here…

advertisement

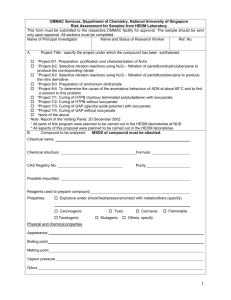

FEEM Health & Safety Working Group Meeting Brussels 12 – 13 March 2013 Lab nitration in a different way? Presentation by Walter Panchyrz Eurodyn Sprengmittel GmbH in Burbach-Würgendorf/Germany Lab nitration in a different way? For more than 100 years, customers like to use the good old dynamites for digging in the ground…, … and right from the beginning of their use, accidents have happened forcing the manufacturers to find out what went wrong in the course of the process and how to protect people from harm. ? Alfred Nobel For more than 100 years, the dynamite manufacturers have implemented safer processes and have improved their safety standards. Production of nitro glycol Nitration control room Centrifuge Rinse & separation facilities Nitration control room Nitro glycol storage Chemists realized that one major fact to “deal with the fire” is the purity of raw materials to not run into the risk to open “Pandora’s box” during the manufacturing process. For example: Certificate including proof of cleaning in place Impurities in glycol from transport EGDN how it should look like (clear and pure) Drops of grease as a “gift” from transport company Blast oil phase how it looks like in the process (cloudy) Quality control is mandatory! Moreover chemists developed clear standards for raw material quality controls, e.g. glycerin and MEG. MEG Test Schedule Specification MEG Work Instructions Controls Why lab nitration? Prior to the production process, a lab nitration is undertaken using a small quantity of MEG or glycerin in order to generate a reaction and to previously a) discover any side reactions (worst case: fumes, impurities) b) make sure that the separation of nitration acids and product will proceed in the production process as required. Chemical equation for glycol: (nitric acid) Schlegel bulb (water) Quantity: ~ 60 gr 100 years lab nitration without an accident…? …or sitting on a bomb? Brain storming about protective measures in the lab Idea # 1: Same mass, same energy -> protect staff Let him work in a protected way: Result (after shock wave > 7000 m/sec): Blasting site (before) (wearing a Kevlar fibre protective vest) Kevlar fibre (after) does not work But idea without benefit! Blasting site (after) Brain storming about protective measures in the lab Idea # 2: New lab equipment, no mass reduction -> run the process automatically No mass reduction possible, idea without benefit! Brain storming about protective measures in the lab Idea # 3: Implement new technology -> use a micro reactor Micro reactor An idea with benefit as the same result is achieved by pre-process testing smaller quantities at lower risk for lab staff! Temper bath The results with only ~ 1 gr mass: Before stirring Start good EGDN +120 sec good EGDN poor EGDN poor EGDN The change after implementing the new technology The benefit: Achieving the same results at a much higher safety standard level! Another benefit: Improve work safety for our staff… …and keep authorities happy and smiling!

![[VO(H2O)5]H[PMo12O40]-catalyzed nitration of alkanes with nitric acid](http://s3.studylib.net/store/data/007395962_1-c5684ccdbf5a6a8d13576cb676ea7c0b-300x300.png)