HSE-MS Implementation

advertisement

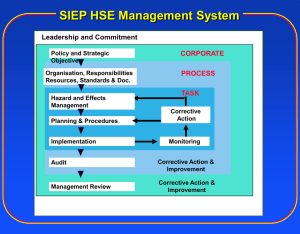

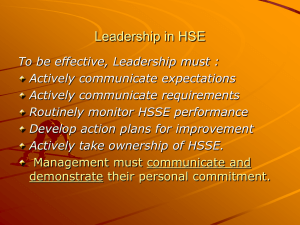

HSE for Supervisors HEMP Module Version two 2007 1 Module Administration Emergency procedures Facilities: first aid, prayers, refreshments and toilets Documentation: class roster and HSE passports Restrictions: smoking, telephones and pagers Introductions: name, company, position and expectations of the module Version two 2007 2 Module Aims Aims of the module are to provide supervisory staff with an awareness of their HSE responsibilities in respect of PDO HSE management system and the application of the hazards and effects management process (HEMP) Version two 2007 3 Module Objectives On completion of module attendees will be able to: explain the basic structure of the PDO HSE management system describe the HEMP model and application in the PDO workplace explain the term ‘as low as reasonably practicable’ (ALARP) describe principles of completing an HSE safety case explain the concept of ‘bow tie’ diagrams Version two 2007 4 Module Objectives (continued) and describe the process of applying control measures explain the hierarchy of controls describe the process of determining recovery measures for identified hazards in a simulated workplace activity describe the PDO risk matrix and use to classify typical workplace hazards carry out the HEMP process on a simulated workplace activity and produce a simple ‘bow-tie’ diagram to illustrate how the hazard has been assessed and will be controlled Version two 2007 5 PDO-HSE Management System PDO-HSE-Management System (HSE-MS): managing HS & E hazards and effects in a structured way Is a systematic process of risk identification, assessment, control and recovery sets performance standards for managing HSE assesses and continuously improves performance, monitoring, audit and review Version two 2007 6 HSE-MS Elements HSE-MS elements : leadership and commitment policy and strategic objectives organisation, responsibilities, resources, standards and documents hazards and effects management planning and procedures implementation and monitoring audit review Version two 2007 7 Leadership and Commitment Leadership and commitment requires: top down commitment effective management a cohesive culture visible leadership clear statement of targets informed involvement allocation of appropriate resources Version two 2007 8 Leadership and Commitment Policy & strategic objectives Organisational, responsibilities, Resources, standards & documents Hazards & effects management Corrective action Planning & procedures Implementation Monitoring Audit Management review Version two 2007 9 PDO - HSE Policy PDO-HSE policy: management approved systematic approach to managing HSE compliant with Omani law, ministerial decisions, licences, permits and approvals compliant with ISO 14001 approved environmental management systems compliant with Shell global HSE management system and policies Version two 2007 10 PDO - HSE Strategic Objectives PDO-HSE strategic objectives: mission, vision and policy statements statement of business principles and objectives social responsibility and sustainable development managing risk, people, organisation, business processes and assets optimum performance Version two 2007 11 Organisation, Responsibilities, Resources, Standards and Documents HSE-MS requires: everyone to be responsible for HSE performance appropriate organisational structure appropriate & adequate human, physical and financial resources clear communication of HSE requirements & standards cohesive documentation, planning, scheduling, implementation and maintenance of management system competent and trained employees Version two 2007 12 Hazards and Effects Management Process HEMP provides a structured approach to: identifying hazards assessing related risk applying appropriate control measures, and prescribing appropriate recovery measures if controls fail Version two 2007 13 HEMP Identify hazards Assess related risk Prescribe recovery measures Apply control measures Version two 2007 14 HSE-MS & HEMP HSE MS elements Hazard & effect management Identify hazards Assess risks Control measures Version two 2007 Recovery measures 15 HEMP & HSE Case Introduction Description Summary HEMP HSE Critical Tasks Identified shortfalls & remedial Conclusions & statement of fitness Executive summary HSE Case Version two 2007 16 HSE Case HSE Case: combines information from hazards and effects register identifies hazard effects and threats assesses likelihood and consequences of a hazardous event manages potential causes by detailing control measures mitigates potential consequences with recovery measures demonstrates how risks are managed to ALARP Version two 2007 17 Identifying Hazards and Effects Identified and assessed by: experience and judgement checklists codes and standards