HPIC 2012 LMI Energy..

advertisement

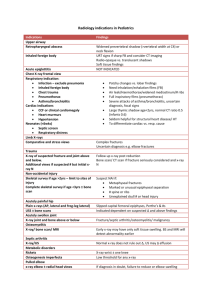

X-ray Capability for Energy Response Ludlum already has many capabilities in-house: PMT’s and plastic scintillators Circuit boards (4-layer SMT) Transformers Cables and Harnesses Welding (Alum and Steel)-Robot added 2011 Stamping, Milling, Turning Die and Mold making Plastic Injection Molding Lead Casting Wire EDM machining Alpha, Beta, Gamma, and Neutron source calibrations But not much energy response capability. Customers sometimes ask difficult questions about energy response…and not enough monoenergetic radiation sources with long half-lives exist to test well. To test both GM and scintillation detectors, we would need both uR/hr and mR/hr level sources. Sometimes, it’s just not good enough to use supplier or scientific data. As more sales go international…more people are starting to realize that there are energy differences between exposure units and dose equivalent units. “Energy-flat” in terms of exposure isn’t the same as “energy-flat” in terms of dose equivalent. And more people are asking “Why shouldn’t the US join the rest of the world in using the Sievert?” Sv/R Conversion ISO 4037-1 0.016 0.014 0.012 0.01 0.008 0.006 0.004 0.002 0 0 100 200 300 400 500 600 700 Once the decision to purchase an x-ray machine was made we needed: 1. A location 2. An appropriate x-ray machine 3. Radiation license and safety 4. Setup and Calibration • An unused 2nd floor site was chosen…with six inch concrete floor and plenty of spaceapproximately 40 feet wide by 100 feet long. When looking at x-ray systems used by other calibration facilities we found: NIST: Pantak HF320 system LANL: Pantak HF320 system ORNL: Pantak HF320 system PNNL: Pantak HF320 system Ludlum decided to get the same system. • A used (1999) Pantak HF320 system was purchased, which would give crucial energy response data in the 20-300 keV region. • An x-ray technician installed and calibrated the system onsite, and provide operational training. Ludlum RSO performed the license modification: radiation source and x-ray devices handled separately. “X-ray in Use” signs and lights installed. Door Interlocks installed downstairs-opening door causes control panel to shut beam off. Radiological survey done inside on the 1st and 2nd floors and also outside with beam at full working power and kVp. Procedures written for use, log and safety equipment established. NIST H-series filters-made with 99%+ pure materials Two filter wheels were made, each holding 8 filters. The second wheel hold HVL, used to verify the correct output spectral energy. X-ray Calibration A NIST-traceable PTW ion chamber was used to establish exposure and dose rates at approximately 16 feet. A CdTe isotope identifier (ICS-4000) was used to qualitatively see the spectra. H200 70000 60000 50000 40000 H200 30000 20000 10000 1 22 43 64 85 106 127 148 169 190 211 232 253 274 295 316 337 358 379 400 0 Clearly, we had some serious scattering issues…some additional steel shielding was added H200 with steel shield 70000 60000 50000 40000 30000 20000 10000 0 0 100 200 300 400 500 X-Ray Calibration (continued) With the steel shield in place, measurements (again with the NIST-traceable ion chamber) were taken at each of the 8 energies. The HVL filter wheel was added, and the measurements repeatedmeasurements were within 2% of half-value. Exposure and Dose Equivalent values were then taken at both the 16 and 72 ft distances to give approximately 15 mR/hr and 1 mR/hr exposure distances for GM and scintillation detectors. RESULTS: A version of the 9DP (the Ludlum pressurized ion chamber) has been developed to be energy flat to H*(10) within 20 % from 40 keV to 1.3 MeV, and this result has been verified by an independent lab. More results to follow….