PowerPoint Slides

advertisement

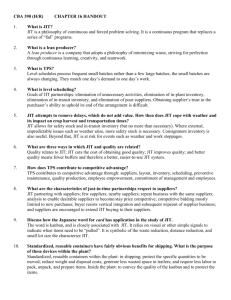

Chapter 7 Just-In-Time and Lean Systems Just-In-Time (JIT) • Getting the right goods to the right place at the right time. • In an ideal JIT system, inventory = ?? • JIT is a goal and a philosophy. Lean System: A Broad View of JIT • Extending JIT philosophy to the entire organization, it is the Lean System. • In a lean system, everything is “right”, therefore no waste existing. What are “Wastes”? • Waste is anything that doesn’t add value: time, money, resource, material, space, energy, labor activity, … • What may cause wastes? – Inventory – Unsynchronized production – Unstreamlined layouts – Unnecessary material handling – Scrap & rework –… Central Beliefs of Philosophy of JIT / Lean System • • • • • • Elimination of waste Broad view of operations Simplicity Continuous improvement Visibility Flexibility Eliminate Waste • Anything in an operation that does not add value is waste. • Method A and method B can both get a task done. If A can do it better, or faster, or in a cheaper way, then there exist wastes in method B. Everyone Has a Broad View of Organization • Instead of focusing on the assigned jobs only, a worker has a broad view of the organization: its mission and goals, and place his job in that big picture. Simplicity • If a problem can be solved in a simple way, do not go complicate. Continuous Improvement • Good enough is not good enough. • “Kaizen blitz” is a Japanese way of implementing continuous improvement idea. It is a few day’s intensive work of a cross-functional team aiming at resolving a bite-size chunk of a problem. Visibility • Visibility is to make waste visible. • Waste can only be eliminated after it’s discovered. • Clutter and inventory hide waste. • JIT requires clean facilities and open space so that no waste can be hidden. Flexibility • Flexible so as to adapt to changes in the demand and environment. – Volume flexibility – Variety flexibility Three Elements that Make JIT Work • Just-in-time manufacturing • Total quality management • Respect for people 12 JIT Manufacturing • • • • • Kanbans & pull production systems Quick setups & small lots Uniform plant loading Flexible resources Efficient facility layouts 13 Pull Production • Process is driven by real demands (rather than demand forecasts). • Doing nothing unless a real demand calls (demand pull). • All work stations are “demand pull”. 14 Kanban Production System • A “pull production” system. • Real demand information is passed in relay backward from the last work station by using ‘kanbans (cards)’. • Each work station works according to the kanbans passed from the next station. • Each work station is responsible to pass proper kanbans to the previous station. 15 16 Illustration of Kanban in Textbook © Wiley 2010 17 18 Number of Kanbans in a Withdraw Work Station DT S N C N = number of containers in a withdraw station D = demand rate at the withdraw station T = lead time from supply station C = container size S = safety stock to protect against uncertainty 19 Quick Setups & Small Lots • Setup times = time required to get the machine ready – cleaning, calibrating, changing tools, ... • Internal setups – The machine must stop when doing setup. • External setups – Setup can be performed when machine is running. 20 Uniform Plant Loading • “Leveling” of the production schedule so that the production of a product is evenly spread over the planning horizon in small batches. • Leveling the schedule can have big impact along whole supply chain. 21 An Example of Uniform Plant Loading Weekly Production Required A B C D E Traditional Production Plan Monday Tuesday AAAAA BBBBB AAAAA BBBBB JIT Plan with Level Scheduling Monday Tuesday AABBBB AABBBB CDEE CDEE 10 units 20 units 5 units 5 units 10 units Wednesday BBBBB BBBBB Thursday DDDDD CCCCC Friday EEEEE EEEEE Wednesday AABBBB CDEE Thursday AABBBB CDEE Friday AABBBB CDEE © Wiley 2010 22 Flexible Resources • General purpose equipment: – E.g.: drills, lathes, printer-fax-copiers, etc. – Capable of being setup to do many different things • Multifunctional workers: – Cross-trained to perform several different duties 23 Efficient Facility Layouts • Workstations in close physical proximity to reduce transport & movement • Streamlined flow of material • Often uses: – Cellular Manufacturing (instead of job shops) – U-shaped lines: (allows material handler to quickly drop off materials & pick up finished work) 24 Cellular Manufacturing (Group Technology) • Components are grouped according to their similarities. • Machines are grouped in cells so that a cell can complete the processing of some groups of components • Similar components are processed completely in a cell composed of dissimilar machines. 25 Job Shop Layout 26 Cellular Manufacturing (Group Technology) 27 TQM & JIT • • • • Quality at the Source Jidoka (authority to stop line) Poka-yoke (foolproof the process) Preventive maintenance 28 Respect for People: The Role of Workers • • • • • • • • Cross-trained workers Actively engaged in problem-solving Workers are empowered Everyone responsible for quality Workers gather performance data Team approaches used for problem-solving Decision made bottom-up Workers responsible for preventive maintenance 29 Respect for People: The Role of Management • Responsible for culture of mutual trust • Serve as coaches & facilitators • Support culture with appropriate incentive system • Responsible for developing workers • Provide multi-functional training • Facilitate teamwork 30 Supplier Relations & JIT • • • • • Use single-source suppliers Build long-term relationships Co-locate facilities to reduce transport Stable delivery schedules Share cost & other information 31 Benefits of JIT • • • • • • • • Smaller inventories Improved quality Reduced space requirements Shorter lead times Lower production costs Increased productivity Increased machine utilization Greater flexibility 32 Implementing JIT Manufacturing • Identify & fix problems • Reorganize workplace – Remove clutter & designate storage • Reduce setup times • Reduce lot sizes & lead times • Implement layout changes – Cellular manufacturing & close proximity • Switch to pull production • Extend methods to suppliers 33 Implementing JIT Is a Process of Continuous Improvement © Wiley 2010 34 JIT in Services • • • • • • Multifunctional workers Reduce cycle times Minimize setups Parallel processing Good housekeeping Simple, highly-visible flow of work 35