续流二极管:铝层去除之后看到的溶解痕迹

advertisement

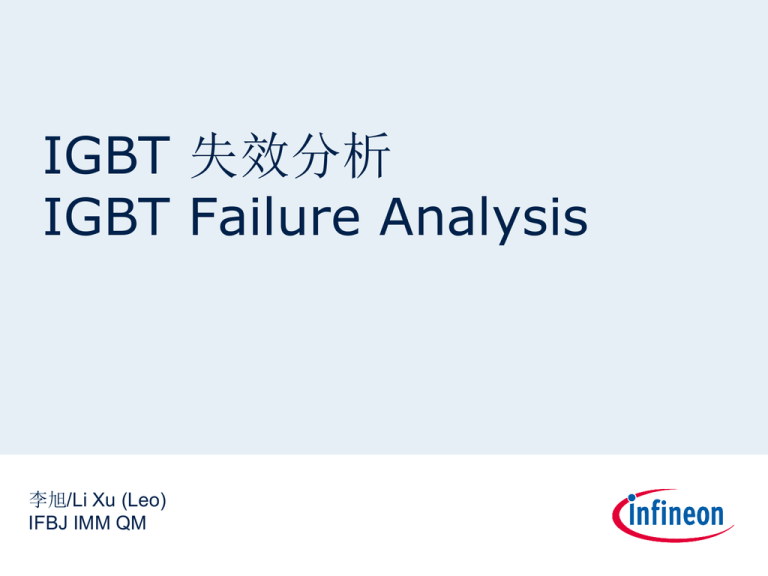

IGBT 失效分析 IGBT Failure Analysis 李旭/Li Xu (Leo) IFBJ IMM QM 失效分析 Introduction 失效分析的目的是为了维护良好的客户关系,改进产品质量,提高竞争力 Failure Analysis is to support customers more effectively during problem solving, and to feedback from field/application for Infineon’s further product development, yield enhancements 失效分析的分析内容是寻找故障点的位置,表征故障现象,确定导致故障 的根本原因 Failure Analysis is the localization and characterization of defects 失效分析需要采取多种分析手段,直到找到故障的根本原因,或者直到穷 尽所能采取的分析手段 It is necessary to continue until you find the cause or exhaust all tests doing so. 失效分析的挑战:分析周期,分析成本与准确性之间的平衡 Challenge: Do it as fast and accurately as possible 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT Item 分析方法与分析流程 1 分析客户反馈的信息 Customer Information 2 外观检查 Visual Inspection 无损检测 Nondestructive 3 电性能分析 ELECTRICAL VERIFICATION 无损检测 Nondestructive 4 X射线检测 X-ray Inspection 无损检测 Nondestructive 5 超声波显微镜检测 Ultrasonic Microscope 无损检测 Nondestructive 6 去除塑料外壳 Opening Housing/Lid Removal 破坏性检测 Destructive 7 去除硅胶,去除绝缘钝化层 Gel Removal and Polyimide Removal 破坏性检测 Destructive 8 光学显微镜检测 Optical Microscope 无损检测 Nondestructive 9 液晶热点成像分析 FAULT ISOLATION by Liquid Crystal Analysis 10 高端仪器深入分析 Advanced FAULT ISOLATION – Delayering, Photon Emission Microscope, SEM, Cross-section, FIB 11 分析、总结失效机理 ,确定失效的根本原因 FAILURE MECHANISMS- SUMMARY and REVIEW 注解Remarks 破坏性检测 Destructive 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 1.分析客户反馈的信息 Customer Information 反馈信息表 FAR Form IGBT应用的条件 客户观测的故障信息 是否已知故障 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 2.外观检查 Visual Inspection 是否有导热硅脂残留? Thermal grease found? 是否已安装PCB板? PCB mounted? 塑料外壳是否被破坏? Housing damaged? 是否有烟雾残留物? Smoke residues found? 基板是否已被破坏?Base plate damaged? 模块是否爆炸? Module exploded? 模块是否被打开? Module already opened? 管脚是否有焊锡残留,是否弯曲,是否脱落? Solder at pins? Bent pins? Missing pins? 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 3.电性能分析 ELECTRICAL VERIFICATION Programmable Curve Tracer 可编程特性曲线测量 高压直流电源 High Voltage DC Supply 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 4. X射线检测 X-ray Inspection 无损检测 Nondestructive 检测空焊 IGBT Chip soldering, system soldering 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 5.超声波显微镜检测 Ultrasonic Microscope 无损检测 Nondestructive 检测焊层的分层,衬底裂痕 Chip soldering delamination, substrate crack 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 6.去除塑料外壳 Opening Housing/Lid Removal 破坏性检测 Destructive 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 7.去除硅胶,去除绝缘钝化层 Gel Removal and Polyimide Removal 破坏性检测 Destructive 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 8.光学显微镜检测 Optical Microscope 无损检测 Nondestructive Leica, Olympus 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 9.液晶热点成像分析 FAULT ISOLATION by Liquid Crystal Analysis 起偏器、检偏器 与光学显微镜、curve tracer或者测试机配合使用 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 10.