structured reviews techniques Version two 2007 18 Determining Risk Factors in determining risk: complexity of facilities, activities, products and services routine, non-routine and emergency activities supervision, communication and worker competence detriment to workforce, public and the environment climatic and other variable operating conditions effectiveness of control barriers Version two 2007 19 Risk Assessment Risk to: people asset environment reputation Assessed by severity and likelihood Version two 2007 20 Risk Severity Severity ratings: none slight minor major national international Version two 2007 21 Likelihood of Risk Occurring Increasing likelihood: never heard of in industry heard of in industry incident has occurred in PDO happens several times per year in PDO happens several times per year in a location Version two 2007 22 Severity Rating Assessment Likelihood Severity Consequences People Assets Environment Reputation 0 No health effect/injury No damage No effect No impact 1 Slight health effect/injury Slight injury Slight effect Slight impact 2 Minor health effect/injury Minor damage Minor effect Limited Impact 3 Major health effect/injury Localised damage Localised effect Considerable impact 4 Permanent total disability or 1 fatality Major damage Major effect National impact Multiple fatalities Extensive damage Massive effect International Impact 5 A Never heard of in industry Version two 2007 B Heard of in E&P industry C Incident occurred in PDO D Occurs several times per year in PDO E Occurs several times per year in location Low Risk Medium Risk High Risk 23 Control Measures Control measures: preventative measures to reduce likelihood of risk occurring mitigatory measures to reduce consequences recovery measures to reduce chain of consequences arising from risk event Version two 2007 24 Hierarchy of Controls Control hierarchy: elimination substitution engineering controls administration safe procedures training PPE Version two 2007 25 ALARP As low as is reasonably practicable (ALARP): risk is reduced to a level of ALARP, at a point in time in relation to the difficulty and cost in achieving a commensurate level of risk reduction Version two 2007 26 ALARP Version two 2007 27 Exercise One Working in teams attendees will consider a scenario and: identify the potential hazard assess the associated risk decide appropriate control measures prescribe recovery measures Version two 2007 28 Control Barriers Control barriers Hazard Supervision barrier Communication barrier Competence barrier Version two 2007 Adverse incidents & accidents 29 HEMP Control Tools Control tools: Fault tree analysis Event tree analysis Bow-tie diagram Version two 2007 30 Bow-tie Diagram Version two 2007 31 Threats Potential causes to release a hazard and produce an incident: thermal chemical biological radiation condition uncertainty human factors Version two 2007 32 Incidents Incidents are: release or near release of a hazard exceeding defined limits unplanned events or chain of events which has or could have caused injury, illness, damage and loss to asset, environment or third parties Version two 2007 33 HEMP Recovery Measures aimed at reinstating or returning situation to normal operating conditions Version two 2007 34 HEMP Records Hazards and effects register: demonstrates all hazards and effects have been identified, understood and properly controlled kept current for life cycle of project from design through operation to decommissioning Version two 2007 35 Planning and Procedures Management of HSE risk: planning procedure objective target Version two 2007 36 HSE-MS Implementation Ensuring HSE-MS is applied: set performance measures and indicators establish monitoring to measure performance address non-compliance and apply corrective action ensure incidents are notified, analysed, reported, followed-up and closed out Version two 2007 37 HSE-MS Monitoring Activity monitoring to ensure implementation: pro-active monitoring reactive monitoring Version two 2007 38 HSE-MS Audits HSE-MS audits: determine HSE-MS elements are implemented determine HSE-MS fulfils policies, objectives and performance criteria determines HSE-MS complies with legislation and regulations identify areas for improving HSE-MS enable management to address HSE-MS issues of concern Version two 2007 39 HSE-MS Review Senior management review HSE-MS to: manage HSE risks reinforce continual HSE performance improvement ensure continued suitability and effectiveness address need for change and continual improvement allocate resource for implementation and maintenance evaluate sites or situations hazards and risks and emergency planning, and document HSE-MS processes, performance, results and recommendations Version two 2007 40 Exercise Two Working in teams attendees will consider a scenario and produce a bow-tie diagram Version two 2007 41