Management Information Systems (MIS)

advertisement

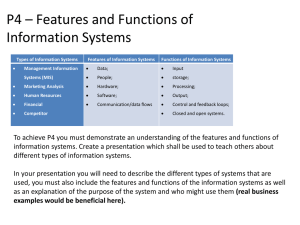

Management information systems (MIS) 1 Typical problems faced by mid-level managers • Should a new piece of equipment be purchased or lease the equipment? • Is the idle cash of your firm being invested wisely? • What are the best selling products in current or next season? • How many and what types of workers will be needed to staff a new plant? • The above are usually short-term problems. 2 Management Information Systems (MIS) • MIS is one type of information systems dealing with tactical plans for mid-level managers. • Tactical = solve short-term problems with required skills. • MIS focus on operational efficiency: monitor & control operations, allocate resources effectively. • MIS generate standard, routine reports as outputs; and use data/information as inputs from TPS (see next slide). • Bottom-level managers also use reports from MIS for operational tasks. 3 MISs related to TPSs and databases 4 Sources of inputs into MISs • Internal source: inputs are those information processed by the organization’s TPSs and placed in a database of valid transactions, and those inputs from databases of other corporate branches of the organizations. • External source: inputs are those data or information obtained from the internet, extranet, customers, suppliers, competitors, partners and stockholders. 5 Difference between TPS and MIS • TPS help to support and execute slow, frequent, labour-intensive and repetitive operational tasks in an organisation. • MIS help managers to control and monitor the above operational tasks (e.g. resource allocation) with important information or reports. 6 Scheduled reports from MISs • Produced periodically e.g. daily, weekly, monthly etc. 2 types of scheduled reports: Summary report – gives important totals, averages or key data on past activities of the organization. E.g. lists of total weekly sales by salesperson, or by product, or by sales region. Key-indicator report: summarise previous period’s critical activities and is available at the start of each workday for managers to take quick and corrective actions on important problems. E.g. previous day’s sales volume or inventory level. 7 Exceptions reports from MIS • Warn managers when results from an operation exceed or do not meet the expected standard which is set by some parameters as input into the MIS by managers. • Automatically produced when there is an unusual situation that requires management action. • E.g. list of salespersons whose sales fall in the top and bottom 10%. • E.g. list of all plants that have logged more overtime hours than expected for the week. • E.g. list of all inventory items below certain level => prevent running out of stock, thus need to reorder. 8 Demand reports from MISs • Also called ad-hoc reports. • Reports that managers need quickly but may never be needed again. • Contains information that the manager needs to solve a unique problem. • E.g. When there is a sudden high overtime earnings at certain plants, the manager may request a production record of each plant for the week, and a list of total number of employees absent during the week by plant and by job title. 9 Drill down reports from MISs • Several levels of reports that provide increasingly detailed data about a situation. • 1st level: high-level with overall view (little detail) of information. • 4th level: low-level with very detailed information about an item. 10 Reports Generated by an MIS 11 Reports Generated by an MIS 12 Characteristics of information from MIS reports • • • • Periodic in nature (scheduled reports) Unexpected findings (exceptions reports) Ad hoc basis (demand reports) Comparative in nature: information is not just descriptive, but alert managers to differences from accepted standards or to results that are outside normal range so that managers can take quick action. This gives feedback when output is outside accepted standards. 13 Characteristics of information in MIS reports • Summary form: not much detailed. E.g. a credit manager is not interested in the a detailed listing of each customer account’s balance, but interested in summary information on credit performance of accounts that are overdue. • Detailed information is not useful to managers. 14 Guidelines for designing MIS Reports 15 E.g. of MISs in 4 business functions 16 Overview of a Financial MIS 17 Budgeting system - accounting & finance MIS • Track actual revenues & expenses and compare these amounts to expected revenues & expenses. • Compare budget amounts to those of previous periods, or of other divisions. • Comparisons of budget data allow managers to assess how they use their resources to achieve their goals. • E.g. to find the amount of money actually spent in the purchasing department on supervisory versus clerical staff. Managers then compare those amounts to the amounts spent by other purchasing departments. 18 Cash management system accounting & finance MIS • Monitor that the organization has sufficient cash to meet its needs: its working capital need and its long-term asset acquisition plans. • Assess excess funds from any period to use through investments. • Assess any borrowing power to meet organization’s cash needs in periods of insufficient cash flow. • Produce cash flow reports showing the cash flow for each month. 19 Overview of a Manufacturing MIS 20 Materials requirements planning (MRP) - a Manufacturing MIS • Inputs to MRP: master production schedule, inventory files, lists of raw materials and components needed to create each product. • Processes of MRP: calculations & record keeping to ensure the proper amount of the right materials are available for production processes at the right time. • Objectives: meet customer’s delivery requirements , ensure unnecessary buildups of materials don’t occur, overtime or extra costs are not incurred. • Outputs: list of purchase orders ensuring right materials are ordered at the right time in the most economical quantities. 21 Just-in-Time (JIT) - a tactical approach to production • Beneficial to repetitive production. • Purpose is to eliminate waste in the use of equipment, parts, space, workers’ time, materials, inventories etc. • Processes: inventories and materials are delivered just before they are used in production => smooth flow of operations required. • Must maintain close relationships with suppliers of materials for good co-operation. 22 23 Overview of a Marketing MIS 24 Pricing Systems – marketing MIS • Purpose: help managers set prices for products & services as prices can affect the sales volume and profitability. • Inputs: expected competitive prices, expected customer price index, actual production costs, expected customer disposable income, expected advertising expenditures, discounts etc. • Output: a pricing model enabling the manager to vary the inputs to identify the best price under different conditions and constraints. 25