Commercial Kictchens Case Study Dalhousie

advertisement

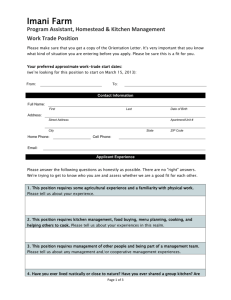

Commercial Kitchens Dalhousie University Case Study With the financial support: Commercial Kitchens – How it started • Proposed project to students in Campus as a Living Laboratory course – (Jan. – April 2011) • How much energy and water is used in one Dal kitchen? Power (kW) 35.00 30.00 25.00 20.00 15.00 10.00 5.00 0.00 04/01/2011… 04/01/2011… 04/01/2011… 04/02/2011… 04/02/2011… 04/02/2011… 04/02/2011… 04/02/2011… 04/03/2011… 04/03/2011… 04/03/2011… 04/03/2011… 04/04/2011… 04/04/2011… 04/04/2011… 04/04/2011… 04/04/2011… 04/05/2011… 04/05/2011… 04/05/2011… 04/05/2011… 04/05/2011… 04/06/2011… 04/06/2011… Answer • A lot of energy and water is used in kitchens. • Everything is much larger than a home kitchen, staff are cooking long hours, and for a lot of people. SUB - Kitchen Energy Consumption Series1 3 Kitchens & Dining Hall – Sustainability target area • Due to the volume of food production, commercialsized foodservice facilities are more energy and wateruse intensive than office and classroom spaces. In addition, foodservices utilize large quantities of food and material inputs and impact waste diversion rates of these resources. 4 Commercial Kitchen Project: 2011-2013 Basic equipment auditing (Nov 2011March 2012) Honors Thesis – Kitchen Employee Sustainabili ty Behaviours (Sept. 2012March 2013) Provincial -Wide Workshop (April 2012) Consultant’ s Report (Nov. 2011 – Feb. 2012 Detailed equipment audit and refrigerator compressors (May 2012March 2013) Major kitchen upgrade (Jan 2012 – ongoing) Installing of ENERGY STAR equipment (Aug 2012 – ongoing) Developing a kitchen education program, more upgrades and equipment, ventilation designs (Jan 2012 – ongoing) 5 Commercial Kitchen Workshop and Kitchen walks Auditing • We have eight commercial kitchens and a number of smaller food serving areas! • Consultant’s report – high level recommendations - no detail equipment audits. • There are hundreds of pieces of equipment 7 Method 1. Reviewed existing information such as ENERGY STAR® Guide for Commercial Kitchens and Food Services Technology Centre – Self Site Survey 2. Worked with Dal Food Services to create an inventory sheet with all equipment 3. Expanded inventory sheet to include other information from tools such as ENERGY STAR® calculator Method 4. Created an audit sheet for student auditors 5. Metered older equipment that had no published energy data – used watt meter, Watt’s UP power meter, and fluke 1750 meter 6. Created a detailed report with findings, GHG emissions, energy, and costs savings 9 Findings • No speed drives on hoods, no metal sides, and some equipment outside the hoods – impacting ventilation and creating noise • Some low-flow pre-rinse but others not • Old equipment in some areas –fryers, ice machines, refrigeration • Many old Walk-in fridge/freezer fan motors/compressors • Dishwasher and pre-rinse station – older • Leaky taps • Frost build up – door insulation strip – needed fixing • Opportunity to switch to natural gas • Behavioural opportunities • Redesign opportunity • Lighting upgrade potential, timers in walk-ins • Waste bin arrangement, education, and signs opportunities Immediate Actions • Replaced old Bakers Oven with new ENERGY STAR ovens – Projected 20% energy savings • Replaced older dishwasher with new ENERGY STAR dishwasher 14 Actions • Completed auditing report, thesis, refrigeration audit • Major retrofit of largest kitchen to address all recommendations include major investment in new equipment from fryers, to fridges, ovens, … Actions • Follow-up audits to confirm work is done is resulting in need for more education and regular preventative maintenance checks. – Low flow pre-rinse head was initially leaking. 16 Conclusion Costs • Studies and student auditing • Thesis work • Time Benefits • $ cost, GHG, energy, waste and water savings identified – kitchen equipment, water, lighting, walk-in fridgefreezer compressors/motors, VSD for hoods and metal siding, waste management, pre-rinse station water, water leaks, water left on, flow heads • Sustainability leadership • Education – Team building 17 Next Steps • Finish developing education program with Food Services. • Preventative maintenance checks for kitchens – every two months by utility service staff. • Finish ventilation study designs (outside contractor). • Finance more equipment and other kitchen system upgrades. $300,000 In ENERGY STAR kitchen equipment invested this year. 18