Lecture series 6 - Civil and Environmental Engineering | SIU

advertisement

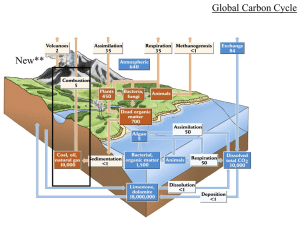

CE 510 Hazardous Waste Engineering Department of Civil Engineering Southern Illinois University Carbondale Instructors: Jemil Yesuf Dr. L.R. Chevalier Lecture Series 6: Volatilization Course Goals Review the history and impact of environmental laws in the United States Understand the terminology, nomenclature, and significance of properties of hazardous wastes and hazardous materials Develop strategies to find information of nomenclature, transport and behavior, and toxicity for hazardous compounds Elucidate procedures for describing, assessing, and sampling hazardous wastes at industrial facilities and contaminated sites Predict the behavior of hazardous chemicals in surface impoundments, soils, groundwater and treatment systems Assess the toxicity and risk associated with exposure to hazardous chemicals Apply scientific principles and process designs of hazardous wastes management, remediation and treatment Volatilization Evaporation of solid or liquid into the gaseous phase Air emissions from hazardous management facilities regulated under Clean Air Act. May be considered Hazardous Air Pollutants (HAP) Engineered Systems: Air Stripping Diagram of an air stripping tower. Water is piped into the top, and pours over the packing. A Counter current of air is blown into the bottom of the tower, and blows by the water, removing the contamination. vent contaminated water in packing material packing support clean water out clean air in air blower Packing media: new and after four years Source Engineered Systems: Soil Vapor Extraction vent to atmosphere air vent or injection well vapor treatment C.F. LNAPL LNAPL water table residual NAPL impermeable boundary saturated unsaturated surface soil cap vacuum A typical vapor phase GAC system. The grey cylinder on the right is an air/water separator. This unit is necessary to keep water from fouling the GAC vessels. Water removed from the soil gas is stored in the black tank on the right. The two white cylinders contain the GAC, which adsorbs organic contaminants from the soil gas. The grey unit on the left contains the blower that pulls the soil gas from the wells and through the vessels. Source Approach Volatilization from Open Containers Volatilization from Surface Soils First we need to review the definition of vapor pressure and Henry’s Law Volatilization from Deep Soil Contamination Vapor Pressure Range @ 20 C 10-10 mm Hg 760 mm Hg T VP The temperature that causes the vapor pressure to reach 760 mm Hg is the boiling point of the compound. See Appendix J p. 705 Table 6.1 p. 309 Higher driving force Class Problem Determine the vapor pressure for anthracene and carbon tetrachloride. Which is more volatile? Henry’s Law For a closed system Equilibrium between gaseous and aqueous phase Dilute contaminant P HX P= partial pressure (atm) H = Henry’s Law const. (atm-m3/mole) X = concentration (mole/m3) H<10-7 atm-m3/mole less volatile than water, conc. will increase. H>10-3 atm-m3/mole volatilization is rapid Henry’s Law VP H S Henry’s Law constant may also be considered a partition coefficient between air and water, analogous to the octanol-water partition coefficient Here, S is water solubility High water solubilities and low vapor pressure tend to decrease the potential for volatilization of dilute species Henry’s Law B Correction for temperature H exp A See values Table 6.2 p. 310 T H - Dimensionless quantity that may be H ' used in design RT - the ratio of the mass of compound in the vapor phase to the mass of compound in the aqueous phase. Class Problem Estimate Henry’s Law constant for benzene at 30C. Governing Equation B H exp A T Solution From Table 