia Removed (%) 40 Series Column Results C2 & C1 C1 & C3 C3 & C2 Flow Rate (L/min) 18.2 18.1 18.3 Total Run Time (h) 16 15 13 Water Temperature (°C) 5.9 6.0 5.9 Inlet pH 7.79 7.84 7.82 Outlet pH 7.86 7.86 7.91 Average Inlet NH3 (mg/L) 23.0 31.0 35.3 Average Outlet NH3 (mg/L) 4.0 3.4 4.5 Pilot Study Conclusions • The AmmEL-LC system can readily remove ammonia from mine waste water to below the discharge requirement of 10 mg/L • No pretreatment of the stream was required • Operating costs were relatively low ($0.10/m3 of water treated) Full-Scale Installation • Full-scale installation commissioned March 10, 2010 in Timmins, Ontario • Three zeolite filled 30 cm (i.d.) x 6 m ion exchange columns • Electrochemical reactor → 18 m2 of anode surface area; 16V, 2000A DC rectifier • Chlorine gas scrubber to comply with Ontario MOE chlorine emission levels • The system is designed to treat 400 m3 of mine waste per day containing an average of 30 mg of ammonia-nitrogen/L • Average effluent levels are 10 mg NH3-N/L year round including during the winter months when mine water can reach temperatures slightly above freezing Ion Exchange Columns Electrochemical Reactor DC Rectifier Chlorine Gas Scrubber Ongoing Developments • New modified zeolite currently under development for use in IX columns – Selective in adsorption of ammonium ions vs. calcium and magnesium ions during effluent treatment – 6-fold decrease in transfer of calcium and magnesium to brine during recharge cycle – Pilot studies indicate instances of reactor cleaning and brine conditioning significantly reduced