Design and Operation of Large Scale RNA production v2

advertisement

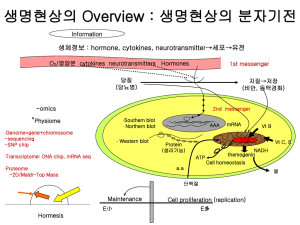

Design and Operation of Large Scale RNA production Daniel Jacinski, PhD candidate College of Pharmacy Problem • For our customers we need to produce RNA in large scale. • • High cost and high amounts of waste are preventing scaling up of production. For large scale synthesis, the goal is to generate 1 gram of RNA with one synthesis run RNA Background Central Dogma Replication DNA Transcription miRNA RNA Translation Protein Blocks protein production siRNA Background • siRNA • Small Interfering RNA • • Primarily 21 nucleotides in length Double stranded • Mimics miRNA and specifically controls gene regulation • Degrades mRNA preventing protein production • Great interest in using siRNA in therapeutics for cancers and viral infections • New class of Drug currently being discovered and developed Why produce siRNA • As a new class of drugs there is a high interest to use siRNA for the treatment of disease • Large production of siRNA strands can be used by • • • Researchers Clinicians for clinical trials Eventually as a pharmaceuticals in humans • We want to produce large amounts of RNA, while reducing cost, to supply to potential customers. Large Scale RNA synthesis – RNAi in Big Pharma • Big Pharma is actively exploring RNAi for novel cancer treatments • Is seen as the next phase in drug discovery • RNAi as the therapy or RNA as the target for treatment http://seekingalpha.com/article/2329785-celsions-egen-acquisition-bringsimmunotherapy-and-rna-therapeutics-to-its-cancer-platform RNA in Clinical Trials Watts JK, Corey DR. Silencing disease genes in the laboratory and the clinic. Journal of Pathology; 2012, 226: 365-379. DOI: 10.1002/path.2993 RNA synthesis • This scheme is for DNA, for RNA there is a 2’ TBDMS protecting group to protect the highly reactive 2’OH on RNA RNA synthesis • Basic Synthetic Cycle Steps • The Detritylation Step (deblocking) • The Coupling (Activation) Step • The Capping Step • The Oxidation Step • Monomers used in synthesis are different from what is used for natural RNA production • Phosphoramidite chemistry RNA synthesis – Most Important Steps for high yield • Detritylation • N-1 nucleotide must have the 5’ group deprotected to add the next monomer • Coupling • • Addition of the next monomer – RNA takes much longer than DNA At least 5-6 minutes per base • WATER KILLS COUPLING EFFICIENCY • • Probably the most important aspect for synthesis efficiency Argon gas normally used to keep synthesis in moisture free environment Post Synthesis Procedure • Cleavage off the beads is the first step of the postsynthesis procedure • RNA has many reactive groups that must be protected during synthesis, and then removed afterwards to generate biologically active RNA • Base deprotection is done simultaneously with cleavage from the beads • For RNA, the 2’TBDMS protecting group must also be removed • Additional deprotection step to base deprotection and cleavage from the beads Desalting and Purification • All of the deprotecting groups that were removed from the oligonucleotide need to be separated out • This can be done by large scale FPLC or HPLC • Reverse phase • Anion exchange Problems of RNA synthesis • RNA production results in three major problems from reagents used: • • Many chemicals that are used are hazardous to health and must be handled with care Large production of hazardous wastes, mainly organic solvents • • • • • • Acetonitrile Iodine THF (Tetrhydrofuran) Acetic Anhydride Trichloracetic acid Cost of large amount of reagents Problems of RNA synthesis • Reagents and their waste are a major problem. • If we could recycle and reuse these organic wastes, it would significantly reduce cost of waste reagents bought and waste removal costs. Special considerations for RNA synthesis • RNA is easily degraded by enzymes called nucleases found everywhere. • • • To keep the product stable all equipment must be cleaned of nucleases and sterile. We normally autoclave any materials that will touch RNA products RNA degraded at elevated temperatures faster • • Should be stored at -20 °C for short term Should be stored at -80 °C for long term Regulations • Good manufacturing practices (GMP) must be followed for synthesis of pharmaceuticals • • • These are the minimum requirements that must be met to assure that the products are of high quality and do not pose any risk to the consumer or public. Things to consider • • • • • Hygiene Cross contamination Consistency of manufacture Records of manufacture Recall system (in case bad batches are made) http://www.fda.gov/food/guidanceregulation/cgmp/default.ht m The Goal • The goal is to scale up a synthesis that will generate 1 gram of siRNA • Luciferase siRNA • • • A standard siRNA used to assay efficiency of gene knockdown Used in most labs that work with RNAi 5’-UCGAAGUACUCAGCGUAAGUU-3’ • In a typical 1 μmole scale synthesis we generally get about 1 milligram