6.2, A = 5.53 and B = 3190. B H exp A T 3190 exp 5.53 0.0068 303 compare to H = 0.0055 at 25 C Class Problem Experimental determination and application of Henry’s constant Air is comprised by 21% oxygen on a molar basis. If we bubble a large amount of air through a liter of water until it is saturated with the air, the amount of oxygen in the water at this condition of equilibrium is dictated by Henry’s law. If the amount of oxygen is measured using a DO probe and is 9.3 mg/L, a) Calculate Henry’s law constant b) Determine how much oxygen will be dissolved in water at 20 ºC if pure oxygen (PO2 = 1 atm) is bubbled through the water until it is saturated. Density of air at 20 ºC = 1.2 g/L Density of water at 20 ºC = 998 g/L Solution a) Mass ratio of oxygen in the water: = 9.3 mg/L X 0.001 g/mg X 1L/998 g = 9.3x10-6 g-O2/g-water Mass ratio of oxygen in the air: Remember that 1 mole of any gas occupies 24.05 L of volume at 1 atm. pressure and 20ºC (Ideal Gas Law) and density of air is 1.2 g/L, Number of moles of oxygen in 1 L of air is: = 0.21 X (1/24.05) moles = 0.0087 moles Mass ratio of oxygen in the air ( 1 liter basis) is then calculated as: = (0.0087 moles X 32 g/mole)/(1.2 g) = 0.233 g-O2/g-air Solution Henry’s constant in non-dimensional form (H’) is then: = (0.233 g-O2/g-air)/ 9.3x10-6 g-O2/g-water Converting g-air and g-water into volume basis, multiplying the above expression by, (1.2x103 g/m3)/(0.998x106 g/m3) H’ = 30.12 (mol O2/m3-air)/(mol O2/m3-water) And from H’ = H/RT, H = H’RT = 30.12 x 8.21x10-5 x 293 = 0.725 atm-m3/mol Solution b) From Henry’s law equation: PO2= H.X, And for pure oxygen, PO2 = 1 atm; thus X = PO2 /H = 1 atm/(0.725 atm-m3/mol) = 1.38 mol/m3 = 44.1 g/m3 = 44.1 mg/L ......end of example Estimation of Flux from an Open Container Q VP P This term represents the driving force Q is the evaporation rate (mass/time) VP is the vapor pressure (atm) P is the partial pressure of the compound above the liquid If open, P = 0 Estimation of Flux from an Open Container MKA VP P Q RT where Q = mass flux (evaporation rate) M = molecular weight K = mass transfer coefficient per area Estimation of Flux from an Open Container The mass transfer coefficient K can be estimated using water as a reference Kw = 0. 83 cm/s Molecular weight of water = 18 g/m M2 K1 K 2 M1 1 3 18 0.83 M1 1 3 Class Problem A container of benzene has been left open. Estimate the rate of volatilization across the surface of the container. The dimensions of the container are 1.25m x 0.75m x 0.3 m deep. The temperature is 20C. Approach Governing Equation MKA VP P Q RT M2 K1 K 2 M1 1 3 18 0.83 M1 1 3 Solution 1. Need to solve for K. 2. Molecular weight of benzene is 6(12)+6 = 78 g/mol M2 K1 K 2 M1 1 18 0.83 78 3 1 3 18 0.83 M1 .509cm s 1 3 Solution 3. Area = 1.25 m x 0.75 m = 0.94 m2 4. Vapor pressure = 76 mm Hg = 0.1 atm MKAVP P Q RT 78 g mol 0.00509m s 0.94m3 0.1 atm 0 3 m atm 8.21105 293 K m ol K 1.55 g s Compare to Ex. 6.1 p. 313 Saturation in an Enclosed Area Spills in • waste transfer areas • drum storage areas Need to assess the saturated vapor concentration in order to assess toxicity or explosivity of the vapor Factors to consider: volume of enclosed space ventilation rate contaminant flow rate out of enclosed space contaminant volatilization rate Saturation in an Enclosed Area C ppm Qm RT 6 10 kQv PM where Qm = volatilization rate of the compound [M/T] (g/s) Qv = ventilation rate of the enclosed area [M/T] (m3/s) k = factor for incomplete mixing (0.1-0.5) M = molecular weight (g/mol) Class A container of benzene has been left open in a warehouse. The dimensions of the container are 1.25 m x 0.75 m x 0.3 m deep. The temperature is 20C and pressure is 0.1 atm. The facility is 220 m3 in volume. Ventilation is 12 changes of