高端仪器分析-深入芯片内部微米级、纳米级结构 Advanced FAULT ISOLATION Delayering 去层 Photon Emission Microscope 光子发射显微镜 SEM and EDX 电子显微镜及特征X光能谱分析 Cross-section 剖面分析 FIB 聚焦离子束 TEM 透射电子显微镜 SIMS 二次离子质谱 失效分析的分析方法与分析流程 FAILURE ANALYSIS-Step By Step For IGBT 11.分析、总结失效机理 ,确定失效的根本原因 FAILURE MECHANISMS- SUMMARY and REVIEW 通常存在不止一个故障点 There maybe more than one defect 哪一个故障点才是失效的根本原因 Which defect is the root cause 总结失效机理并撰写分析报告 Summary and prepare report IGBT常见失效现象 IBGT common failures IGBT 集电极-发射极过压 Collector-Emitter Overvoltage pulse on IGBT IGBT 门极-发射极过压 IGBT 过电流脉冲 Gate-Emitter overvoltage IGBT Overcurrent pulse on IGBT 续流二极管正向过电流,例如浪涌电流 FWD too high current in forward direction RBSOA超出安全工作区 RBSOA exceedance for IGBT IGBT过温 Over temperature IGBT 震动产生的故障 Vibration defects 陶瓷衬底裂痕(不恰当的安装过程) Cracked ceramic (inappropriate mounting) IGBT常见失效现象 IBGT common failures IGBT 集电极-发射极过压 Collector-Emitter Overvoltage pulse on IGBT IGBT常见失效现象 IBGT common failures IGBT 门极-发射极过压 Gate-Emitter overvoltage IGBT 集成在门极上的电阻有熔化的现象 Molten areas at the integrated gate resistors IGBT常见失效现象 IBGT common failures IGBT 过电流脉冲 Overcurrent pulse on IGBT IGBT常见失效现象 IBGT common failures 续流二极管正向过电流,例如浪涌电流 FWD too high current in forward direction, for example surge current I IGBT常见失效现象 IBGT common failures 续流二极管正向过电流,例如浪涌电流 FWD too high current in forward direction, for example surge current II Al layer 铝层 Al removed 铝层去除之后 Typical melting ring around the bond wire 通常会在绑定线的位置周围有熔化现象 IGBT常见失效现象 IBGT common failures 续流二极管正向过电流,例如浪涌电流 FWD too high current in forward direction, for example surge current III Melting tracks on a diode chip (Al removed) 续流二极管:铝层去除之 后看到的溶解痕迹 IGBT常见失效现象 IBGT common failures RBSOA超安全工作区 RBSOA exceedance for IGBT – turning off an over current I Deep molten spot in the cell field IGBT常见失效现象 IBGT common failures RBSOA超安全工作区 RBSOA exceedance for IGBT – turning off an over current II – Cross Section Cross section: deep molten spot 剖面分析:贯穿芯片的熔洞 IGBT常见失效现象 IBGT common failures RBSOA超安全工作区RBSOA exceedance for IGBT – turning off an over current III Deep molten spot with secondary damages IGBT常见失效现象 IBGT common failures IGBT过温 Over temperature IGBT (Al and solder affected) Solder below the IGBT is poured out 底部的焊锡熔化溢出 Large areas of the aluminum layer are molten, typical beads 大面积的铝层熔化,同时 存在熔化后冷凝而产生的 小铝珠 IGBT常见失效现象 IBGT common failures IGBT过温 Over temperature IGBT (imide layer affected) Bubbles in the imide在涂 层上有过温产生的气泡 IGBT常见失效现象 IBGT common failures 震动产生的故障 Vibration defects Good bond wires 正常的绑定线 Typical vibration defect: three bond wires cracked one after another. The last wire fused due to the high current. 典型的震动导致的故障点:三根绑定线断 裂,最后一根绑定线由于过流而熔断 IGBT常见失效现象 IBGT common failures 震动产生的故障 Vibration defects with high power modules Crack at the internal collector terminal 在集电极端子上的裂痕 IGBT常见失效现象 IBGT common failures 陶瓷衬底裂痕(不恰当的安装过程)Cracked ceramic (inappropriate mounting) I Crack partially visible around a mounting hole 裂痕环绕安装镙孔 IGBT常见失效现象 IBGT common failures 陶瓷衬底裂痕(不恰当的安装过程) Cracked ceramic (inappropriate mounting) II Ultrasonic image of the crack 超声波显微镜观察到的裂痕