Presentation

advertisement

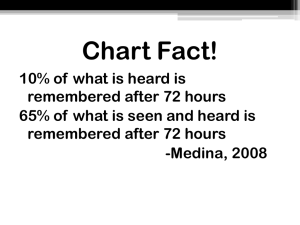

Untangling Quality Improvement Tools CAH/Small Rural Learning Community Lynne Hall s2 Flow Charts Objectives Describe the quality control and the management and planning tools used in quality improvement Explain how to use the various performance improvement tools to implement the quality management What is Quality? According to Merriam-Webster Online Dictionary, Quality is: A degree of excellence : grade A distinguishing attribute : characteristic <possesses many fine qualities> Total Quality Management (TQM) A management approach to achieve longterm success Everyone in the organization participates in improving processes, services, patient care, and the culture where they work TQM takes strong commitment from leaders in your organization Quality Tools Key: Manage what you measure ◦ What process needs work? Gather data Change process Act on data Quality Tools Key: Manage what you measure ◦ What process needs work? Gather data Change process Act on data ◦ Present data to leadership!! TOOLS AND TECHNIQUES How do I decide which improvement area needs to be address first? You can use: Flow Chart Check Sheet Pareto Chart Brainstorming Nominal Group Technique Root Cause Analysis Brainstorming Process ◦ Define the topic ◦ Ask each person for 5 ideas on the subject ◦ Give them a couple of minutes to write them down ◦ Ask for ideas and list them on a flipchart ◦ Review / clarify / combine like ideas ◦ Revisit and revise the list later in the meeting or at the next meeting Brainstorming Methods ◦ Have people use sticky notes and stick on a flipchart ◦ Take turns around the room until everyone says pass ◦ Have each team member write one idea on a sheet of paper and pass it to the next person can add to or build off other statements ◦ This is your chance to think outside the box!! Nominal Group Technique Can enhance one or more dimensions of effectiveness of decision-making groups NGT provides: ◦ more unique ideas, ◦ more balanced participation between group members, ◦ increased feelings of accomplishment, and ◦ greater satisfaction with idea quality and group efficiency Nominal Group Technique The nominal group technique is particularly useful: When some group members are much more vocal than others. When some group members think better in silence. When there is concern about some members not participating. When the group does not easily generate quantities of ideas. Nominal Group Technique The nominal group technique is particularly useful: When all or some group members are new to the team. When the issue is controversial or there is heated conflict. When there is a power-imbalance between facilitator and participants or participants: the structure of the NGT session can balance these out. Flow Chart Identifies problems and opportunities Helps define scope of process Documents a process Analyzes process for improvements Flow Chart Not toasted Get Bread Toasted? Add Peanut Butter Add Jelly Enjoy! Toasted Check Sheet Used for data collection Measure/track: ◦ ◦ ◦ ◦ Process Problems Causes Other performance factors Helps with pareto charts and other display tools (pie charts, run charts) Check Sheet Application for Check Sheets: ◦ Provides consistent data collection ◦ Identifies and defines problems / opportunities ◦ Sets priorities ◦ Identifies root causes ◦ Used for follow-up and verify results Check Sheet Getting started: ◦ ◦ ◦ ◦ ◦ ◦ ◦ Determine the data to be gathered Decide on the frequency Design a checksheet Train users Mark appropriately (checks or hashmarks) Compile results Analyze and graph data Check Sheet Making a PB & J Sandwich Data Analyst ___________ Process Step Date/Time start Date/Time Stop Pareto Chart A special type of bar chart Helps focus team on components of the problem that has the biggest impact Based on the Pareto Principle ◦ 80% of the effects we see are due to 20% of the causes The data are easy to gather They are easy to construct Easy to interpret Pareto Chart Root Cause Analysis Interdisciplinary REVIEW of the process surrounding an event (actual or near) to develop prevention strategies When – Unplanned Event (REACTIVE) What – Tool for Review Why - Review Process Steps Who – Organizational Leadership AND Frontline Caregivers How – Correct Process to Prevent Future Event FOCUS on process NOT person Appropriate use Consistent use Next: Describe the problem Check Sheet Pareto Chart Histogram Pie chart Stratification Next: Arrive at a statement that describes the problem in terms of what is specifically, where it occurs, when it happens, and its extent Check Sheet Pareto Chart Histogram Pie chart Stratification Stratification Utilizes the data to “slice and dice” ◦ What are the differences ◦ What are the similarities Consider this application anytime you want to collect data Stratification Factors Examples Who • Department • Individual • Customer Type What • Type of Complaint • Defect Category • Reason When • Month, quarter • Day of week • Time of Day Where • Region • Department • Unit Histograms Used with either continuous data or counts of attributes (discrete data) Shows distribution of the data ◦ Highs and lows Allows you to see variation in the data Helps answer questions: ◦ Is the process centered on the customer requirement ◦ Does the process miss the customer requirement ◦ Is the process skewed with unexpected points Histograms Pie Chart A circular chart that illustrates a proportion of the data Works particularly well when the slices represent 25 to 50% of the data Pie Chart What are all the possible Causes of the Problem? Check Sheet Cause & Effect Diagram Brainstorming Root Cause Analysis Failure Mode Effect Analysis Force Field Analysis What are all the possible Causes of the Problem? Check Sheet Cause & Effect Diagram Brainstorming Root Cause Analysis Failure Mode Effect Analysis Force Field Analysis Cause and Effect Diagram Also know as Fishbone Basically a structured Brainstorming Establishes categories of potential causes Gives focus to help begin process and data analysis This IS NOT a way of identifying which idea is the “culprit” Cause and Effect Diagram People Equipment Floor is wet No handrails Nurses not rounding Call lights not answered Falls Non-skid footwear Education of family Methods Failure Modes and Effects Analysis Helps anticipate problems so you can take steps to correct, reduce and eliminate (PREVENT problems or anticipated) risks Identifies ways a change in a process, product or service that may cause unintended problems Failure Modes and Effects Analysis 1. 