Hot Work (Employee). - Lumbermen`s Underwriting Alliance

advertisement

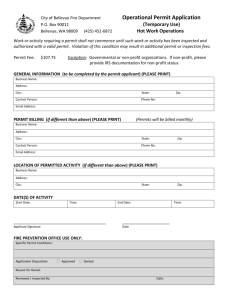

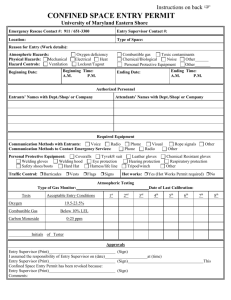

Lumbermen’s Underwriting Alliance Hot Work Program Employee Presentation Loss Prevention Services - Rev April 14, 2011 This presentation is intended to provide employees with a general overview of safety measures in connection with hot work operations. It covers the safe work techniques to be followed by employees and contractors in order to prevent hazards associated with hot works. References used Fire Protection Association (FPA) National Fire Protection Association (NFPA) American National Standards Institute (ANSI) National Fire Code Of Canada 2005 Objectives Definition of hot work. Hot work safety requirements. Company Hot Work Program. The hot work permit. Hot work permit decision process. Spark watcher decision making. Employee training requirements. Contractor safety requirements. Hot work losses. Questions. Definition of hot work Hot Work is any work using open flames or sources of heat that could ignite materials in the work area. Examples of hot work are: welding burning brazing propane soldering oxyacetylene cutting grinding ferrous metals Definition Hot Work “designated area”: A permanent location designed or approved for hot work operations. This location shall be a specific area approved for the performance of hot work, such as a maintenance shop or a detached outside location of incombustible or fire-resistive construction and essentially free of combustible and flammable contents. Hot Work Safety Concerns Workers exposed by hot work hazards. Numerous workers are critically injured each year from hot work accidents. Dangerous fires occur annually from hot work causing millions of dollars in loss. Proper training can significantly improve hot work safety awareness. Company Hot Work Program A company Hot Work Program shall include the following: A documented company policy The use of hot work permits Training of all employees A contractor policy Ongoing review of the hot work program Hot Work Permit Hot Work Permits are required for any temporary operation involving open flames or producing heat and/or sparks. This includes, but is not limited to: Brazing, Cutting, Grinding, Soldering, Thawing of pipes, Torch Applied Roofing and Welding. Hot Work Permit The Hot Work Permit is divided into two parts: Part 1 is the white cover sheet Part 2 is the orange copy. Hot Work Permit - Part 1 On the left side of the permit, you find the following: Fire Safety Supervisor Instructions Employee performing Hot Work Location/building Authorization to perform hot work Hot Work Permit - Part 1 On the right side of the permit, you find the following: Actions to be taken: BEFORE HOT WORK DURING HOT WORK AFTER HOT WORK OTHER PRECAUTIONS TAKEN Hot Work Permit - Part 1 BEFORE HOT WORK Sprinklers, hose streams and extinguishers in service. Hot work equipment in good condition. Floors swept and work area clear of all combustibles within a radius of 35 feet (11m). Combustibles that cannot be moved are covered with fire retardant tarpaulins or shielded by non-combustible materials. Combustibles on other side of walls, ceiling or roofs are cleared away. Conveyors and suction systems in the area are shut down. All wall floor openings shielded. Fire resistive tarpaulins suspended beneath overhead work. Area wet down except when arc welding. Containers purged of flammable liquids/vapors. Pressurized vessels, piping and equipment removed from service, isolated and vented. Anything that can burn must be removed from the immediate work area. Hot Work Permit - Part 1 DURING HOT WORK Post Permit. Trained spark watcher(s) stationed on site, in adjacent areas and on lower levels with fire fighting equipment during hot work. Hot Work Permit - Part 1 AFTER HOT WORK Area thoroughly wet down. Exposed lower level(s) thoroughly wet down. Post guard to patrol hot work area for a minimum of 60 minutes on a continual basis after job is completed. If applicable, notify watchman of location where hot work was done as well as exposed lower level(s). Keep permit posted where work was performed. Equipment stored properly. OTHER PRECAUTIONS TAKEN Monitor hot work area for a minimum of 5 hours Hot Work Permit - Part 2 In addition to Part 1, you have the following: Spark Watcher Signature, and Final Check-up Hot Work Permit Decision Process NFPA 51B Figure A.5.4 Spark Watcher Decision-Making PAI= Person Authorizing Hot work. AHJ= Management NFPA 51B Figure A.5.5.1 Multiple Spark Watchers Needed NFPA 51B Figure A.5.5.1(1)(b) Employee Training Requirements All supervisors and employees are to be trained before being involved in, or conducting Hot Work. They are to be trained on their Company Hot Work program which includes the following: Understand the Company policy Understand the use of the Hot Work Permit Understand the contractor policy Contractor Safety Requirements Before starting any hot work, contractors and their clients shall discuss the planned project entirely, including the type of hot work to be conducted and the hazards in the area. Management should ensure that the contractor has evidence of financial responsibility, which can take the form of an insurance certificate or other document attesting to coverage or responsibility. A contractor may have the technical expertise to perform hot work but is not likely to have a full understanding of fire prevention or of the specific combustible hazards within a client property. Additional safeguards to be considered include, but are not be limited to: how the hot work should be isolated to prevent fire hazards; who will be assigned as the spark watcher for the hot work operations; the facility emergency notification procedures; available manual fire fighting tools (like portable fire extinguishers and small hose stations); identification of all areas where hot work is not allowed; connecting hot work equipment to existing utility systems (gas or electricity); and review of any requirements for completion of hot work by a certain time each day. Contractor Safety Requirements Hot work loss incidents involving contractors occur with regular frequency. For many of these incidents, facility management did not implement a process for managing the fire hazards associated with the proposed contract work activity. Some view the contractor's personnel as recognized subject matter experts, and are either ignorant of potential fire hazards with the planned activity. Do not make assumptions about contractor’s knowledge of or practice of safe hot work procedures. Always confirm. Hot Work Fire January 13, 2005 ($1,385,000) Hot Work Fire March 27, 2006 ($3,730,000) Hot Work Fire March 28, 2006 ($3,730,000) Hot Work Fire August 8, 2006 Hot Work Fire May 21, 2008 ($ 6,500,000) Hot Work Fire January 26, 2007 ($200,000) Hot Work Fire March 8, 2007 ($7,000,000) Hot Work Fire November 9, 2008 ($3,500,000) Hot Work Fire January 1, 2009 ($9,000,000) Hot Work material available QUESTIONS ?