File - Dingwall CDT

advertisement

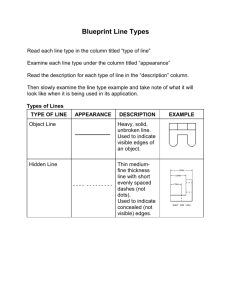

Department of Technological Education Graphic Communication British Standards Knowledge & Understanding British Standards - Drawing Conventions Line Types Dimensioning • Why? • We have a greater understanding of why we are doing things in a certain way. • We have an broader understanding of the implications it has on industry. What does British standards mean to you? • The British Standards Institution (BSI) is the UK's national standards body. • It brings together representatives from a range of organisations to develop formal Standards for the benefit of UK business and consumers. British Standards • Standards make our lives easier, safer and healthier. Without them, everyday actions we take for granted would be unpredictable. • Standards help to make many of the products we use safer and more reliable. • Once you are familiar with the idea of products meeting Standards, it will help you to understand how Standards are met in order to keep us safe and sound. British Standards • In Short they are set methods/procedures that allow us to consistently reproduce quality products. • With regards to Drawings BS allows standardisation ie. It creates a common language between professional people. British Standards –Drawing • BS EN ISO 128-20:2001 - Technical drawings. General principles of presentation. Basic conventions for lines. • BS EN ISO 128-21:2001 - Technical drawings. General principles of presentation. Preparation of lines by CAD systems. • BS EN ISO 5456-2:1999 - Technical drawings. Projection methods. Orthographic representations. • BS 308-2.3:1995 -Technical drawings. Dimensioning and tolerancing. • BS ISO 128-40:2001 -Technical drawings. General principles of presentation. Basic conventions for cuts and sections. • Visible Outlines and Edges. A continuous thick line. • Construction, projection and dimension projection. A continuous thin line. These are the two basic line thicknesses recommended in the BS. However you will see there are variations in Their use. • Hidden outlines and edges. A broken thin line. Dashed lines should start on a line & finish on a line. Dashes and spaces should be of even length and spacing. • Centre Lines. Thin line. Long dash – short dash. Centre lines should extend slightly passed the feature it applies to. They should not stop at another line. Where centres points are defined – long dashes should cross. • Section lines (cutting planes) • Fold lines Like the centre line but ends and change of direction are thick Thin line. Chain of long dash and two short dashes. Question? Solution! Question? Solution! Section Line Fold Line Centre line • When applying measurements there are some simple rules to follow! 1 Projection lines should be thin and disconnected from the part. 12 2 Arrow heads should be narrow Filled 17 14 3 Sizes should be written Clearly ABOVE the line • Two methods we should know for now! 12 12 17 14 29 43 Linear Dimensioning Parallel Dimensioning • For A radius… The dimension line should pass through the centre point of the arc. The dimension line should have one arrowhead that touches the arc. R10 The symbol R is placed in front of the dimension. • For a Diameter… The dimension line should pass through the centre point of the arc. The dimension line should have two arrowheads that Touch the arc. The symbol Ǿ is placed in front of the dimension. Ǿ 10 • For Angles… Curved double headed arrow between lines. The angle is written outside the Arrow. Alternatively Arrows can be Outside with the angle written Lines. 30° 30° • • • • Angle used is 45° Spacing equal 4mm For Exploded views direction of hatching is the same. For assembled views 1. Part 1 in one direction 2. Part 2 in the opposite direction with same spacing. 3. Part 3 spacing reduced to half. Assembled Exploded We do not Hatch… 1. Nuts, Bolts, washers. 2. Keys, Webs, Shaft. 3. Spindles, Gears, Pins. – Note – Shafts are only sectioned if cut through the cross sectional area. Go for it! • BSI-Education.org/BritishStandards