Introduction to Sherlock 3.0

advertisement

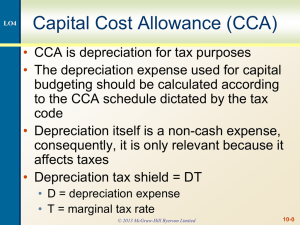

Introduction to Sherlock 3.0 Nathan Blattau, Ph.D. Frank Pittelli, Ph.D. © 2004 - 2010 2007 o Nathan Blattau, Ph.D. - Senior Vice President Has been involved in the packaging and reliability of electronic equipment for more than ten years. His specialties include best practices in design for reliability, robustness of Pb-free, failure analysis, accelerated test plan development, finite element analysis, solder joint reliability, fracture, and fatigue mechanics of materials. o Frank Pittelli, Ph.D. - Senior Software Architect Has over 30 years of experience in the computer industry, including research, system design and development, academic and professional teaching, high-level analysis, consulting and product development. © 2004 - 2010 2007 o New features in the upcoming Sherlock 3.0 release o o o o o o © 2004 - 2010 2007 Global Part Database FEA 3D Model Sub-Assembly Analysis FEA 3D Viewer Result Management Failure Rate - Telcordia SR-332 Global Part Database Created to allow Sherlock users to store and share part data across their own projects and with other Sherlock users. Interaction with other commercial or customer databases is also available and is undergoing testing © 2004 - 2010 2007 Global Part Database CCA #1 Parts List Local Part Database CCA #2 Parts List Local Part Database Global Part Database Operates 24x7 and is accessible via the Internet Provides users with private “cloud” storage for their own confirmed part data Allows users to view ranked alternative part data while maintaining complete privacy for all users. Community sharing reduces data entry and increases data accuracy © 2004 - 2010 2007 Global Part Database Demo © 2004 - 2010 2007 FEA 3D Modeling ICT and Shock / Vibration Analysis fully 3D elements for the PCB, components and mount pts increase simulation accuracy more reliable meshing algorithm increased analysis flexibility • sub-assemblies, heatsinks, chassis analysis FEA Engine © 2004 - 2010 2007 Multi-core and 64 bit support Faster analysis Sub-Assembly Analysis Attach one or more CCA subassemblies to a primary CCA mezzanine cards supported by standoffs edge-connected cards Sherlock automatically analyzes the main CCA and all CCA sub-assemblies during a single ICT or Shock/Vibration analysis task Layer results and component results automatically generated for all circuit cards Edge-connected card © 2004 - 2010 2007 Sub-Assembly Analysis Demo © 2004 - 2010 2007 FEA 3D Viewer Allows users to visualize 3D models and results Interactively view 3D model with colors based on displacement or strain values. Optionally amplify the displacement results to visualize small changes Publication-ready image files can be created at any time Viewer can be launched from inside of Sherlock or directly from the desktop. © 2004 - 2010 2007 FEA 3D Viewer Demo © 2004 - 2010 2007 Result Management CCA inputs and analysis results can be saved for later review and/or comparison. Arbitrarily named result files can be stored anywhere in the file system allows users to organize results in any convenient manner Can be launched from within Sherlock or directly from the desktop. Multiple viewers can be active at the same time, allowing side-byside review of past and present analysis results. © 2004 - 2010 2007 Result Management Archived results contain all input information (BOM, layers, stackup) so you can track what has changed between simulations © 2004 - 2010 2007 Result Management Demo © 2004 - 2010 2007 How Failure Rate - Telcordia SR-332 Enhanced to allow users to choose between the following models: MIL-217 and SR-332 Sherlock automatically computes a failure rate for each CCA component based on the part data currently defined in the Parts List Uniform set of Failure Classes has been defined by DfR Solutions to be assigned to each CCA part. Failure class designators and failure rate related part properties can be stored in the Sherlock local and global part databases by part number © 2004 - 2010 2007 significantly reduces data entry and maintenance across a collection of CCAs and projects over a period of time. Failure Rate Demo © 2004 - 2010 2007 Thank You! Questions?