Module 5b

advertisement

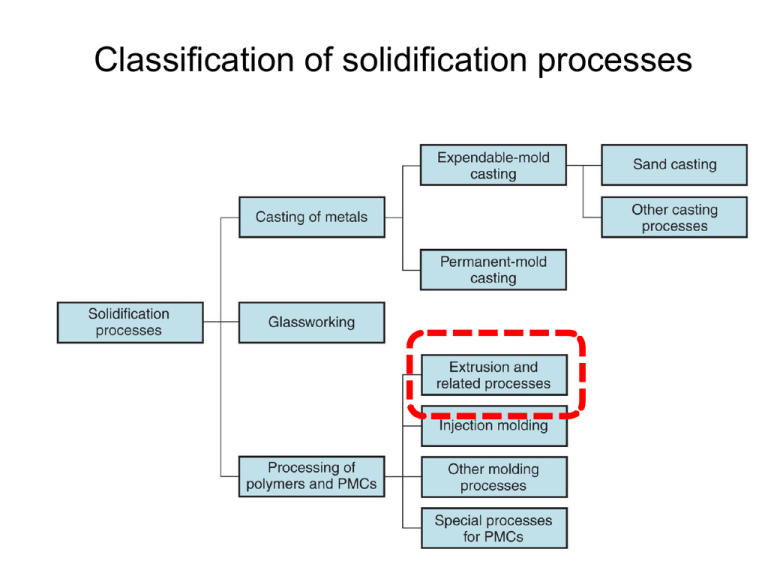

Classification of solidification processes Principle of the process Structure/Configuration Process modeling Defects/quality control Design For Manufacturing (DFM) Process variation 2 Shaping Processes For Plastics - Extrusion 1. Introduction Screen pack 3 Shaping Processes For Plastics - Extrusion 1. Introduction Extrusion is a process in which the material is forced to flow through a die orifice to provide a long, continuous product whose cross-sectional shape is determined by the shape of the orifice 4 Shaping Processes For Plastics - Extrusion 2. Analysis of Flow Rate 5 Shaping Processes For Plastics - Extrusion Find the flow rate with respect to various parameters in the system. These parameters include: parameters of the screw, the clearance between the screw and the inner surface of the barrel. 6 The goal of the engineering analysis: 1. The flow rate or production rate. 2. The pressure of the or product 7 The general idea to meet the goal: 1. Flow rate inside the extruder and at the die ? 2. Flow rate outside the extruder and at the die ? die Extruder The balance between the two should lead to the flow rate as well as pressure 8 Flow rate of the extruder (not including the die) Drag flow w Screw surface v d Barrel 9 Qd 0.5vdw v DN cos A dc w v d wc D tan A cos A wf Qd 0.5 D Nd c sin A cos A 2 2 (1) 10 wc D tan A cos A wf 11 Back pressure flow Dd sin A dp Qb ( ) 12 dl 3 c 2 12 Back pressure flow Dd sin A dp Qb ( ) 12 dl 3 c 2 pDd sin A Qb 12L 3 c 2 (2) 13 Net forward flow Qx pDd sin A Qx 0.5 D Nd c sin A cos A 12L 2 2 3 c 2 Linear relation between the net flow rate and head pressure. Assumption: viscosity is constant. The structure: extruder only not including die. (3) 14 Shaping Processes For Plastics - Extrusion The design parameters: those that define the geometry of the screw and barrel. The operating parameter: those that can be changed during the process to affect the output flow pDd sin A Qx 0.5 D Nd c sin A cos A 12L 2 Variable 2 3 c 2 15 Shaping Processes For Plastics - Extrusion Maximum pressure and maximum net flow rate 0 pDd sin A Qmax 0.5 D Nd c sin A cos A 12L 2 2 3 c 2 Maximum head pressure to cause no flow 6DNL cot A pmax 2 dc 16 Shaping Processes For Plastics - Extrusion Extruder characteristic Q Qmax pmax p 17 Shaping Processes For Plastics - Extrusion Determination of the operating point Pressure and Flow rate Qx K s p D Ks 128Ld die 4 d Die characteristic 18 Shaping Processes For Plastics - Extrusion Determination of the operating point Qx Die characteristic Qmax Operating point Extruder characteristic pmax p 19 Example: Given: diameter D=120 mm length =3.0 m channel depth =8.0 mm pitch = 95 mm viscosity = 75 pas head pressure = 4.0 Mpa Find: the rotational speed of the screw required to achieve a volumetric flow rate of 90 cm3/s 20 Solution to be filled in the classroom 21 Shaping Processes For Plastics - Extrusion Discussion A manufacturing process is to requirements. Requirements: quality, quantity, time, cost, green and sustainability. Quantity with respect to time is called production rate. The whole manufacturing system at the equipment level can be viewed as consisting of devices and materials. the material to meet 22 Shaping Processes For Plastics - Extrusion Discussion Both the device and material are under the manipulation from the external system that supplies energy or power and material. There are several parameters and variables in the manufacturing system: device parameter, process parameter, product parameter. 23 Shaping Processes For Plastics - Extrusion Discussion Device parameter also system or design parameter: the one category of parameters that describe the device, e.g., the diameter of the extruder, length of the extruder, etc. Process parameter also operating parameter: the one category of parameters that describe the process on the material, e.g., the rotational speed of the screw bar, heat energy supply, material supply rate, etc. Product parameter: the one category of parameters that describe or characterize the product which is the output from a manufacturing system, e.g., the flow rate, etc. 24 Shaping Processes For Plastics - Extrusion Discussion Manufacturing system design and control: 1. Device design: to determine the device parameter. 2. Process design: to determine the process configuration and parameter. 3. Product modification: design for process. 4. Device control. 5. Process control. Product quality, quantity, cost, time, green and sustainability 25