Hoshin Kanri

Lean Enterprise Series

© 2009 Factory Strategies Group LLC. All rights reserved.

Outline

1.

2.

3.

4.

5.

Definition of Hoshin Kanri

History of Hoshin Kanri

Introduction to Hoshin Kanri

Implementing Hoshin Kanri

Summary

© 2009 Factory Strategies Group LLC. All rights reserved.

2

Hoshin Kanri

Hoshin Kanri is a step-by-step planning,

implementation and review process for managed

change. It is a systems approach to the

management of change in critical business

processes.

Hoshin Kanri is a proven technique that helps

organizations focus efforts and achieve results.

© 2009 Factory Strategies Group LLC. All rights reserved.

3

History of Hoshin Kanri

• After World War 11, Japan was faced with the difficult

task of rebuilding its economy and infrastructure

without out allowing the military to be rebuilt.

• Hoshin Kanri is a planning process that was developed

in Japan but it is based on the US techniques of

Management by Objectives and the classical Plan-DoCheck-Act (PDCA) improvement cycle.

• Hoshin Kanri is used to communicate company policy to

everyone in the organization

• Its primary benefit is to focus activity on the key things

necessary for successes.

• Japanese Deming Prize winners credit Hoshin as being a

key contributor to their business success.

© 2009 Factory Strategies Group LLC. All rights reserved.

4

Introduction: Process

Top Management sets the

overall vision and the annual

high-level policies and targets

Each level pass on

targets to the next

level.

Each level under top management

is, in turn, involved with the level

above it to make sure that its

proposed strategy corresponds to

requirements.

At each level down,

managers and employees

participate in the

definition, from the overall

vision and their annual

targets, of the strategy and

detailed action plan

© 2009 Factory Strategies Group LLC. All rights reserved.

Regular reviews take place to

identify progress and problems, and

to initiate corrective action.

5

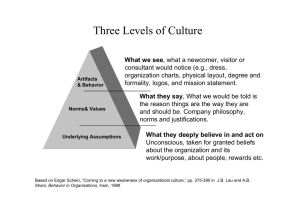

Critical Behaviors

Leadership must take steps to close the gap between

today’s performance and an organization’s vision.

• People seem to need either a crisis or goals to achieve

extraordinary outcomes.

• Research shows that performance-focused management

practices can increase performance by at least 30-40%*

• Hoshin combines long and short-term planning methods

with quality and objective management methods to

produce a plan-to-do-act cycle.

© 2009 Factory Strategies Group LLC. All rights reserved.

*Julia Graham: “Developing a Performance-based Culture” – The Journal for Quality and Participation, 2004

6

Fundamental Systems

There are two management systems fundamental

to Hoshin: daily and cross-functional management

systems.

Daily Management System

Cross-Functional Management System

• deals with the operation and

monitoring of micro work processes

• supports identification of task level

work, creation and improvement of

task level work processes,

• supports subject matter experts

• provides communication to

management and cross functional

work team

• encourages participation and

involvement

• The improvement of processes

spanning the entire organization

• Addressing issues such as product

or service quality

• Lean Six Sigma is one example

• Critical to the management of an

organization’s vision and mission,

identification and management of

cross-functional work processes,

and issues and cross-functional

work process improvements

© 2009 Factory Strategies Group LLC. All rights reserved.

7

Breakthrough Performance Plans

Annual Plan

• The gap between the long-range plan and business

fundamentals plan provides motivation for change

• The long-range plan is the basis for the annual plan

which identifies what must be accomplished this year

to move the organization along the path to the future

as specified in the long-range plan

• It is very detailed and lays the foundation for what

must be accomplished in the way of improvement

(change) and how success will be measured

• Unlike the long-range plan, the annual plan likely will

change significantly year to year

© 2009 Factory Strategies Group LLC. All rights reserved.

8