Foundation Walls

advertisement

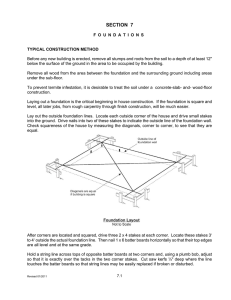

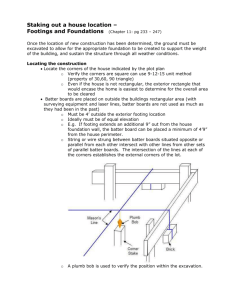

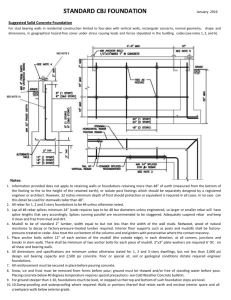

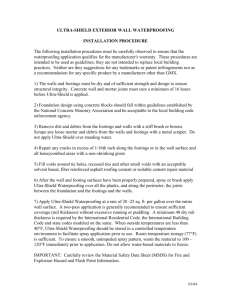

Building Foundations Foundation Walls Footings A base Monolithic construction Independent construction Foundation-Wall Footings Spread footings Undisturbed soil Footing Design Prevent settling or cracks Minimum of 12” below grade. Below frost line Thickness = thickness of foundation wall Width = 2x thickness of foundation wall Footing Reinforcement Rebar embedded 2 lengths of ½” diameter (#4) rebar Positioned minimum of 3” above bottom Footing Forms Form steel, lumber, or combination of lumber & plywood. Keyway Other Types of Footings Pier and post Stepped Footings Footing Drains 4” diameter pipes at base of footing Carries water away from house. Sloped at least 1/8” per foot Landscaping Fabric Poured-Concrete Foundation Walls Durable & water resistant Most building sites Support any type of house 8 –10” thick Min. compressive strength 2500 psi Most 8’ high Full Height Walls Formwork Reusable forms Wales Standard Wall Forms Wood or metal Built on site Prefabricated forms Snap-ties 3 –7 days Insulating Wall Forms ICFs (Insulating Concrete Forms) Permanent Basic components planks, sheets, or hollow blocks Standard wall Grid wall Placement Poured continuously without interruption Cold joint Water content Remove Air pockets Concrete vibrator (stinger) Crawl-space Walls Advantage – reduced cost Soil cover Ventilated Insulated Piers support Reinforcing Concrete Walls Rebar centered in wall Lintel Sill Plate Anchors Anchor bolts Metal strap anchors Sill sealer Foundation Wall Details Special features: Brick-veneer siding Utility Sleeves Foundation Vents And Windows Metal vents Rust-resistant steel frame windows Wood framing (pressure treated) Beam Pockets Girder flush with top of sill plate Stripping and Maintaining Forms Wood wedges (no metal pry bars) Stiff bristle (not wire) brush Form-release agent – Bio-slick Moisture Protection Bituminous (tar) coating Top of footings to finished grade level Backfilling Filling in excavation area Too soon, push in foundation walls First floor framing Temporary bracing Concrete Block Walls Popular for foundation walls No formwork Blocks inexpensive Work stopped and started Concrete Block Basics Concrete Masonry Unit (CMU) Head Joint Bed Joint Common bond Pilasters Protect from freezing & moisture Cutting Block Brick hammer and chisel Portable masonry saw Mortar Mortar bond strength depends on: Type & quantity Workability, or plasticity Surface texture bedding areas Rate at which masonry units absorb moisture from mortar Water retention Skill of person laying block Mortar Mixtures Portland cement, hydrated lime, sand, & water. Prepackaged mortar mix Type N Type M Type S Type O Mixing and Placing Mortar Evaporation Hydration 2 ½ hour when air temp is 80ºF or higher 3 ½ hours when air temp is below 80ºF. Laying Block Foundation Walls Skilled masons Corners built first Story pole (course pole) Intersections Control joint Tooling the Joints Weather tight joints & neat block walls “Thumbprint hard” Tooling compacts Head joints, then bed joints Completing the Walls Hollow block walls capped Strengthened with rebar Moisture Protection Damp proofed or waterproofed Parging Radon Colorless & odorless radioactive gas Extremely toxic Lung cancer Soluble in water 9X heavier than air Radon-Resistant Construction Gas-permeable layer Soil-gas retarder Sealants Vent pipe Cap course Review 1. 2. 3. 4. 5. 6. 7. What is the minimum depth required for an exterior-wall footing? Describe the type and position of reinforcement that is commonly added to strengthen a footing. What is a keyway and how is it formed? For nearly all poured-concrete foundation walls, formwork must be constructed for each wall face. What holds the formwork together? What creates a cold joint? Why are the joints in a concrete block wall tooled? When using mortar, why is it helpful to know the differences between hydration and evaporation?