10.3 Common Threaded Fasteners - Ivy Tech -

advertisement

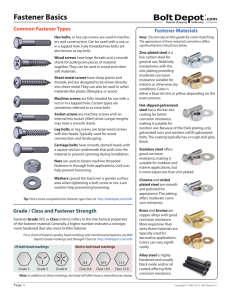

10-3 Common Threaded Fasteners •Machine screws have either fine or course threads and are available in a variety of heads. They may be used in tapped holes or with nuts •Cap screws are threaded fasteners that join two or more parts by passing through a clearance hole in one part and screwing into a tapped hole in the other. •Captive screws remain attached to the panel or parent material even when the mating part is disengaged. They are used to meet military requirements, prevent screws from being lost, or speed assembly & dis-assembly or prevent damage from loose screws falling into moving parts or electrical circuits. • Tapping screws cut or form a mating thread when driven into preformed holes • A bolt is a threaded fastener that passes through a clearance hole into a nut • Studs are shafts threaded at both ends THREADED FASTENERS SCREWS Head styles • • • • • • • • • Hex and square Pan Binding Washer Oval Flat Fillister Truss 12 point THREADED FASTENERS BOLTS THREADED FASTENERS STUDS Drawing a nut and bolt • Nuts and bolts may be drawn on some assembly drawings • Conventional drawing practice is to show the nuts and bolt heads in the across-corners position in all views • Approximate head proportions are shown on the next two slides THREADED FASTENERS HEAD PROPORTIONS THREADED FASTENERS HEAD PROPORTIONS Point styles • • • • • • The point of a fastener is the configuration of the end of the shank Cup Flat Cone Oval Half-dog Property classes of fasteners Inch and metric • Inch fasteners: the strength is determined by the size of the fastener and the material from which it is made. Property classes are defined by SAE or ASTM. Table 10-1 lists properties • Metric fasteners: the property classes are designated with numbers with increasing numbers generally representing increasing tensile strength. Nuts • Style 1 and Style 2 for metric nuts have replaced the terms regular and thick • A locknut is a nut with special internal means for gripping a threaded fastener to prevent rotation • Captive or self-retaining nuts provide a permanent, strong, multiple-thread fastener for use on this materials Washers • • • • • Flat Conical Helical spring Tooth lock Spring Terminology • Tap drill size for a threaded (tapped)hole is a diameter equal to the minor diameter of the thread • Clearance drill size permits the free passage of a bolt is a diameter slightly greater than the major diameter of the bolt 10-4 Keeping fasteners tight • Free-spinning devices include toothed and spring lock washers and screws and bolts with washerlike heads. The fasteners spin free in the clamping direction which makes them easy to assemble. • Prevailing-torque methods make use of increased friction between the nut and bolt. Metallic types usually have deformed threads or contoured thread profiles that jam the threads on assembly. • Chemical locking is achieved by coating the fastener with an adhesive.