Module 2a

advertisement

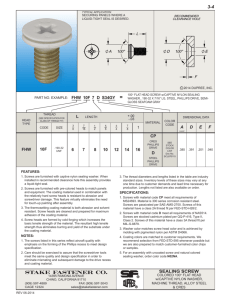

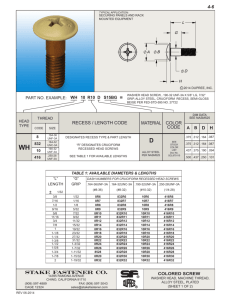

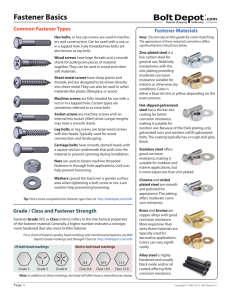

ME 330 Manufacturing Processes MECHANICAL ASSEMBLY: Joining Methods using Fasteners Overview of processes Principle of the process Structure and configuration Process modeling Defects Design For Manufacturing (DFM) Process variation Mechanical Assembly: Definition Use of various methods to mechanically attach two or more parts together. This can be done by Two Major Types of Mechanical Assembly 1. allow for disassembly Use of the third part component Use of the deformation between two components to be assembled. 2. create a permanent joint with no possibility of disassembly Adhesion and bonding Pros of Mechanical Assembly 1. Ease of assembly – can be accomplished with relative ease by unskilled workers Minimum of special tooling required Can be done in a relatively short time 2. Ease of disassembly – at least for the methods that permit disassembly Some disassembly is required for most products to perform maintenance and repair Principle of the process Structure and configuration Process modeling Defects Design For Manufacturing (DFM) Process variation Use of the third part component - fastener for the joining with a possibility of disassembly See for a good overview: http://www.fastenal.com/web/search/products/_/N-gj4wao& http://www.mcmaster.com/#fastening-joining Fastens: Screws, Bolts, and Nuts 1. Screw - externally threaded fastener generally assembled into a blind threaded hole. Some screws are self-tapping so there is no need to tap the hole. 2. Bolt - externally threaded fastener inserted into through holes and "screwed" into a nut on the opposite side. 3. Nut - internally threaded fastener having standard threads that match those on bolts of the same diameter, pitch, and thread form. Self-Tapping Screws Designed to form or cut threads in a pre-existing hole into which it is being turned. For thicker materials, a hole needs to be drilled first, or cracking may result. Nut Types Hex nut: plain type Wing nut: designed for hand tightening Nylon insert lock nut: has nylon insert to resist loosening. Also called Nylock nut Castle nut: used with a cotter pin to prevent loosening Some Facts About Screws and Bolts 1. Screws and bolts come in a variety of sizes, threads, and shapes. 2. Much standardization in threaded fasteners, which promotes interchangeability. 3. Canada and US is converting to metric, further reducing variations. 4. Differences between threaded fasteners affect tooling Example: different screw head styles and sizes require different screwdriver designs. Head Styles on Screws Common head styles available on screws Courtesy of www.mikesenese.com Drive Styles on Screws Common drive styles available on screws Courtesy of www.mikesenese.com Setscrews Assembly functions such as fastening collars, gears, and pulleys to shafts Assembly enhancement: Screw Thread Inserts Internally threaded plugs or wire coils designed to be inserted into an unthreaded hole and accept an externally threaded fastener Assemble into weaker materials to provide strong threads Expand when screwed into, in some cases (a) before insertion, and (b) after insertion into hole and screw is turned into insert Assembly enhancement: Washer Hardware component often used with threaded fasteners to ensure tightness of a mechanical joint. Simplest form = flat ring of thin sheet metal. Functions: 1. 2. 3. 4. 5. Distribute stresses Provide support for large clearance holes Protect part surfaces and may help seal Increases spring tension Resists inadvertent unfastening Washer Types a) b) c) d) plain (flat) washers spring washers: dampens vibration and resists loosing of bolt/screw Lock washer: designed to resist loosening of bolt/screw split lock washer: designed to resist loosening of bolt/screw (d) Use of the third part component - fastener for the permeant joining Rivets Unthreaded, headed pins used to join two or more parts by passing the pin through holes in parts and forming a second head in the pin on the opposite side Five Basic Types of Rivets (a) Solid, (b) tubular, (c) sem itubular, (d) bifurcated, and (e) compression Applications and Advantages of Rivets 1. Used primarily for lap joints. 2. A primary fastening method in aircraft and aerospace industries. 3. Advantages: High production rates Simplicity Dependability Low cost Tooling and Methods for Rivets 1. Impact - pneumatic hammer delivers a succession of blows to upset rivet. 2. Steady compression - riveting tool applies a continuous squeezing pressure to upset rivet. 3. Combination of impact and compression. Fastening with Eyelets (a) Eyelet, (b) assembly sequence: (1) inserting eyelet through holes and (2) setting operation Summary 1. Mechanical assembly concept – providing force constraints on two parts mechanically. 2. Assembly can be: permanent and disassemble. 3. Dissemble possibility: bolts-nuts, screw. 4. Permanent: rivets. 5. Rives: cheap, efficient used in aircraft, ship.