Presentation

advertisement

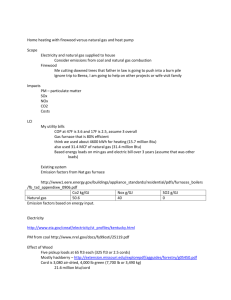

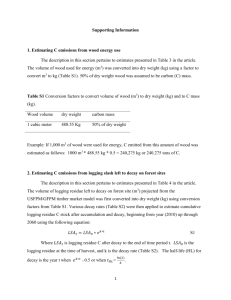

Example of Small LCA Project Steps of an LCA Life Cycle Assessment Framework Goal definition and scope Inventory analysis Impact assessment Interpretation Goal Definition and Scope • Evaluate burning firewood in residential application as a supplement to fossil • House is in Kentucky and current heating is with an air source heat pump and natural gas furnace • Determine impact of current fossil fuel consumption with supplemental wood heat Scope Continued • Consider impact of power plant and combustion of nat gas in house • Harvest and transport of firewood from Berea • Impacts considered – CO2 – NOx – SOx – Particulate matter (PM) – Costs Inventory Analysis - Procedure • Obtained previous years utility bills • Picked lowest month and used that bill as baseload electrical/gas consumption • Estimated fuel consumption for chainsaw and log splitter • Estimated quantity and energy value of firewood Existing Appliance Performance • Air source heat pump – COP at 47F is 3.6, COP at 17F is 2.5 – Assume average of 3.0 – Actually two heat pumps in house, assume both are same (similar performance) • Gas furnace is 80% AFUE • Use on a seasonal heating basis – 4600 kWh of electricity (15.7 million Btu) – 31.4 MCF (31.4 million Btu) • We need 76.2 GJ/heating season in the house Emissions from Fossil • Natural gas appliances in residential applications – DOE EERE (2008 standards) • Emissions from power plants DOE – EIA KY electric profile (2009) • PM from coal combustion NREL (1999) Wood Burning Characteristics • Energy content from University of MO for hackberry (21.6 million btu/cord) • Estimated 2.5 cords of firewood (5 pickup loads) • Emissions from fireplace – EPA certified stoves – 36,000 btu/hr output at 63% efficient – 4.42 g PM/hr • Other emissions (NOx and SOX) from 1999 EPA document (g/kg basis) Wood Harvest • EPA standards for SI gasoline engines under 18 hp (Federal Register for 2000) • Assume engines are 33% efficient – no reference • Emissions listed for – CO (assume all goes to CO2) – HC+NOx (from EPA, 2/3 of this category would go to PM, assume this is true, based on cars) – Gasoline 340 ppm sulfur – assume goes to 2.78 g SO2/gallon Results – Impact Assessment • Emission factors (fossil and wood burning) • Total emissions for house (fossil and wood burning) Results – Emission Factors Emission Factor (g/GJ or kg/GJ) 3500 3000 2500 CO2 (kg/GJ) NOx (g/GJ) SOx (g/GJ) PM (g/GJ) 2000 1500 1000 500 0 Natural gas Considers upstream emissions Electricity Wood Results – Emissions from Original Emissions in a Heating Season (kg or g) 60000 50000 CO2 (kg) NOx (g) SOx (g) PM (g) 40000 30000 20000 10000 0 Natural gas Electricity Total Results – Emissions with Stove Emissions in Heating Season (kg or g) 60000 50000 40000 CO2 (kg) NOx (g) SOx (g) PM (g) 30000 20000 10000 0 Natural gas Electricity Wood Total Results Net Changes Reduction Using Wood Stove (%) 40 20 0 -20 CO2 NOx SOx PM -40 -60 Reduction Interpretation - Existing • Air source heat pump reduces impact due to COP – Use half the energy of natural gas – Get over 2/3 of useful heat from electricity • Natural gas high NOx emissions • Coal has high CO2, SOx, and PM Interpretation - Wood • 45% reduction in fossil energy • Assumed evenly split between gas/electric • Significant reduction in CO2 and SOx relative to base case • PM slightly lower than base • NOx increased relative to base case – Small SI engines big part of NOx emissions Impact of Various Stages CO2 kg NOx g SOx g PM g Gas comb. 926 732 - - Gas upstream 100 2,800 - - Gas subtotal 1,026 3,532 - - Coal comb. 2,391 2,053 6,506 22,812 381 266 4,562 Coal upstream 61 Coal subtotal 2,452 2,434 6,772 27,375 Wood comb. 0 3,490 698 7,956 Wood upstream 193 4,421 56 5,922 Wood subtotal 193 7,911 754 13,878 13,877 7,527 41,253 System total 3,670 Summary of Impacts Life Cycle Costing • $661/yr in heating for fossil case • With wood stove increases to $759/yr – Due to cap cost of stove (~400/yr) • Would take a 40% increase in electric and nat. gas cost to be equal • No value on time handling firewood Potential Problems • Uncertainty in electricity used for heating – based on lowest electric bill • Assumed a SI engine efficiency • Assumed conversion of HC to PM – Other conversions from g C to g CO2 and g S to g SO2 • Splitting of energy reduction – assumed equal gas and electric Other Potential Problems • Wife not happy with me gutting the fireplace and redoing it according to manufacturer’s specs • Estimates on fuel consumption during wood cutting • Happy cat though