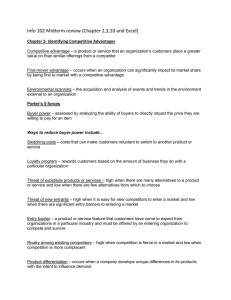

Enterprise Applications and Business Process Integration

advertisement

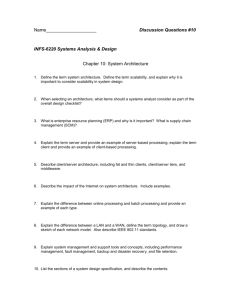

Achieving Operational Excellence and Customer Intimacy:Enterprise Applications Chapter 9 (10E) Three Systems • Our focus is on the following enterprise applications – Enterprise resource planning systems (ERP – Supply chain management systems (SCM) What Are Enterprise Systems? Enterprise System Architecture Figure 11-1 ERP • ERP systems are comprised of independent software modules with a common central database that support basic internal business processes for finance and accounting, human resources, manufacturing and production, and sales and marketing • The common database enables data to be used by multiple functions and business process for precise organizational coordination and control Business Value of ERP • A more uniform organization • More efficient operations and customer-driven business processes • Firm wide information for improved decision making Supply Chain and Supply Chain Management • A firm’s supply chain is a network of organizations and business processes for procuring raw materials, transforming into products, and distributing them to customers. Materials, information, and payments flow through the supply chain in both directions. • Supply chain management attempts to Coordinate the business processes to speed information, product, and fund flows up and down a supply chain to reduce time, redundant effort, and inventory costs A Supply Chain Figure 11-3 Parts of the Supply Chain • Upstream –includes the organization's suppliers and their suppliers and the process for managing relationships with them. • Internal supply chain – includes process for transforming the materials, components, and services furnished by suppliers into finished goods and for managing materials and inventory • Downstream – consists of the organizations and process for distributing and delivering products to the final customers Five Major SC Processes • Planning: Balancing demand and supply to meet sourcing, production, and delivery requirements • Sourcing: Procurement of goods and services needed to create a product or service • Making: Processes that transform a product into a finished state • Delivering: Processes to manage order transportation and distribution • Returning: Processes associated with product returns and post delivery customer support Logistics • Logistics concerns all factors that will have an impact on transporting the correct product/service to where it is needed on time and at the least cost. • Particularly important in the transportation of raw materials in the upstream portion of the supply chain and transportation of finished goods in the downstream portion of the supply chain. • Logistics counts for 12-14% of a manufacturer’s costs Key Supply Chain Management Processes Figure 11-4 SCM Applications (Systems) The primary goal of all supply chain management systems is to automate flow of information between company and supply chain partners. Two major types: Supply chain planning systems: Generate demand forecasts for a product (demand planning) and help develop sourcing and manufacturing plans for that product. Supply chain execution systems: Track the physical status of goods, the management of materials, warehouse and transportation operations, and financial information involving all parties. Supply Chain Planning and Execution Systems (Examples) Supply Chain Performance Measurement • Metrics for measuring supply chain performance – Fill rate (the ability to fill orders by the due date) – Average time from order to delivery – The number of days of supply in inventory – Forecast accuracy – The cycle time for sourcing and making a product Intranets and Extranets Play a Major Role in SCM Ovals represent extranet users. Figure 11-6 Advantages of Internet SCM Applications • Provide standard set of tools • Facilitate global supply chains • Reduce costs • Enable efficient customer response • Allow concurrent supply chains Demand-Driven Supply Chains • Push-based model: Production master schedules based on forecasts of demand for products, and products are “pushed” to customers • Pull-based model: Supply chain driven by actual customer orders or purchases (Dell) Push- versus Pull-Based SC Models Figure 11-7 Business Value of SCM Systems • Improved customer service and responsiveness (product availability) • Cost reduction (supply chain costs represent 75% of operating expenses for many firms; reducing sc costs can have major impact) • Cash utilization (improved cash flows) Challenges of Implementing Enterprise Systems • High total cost of ownership • Organizational change requirements • Realizing organizational goals • Seventy percent of organizations have not obtained the promised benefits of enterprise systems Vendors • Microsoft (http://www.microsoft.com/dynamics/ax/product/supplyc hain.mspx ) • SAP (SAP United States - Business Management Software | Enterprise Application Integration) • Oracle (http://www.oracle.com/applications/procurement/intro.h tml) • JDA (http://www.jda.com/solutions/strategic-supplydemand-solutions-overview.html ) Why Do Enterprise Projects Fail So Often? • Enterprise systems software requires people to adopt new work methods • People often don’t agree that the Enterprise systems way of doing things is better than existing processes • Either people resist or force IT to customize Enterprise systems • Customization makes the software unstable and harder to maintain • The mistake companies make is assuming that changing people's habits will be easier than customizing the software. There is a delicate balance between these two choices. • Extensive collaboration and planning across functional areas and between firms. • Huge education and training needs.