Fasteners: Threaded & Non-Threaded Types, Measurement & Repair

advertisement

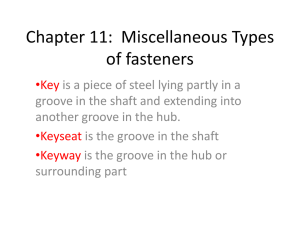

Fasteners Chapter 5 Fasteners Objectives • Describe USC threaded-fastener measuring system • Describe metric threaded measuring system • Identify grade markings of threaded fasteners • List and describe common thread repair tools Objectives • Identify and explain purpose of common nonthreaded fasteners • Explain importance of wire gauge sizes • Identify common types of electrical fasteners Introduction • Automotive components are held together with fasteners • Much of a technician’s time is spent removing and installing fasteners • There are two basic groups – Threaded – Non-threaded Threaded Fasteners • Most common type of fastener – Use spiral threads to wedge parts together • Fastener Sizing and Torquing – Must be correct strength and size – Must be replaced with like size and quality – Never install a heavier sheer pin to “fix” a problem Threaded Fasteners • Screws – – – – One of the most common threaded fasteners Fits into a threaded hole Different designs to meet attaching needs Some require a wrench to install, others can be installed with screwdrivers – Often classed by shape of head Threaded Fasteners • Bolts – Use a nut instead of a threaded hole – Usually goes through parts that don’t have threads – Most have hex-shaped head – Two different types • Standard • Torque-to-yield Threaded Fasteners • Studs – Fastener with no head and threads on both ends • Nuts – Used with bolts and studs – Many different designs – Can be specialized to specific applications Torque-to-Yield Bolt Installation • Follow all manufacturer instructions on torquing the bolt • Typically first two steps involve an actual ft.lbs reading on a torque meter Torque-to-Yield Bolt Installation • Final step requires tightening the fastener a specified number of degrees • Greatly reduces effect of friction on torque readings Threaded Fasteners • Washers – Often used to distribute loads – Prevent a nut from becoming loose – Prevent damage to a machined surface Washers • • • • Flat Spring Lock External tooth lock Internal tooth lock Nuts Threaded Fasteners • U.S. (English) Thread Sizes – Manufactured to Unified System specifications in Fractions of an Inch – Threads can be course or fine depending on the number of threads per inch – Bolt size is determined by shank diameter, bolt length, and threads per inch Bolt Identification (Cont’d) Bolt Identification • Diameter – Measured across the threaded area • Thread pitch (English system) – The number of threads per inch • Thread pitch (Metric system) – The distance in millimeters between two adjacent threads Metric Size Bolt Identification Example • A metric size bolt that is identified as 6mm x 30mm x 1.25mm: – Has a shank diameter of 6 millimeters. – Is 30 millimeters long from the bottom of the head to the end of the shank. – Has a distance of 1.25 millimeters between its threads. Imperial Size Bolt Identification Example • An Imperial size bolt that is identified as 3/8" x 2" x 24: – Has a shank diameter of 3/8 inch. – Is 2 inches long from the bottom of the head to the end of the shank. – Has 24 threads per inch. Threaded Fasteners • Metric Thread Sizes – Same basic measurements as U.S. (English) bolts – Pitch number differentiates between fine and coarse as opposed to NC or NF ratings Measuring Devices (Cont’d) • Screw pitch gauge / Thread pitch gauge – Is used to determine thread pitch of a bolt or screw. • Machinist’s rule – Is usually used to measure items that don’t require extremely close tolerances, such as bolt lengths Bolt Grade Markings • Customary (inch) bolts – Identification marks correspond to bolt strength. – Increasing numbers represent increasing strength. • Metric bolts – Identification class numbers correspond to bolt strength. – Increasing numbers represent increasing strength. • Metric and SAE size wrenches are not interchangeable. Threaded Fasteners • Hardness and Strength – Strength is identified by grade markings on the bolt head – Standards are set by the Society of Automotive Engineers (SAE) – Tensile strength is amount of pressure the fastener can take before it breaks Grade Markings Threaded Fasteners • Fastener Torque – Must be tightened to the correct amount – Not enough torque causes fastener to loosen – Too much leads to breakage Torque Wrenches Thread Repair Tools • • • • Tap and Die Set Heilicoil Thread Restorer and Chasers Screw Extractor or EZ-Out (Brand Name) Thread Repair Tools • Tap and Die Sets – Dies are used to make external threads – Taper taps must extend through hole to work properly – Bottoming taps thread to bottom of hole Thread Repair Tools • Helicoils – Threaded device threads into a hole and provides internal threads for a bolt – Must be used in conjunction with a properly sized drill and tap Heilicoil Thread Repair Tools • Thread Restorers and Chasers – Restoring files are used to smooth and shape damaged threads – Thread chasers fit over the damaged thread like a fastener • Turned back and forth over damaged threads until repaired Thread Restorer files TAP Screw Extractor-EZ Out Nonthreaded Fasteners • Snap Rings – Often used to hold parts in place on a shaft – Made from high quality steel that retains its shape – Snap rings can be internal or external Electrical Wire • Replacement wire must be at least as heavy as the wire being repaired • Always try to match wire color • Use diagrams to pinpoint wire purpose before repairing Electrical Wire size Wire Sizes Wire Crimpers Connectors • Two types of connectors-Solder and solderless • Soldering – Best repair method for wires – Adds little or no resistance to circuit – Use only resin based solder in automotive circuits Acid based solder can add resistance to circuit. • Terminal Connectors – Device fastened to end of wire, allowing connection to a component – Most are covered with an insulator Connectors • Molded and Shell Connectors – Many different shapes and sizes – Matched in color, shape, purpose to help prevent crossing circuits Wire Connectors Connectors • Butt Connectors – Connects two wires together – Quick and easy to install, but may add resistance • Keys Nonthreaded Fasteners – Used to retain a part on a shaft – Fits into a slot called a keyway – Locks the two parts into position Nonthreaded Fasteners • Splines – Long teeth are formed onto inside or outside of a part – Matching part has splines on opposite side Nonthreaded Fasteners • Rivets – Used to hold parts together that are hardly ever disassembled – Made from soft materials – Rivets are removed by a drill or chisel • Then drive shaft out with a punch Rivets Summary • Threads are measured and classified using U.S. (English) or metric system • Fasteners must be used as designed • Nonthreaded fasteners are also common • Electrical terminals and wiring must be maintained