2. 3. 4. 5. 6. Brainstorm all the potential ways the change in the process could fail List these failure modes Identify the potential cause of these failures Develop a rating scale Rate each of the factors Multiply the 3 numbers together to get the Risk Priority Number Failure Modes and Effects Analysis Multiply the 3 numbers together to get the Risk Priority Number ◦ Start with the failures that have the highest RPN’s discuss for each failure ways to eliminate the causes, the chance of it reoccurring, ect ◦ Assign responsibilities for each action identified Force Field Analysis Helps teams proactively build support and neutralize blocking factors to an impending change Application ◦ Determining solutions ◦ Identifies and removes obstacles ◦ Plans and implements a process change or solution Force Field Analysis 1. 2. 3. 4. Clarify the change or solution to be analyze Divide a flipchart page into two halves Brainstorm forces for and against the change Start with the driving forces and and identify ways to: 1. Reinforce the support 2. Make the support more visible in your plans 3. Link your solution to that support Force Field Analysis 5. Categorize the restraining forces as follows: ◦ Blocks – regulations, policies, laws ◦ Constraints – resources, budget, time ◦ Illusions – “That’s not what we have done before” 6. Identify steps to neutralize restraining forces 7. Determine which neutralizing actions are necessary and build into your plans Force Field Analysis Agree on basic cause(s) of the problem Check Sheet Pareto Chart Scatter Diagram Brainstorming Nominal Group Technique Agree on basic cause(s) of the problem Check Sheet Pareto Chart Scatter Diagram Brainstorming Nominal Group Technique Scatter Diagram Allows you to test hypothesis about the causes of the problems Uses paired data: Do these have an effect on one another? Scatter Diagram Scatter Diagram Positive correlation between the two data points Example: Positive correlation between more falls at change of shift Scatter Diagram Negative correlation between the two Example: Less falls happen during shift change Scatter Diagram Indicates a complex relationship Example: More falls happen at change of shift on Tuesdays Scatter Diagram No correlation at all between the two Example: Falls don’t depend on shift change Presenting Data to Leaders and Others Run Charts Pie Chart Bar Graphs Presenting Data to Leaders and Others Run Charts Pie Chart Bar Graphs Pareto Chart Scatter diagram Develop an effective and implementable solution and action plan Run Charts Pie Chart Bar Graphs Pareto chart Scatter Diagram Run Charts – watching performance over time Purpose: to measure and track a key input, process, or output measure over time Run Charts – watching performance over time Run charts got their name because of the practice of counting “runs” or sequences of consecutive points of either side of the median Too many or too few clusters are a signal that something special is happening within your process Graphs of data show improvement over time Tool for assessing the effectiveness of change RUN CHARTS Run charts have a variety of benefits: Help improvement teams formulate aims by depicting how well (or poorly) a process is performing ◦ Identifying problems, opportunities (trends, patterns, or output measure over time) ◦ Determining potential root cause(s) ◦ Follow-up and verification of results Provides a quick look at a process Monitoring Improvement… RUN CHARTS 1. Plot your data. 2. Find your mean or average 3. Identify runs 4. Look for Special Cause Variation 5. Note any changes made in the process Monitoring Improvement… RUN CHARTS 1. Plot your data. 2. Find your mean or average 3. Identify runs 4. Look for Special Cause Variation 5. Note any changes made in the process Implemented new fall process Monitoring Improvement: Run Chart Rules Common Cause Variation – the random variation associated with a process (No process is a straight line) Special Cause Variation – a difference in the normal process variation ◦ Six or more consecutive increasing or decreasing points ◦ Nine or more consecutive points on the same side of the median ◦ 14 or more consecutive points alternating up and down around the median Bar Graphs Used for data that is not related to one another or is not continuous Use for independent data Bar Graphs s62 Check Flow Charts Sheet Pareto Charts Check Sheet Histogram Brainstorming Nominal Group Technique What is my improvement area? Check Sheet Pareto Charts Pie Chart Root Cause Analysis Stratification Describe the Problem Check Sheet Check Sheet Cause of the Problem Root Cause Analysis Check Sheet Check Sheet References http://asq.org/learn-about-quality/totalqualitymanagement/overview/overview.html Melum, Mara Minerva and Sinioris, Marie Kuchuris; 1992;Total Quality Management http://www.emathzone.com/tutorials/basi c-statistics/scatter-diagram.html