air per hour. Using k=0.2, determine the steady state benzene concentration in the warehouse. Governing Equation MKA VP P Q Qm RT C ppm Qm RT 6 10 kQv PM Solution 1. From previous problem Qm = 1.55 g/s 2. Calculate the ventilation rate Qv = (12 changes of air/hr)(220 m3/change)(1 hr/3600 sec) = 0.73 m3/s Solution Continued 3. Determine the steady-state benzene concentration C ppm Qm RT 106 kQv PM 1.55 s 8.2110 293 K 6 10 0.20.73m sec 0.1 atm78 g mol 5 g 3 3274ppm m3 atmmol K Volatilization from Soils Soil particles air diffusion water Sorption/desorption Volatilization from Soils Soil particles diffusion air sorption water dC C dt dC kC dt Ct t dC k dt 0 C Co Ct C o e kt Volatilization from Soils Soil particles diffusion air water sorption VP kv 4.4 10 K oc S 7 DOW researchers determined an empirical relationship for a first-order decay rate for contaminant loss from a surface spill, kv where VP = vapor pressure (mm Hg) Koc = soil adsorption coeff. (mL/g) S = solubility (mg/L) Example A carrier has spilled lindane on soil. Estimate the time required for 70% volatilization. Governing Equations VP kv 4.4 10 K oc S 7 Ct Co e kt Solution From reference tables in the appendix S = 7.3 mg/L Koc = 1995 mL/g VP = 9.4 x 10-6 mm Hg VP kv 4.4 10 K oc S 7 6 9 . 4 10 kv 4.4 107 0.028 day1 19957.3 Solution Ct Co e kt Ct 0.028 t 0 .3 e Co t 43 days Volatilization in Deep Soils More complex Models are mostly specific to matrix Hamaker Equation one of the better generalized models and assumes that the contaminant zone is semi-infinite i.e. the contaminant zone extend into the aquifer and the source is large Volatilization in deep soils Qt 2Co D1 D2 M2 M1 Dt Qt = volatilization of compound per unit surface area (g/cm2) Co = initial concentration (g/cm3) D = diffusion coefficient of vapor through coils (cm2/s) t = time (sec) Very few data are available for diffusion coefficients. This equation allows a prediction of D based on the known value of 0.01 cm2/s for ethylene dibromide and 0.042 cm2/s for ethanol. Problem Estimate the flux of benzene from a deeply contaminated soil over 1 day with a concentration of 500 ppm and a bulk density of 1.50 g/cm3. Data and Governing Equations MW Benzene 78 g/mol MW Ethanol 46 g/mol MW Ethylene dibromide 188 g/mol D for ethanol 0.042 cm2/s D for ethylene dibromide 0.01 cm2/s Qt 2Co D1 D2 M2 M1 Dt Solution 1. Determine D using both equations and take the average D1 46 0.032 0.042 78 D1 188 0.016 0.01 78 Daverage = 0.024 cm2/s Solution 2. Convert 500 ppm benzene to g/cm3 mg kg mg g 500 0.0005 kg g 500ppm 500 g g g 0.0005 1.5 3 0.00075 3 Co g cm cm Solution 3. Determine Q Qt 2Co Dt 20.00075g cm3 0.038 g cm3 0.024 86400s cm2 s Summary of Important Points and Concepts The two most important parameters for assessing volatilization are vapor pressure and Henry’s Law constant Vapor pressure of hazardous waste range from essentially nonvolatile to those that rapidly evaporate Henry’s Law constant is a useful predictor of volatilization from water Henry’s Law constant is analogous to the octanol-water partition Summary of Important Points and Concepts Vapor pressure and the mass transfer coefficient K are needed to determine the flux across an open container For enclosed areas, an equation based on mass balance can be used to determine the concentration of contaminant in the air Equations for determining the volatilization for soils are more complex because of variability in characteristics (e.g. sorption, water content, diffusion) Summary of Important Points and Concepts Researchers at Dow developed an empirical equation for estimating the first order decay rate for surface soils Hamaker’s equation works reasonable well for a range of problems involving the volatilization of contaminants in deep aquifers