Novel Composite Materials & Structures for Blast Mitigation

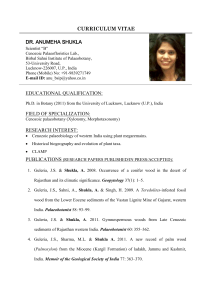

advertisement

Novel Composite Materials & Structures for Blast Mitigation: Arun Shukla, URI Dynamic PhotoMechanics Laboratory Purpose/ Relevance: Conduct fundamental experiments to elucidate physical mechanisms responsible for damage in novel composite materials & structures subjected to extreme environments associated with blast & fragment loading, thus leading to new more efficient materials & structures. Innovation: Highly controlled experiments with real time measurements at extremely high loading rates to give full field load-deformation & damage information at materials & structural level. DPML team at URI has unique capabilities and long experience for such experimentation. This Year outcome: (a); A comprehensive series of experiments were conducted under controlled blast loading conditions using the shock tube facility to understand damage mechanisms in structural glass panels. A new type of glass panel was designed which restraints the shattered pieces of glass from flying off and causing damage and injuries (b); Numerical expressions were developed to understand the energy redistribution associated with shock loading (c); Experiments on the effect of curvature on blast mitigation in metallic panels were initiated. Long-range impact:. Design of new multi-functional materials and structures with excellent blast mitigation capabilities to safeguard human life and property. Next Year: The work on understanding the effect of curvature on blast mitigation properties of a structure will be continued with metals and then extended to composites. Efforts will also be made to further understand performance of sandwich glass composites. Novel Composite Materials & Structures for Blast Mitigation: Publications Dynamic PhotoMechanics Laboratory E. Wang, N Gardner and A. Shukla, “The blast resistance of sandwich composites with stepwise graded cores”, International Journal of Solid and Structures, 46, 3492-3502, 2009. E. Wang and A. Shukla, “Analytical and Experimental Evaluation of Energies during Shock Wave Loading”, International Journal of Impact Engineering, 37, 1188-1196, 2010. M. Jackson and A. Shukla, “Performance of sandwich composites subjected to sequential impact and air blast loading”, Composites: Part B (2010), doi:10.1016/j.compositesb.2010.09.005. E. Wang, N. Gardner and A. Shukla, “Experimental study on the performance of sandwich composites with stepwise graded cores subjected to a shock wave loading”, SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Albuquerque, New Mexico , June 1-4, 2009. N. Gardner, “Blast performance of sandwich composites with discretely layered core”, SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Student Paper Competition, Albuquerque, New Mexico , June 1-4, 2009. S.A. Tekalur, E. Wang, M. Jackson and A. Shukla, “Failure Behavior and energy absorption of sandwich composites under dynamic loading”, SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Albuquerque, New Mexico , June 1-4, 2009. E. Wang and A. Shukla, “Evaluation of Incident, Reflected and Deformation Energies During Blast Experiments”, SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Albuquerque, New Mexico, June 1-4, 2009. N. Gardner and A. Shukla, “The Blast Response of Sandwich Composites with a Functionally Graded Core”, SEM Annual Conference and Exposition, Indianapolis, Indiana, June 7-10, 2010. N. Gardner and A. Shukla, “The Blast Response of Sandwich Composites With a Functionally Graded Core and Polyurea Interlayer”, SEM Annual Conference and Exposition, Indianapolis, Indiana, June 7-10, 2010. E. Wang and A. Shukla, “The Blast Response of Sandwich Composites with In-Plane Pre-Loading”. SEM Annual Conference and Exposition, Indianapolis, Indiana, June 7-10, 2010. P. Kumar and A. Shukla, “Blast Loading response of Glass Panels”, SEM Annual Conference and Exposition, Indianapolis, Indiana, June 7-10, 2010. E. Wang and A. Shukla, “Core Deformation of Sandwich Composites under Blast Loading”, SEM Annual Conference and Exposition, Indianapolis, Indiana, June 7-10, 2010. Publications, Students Supported and Industry Collaborations Dynamic PhotoMechanics Laboratory E. Wang and A. Shukla, “Blast Response of Sandwich Composites using Digital Image Correlation Technique”, 9th International Conference on Sandwich Structures (ICSS9), Caltech, Pasadena, California, June 14 - 16, 2010. E. Wang and A. Shukla, “Performance of Pre-Stressed Sandwich Composites Subjected to Shock Wave Loading”, 14th International Conference on Experimental Mechanics (ICEM 14), Poitiers, FRANCE July 4-9, 2010. P. Kumar and A. Shukla, “Dynamic Response of Glass Panels Subjected to Shock Loading”, IMPLAST 2010, SEM Fall Conference, Providence, October 12-14, 2010. E. Wang and A. Shukla, “Energy and Impulse Evaluation during a Shock Tube Experiment”, IMPLAST 2010, SEM Fall Conference, Providence, October 12-14, 2010. N. Gardner and A. Shukla, “The Blast Resistance of Sandwich Composites with a Functionally Graded Core and Polyurea Interlayer”, IMPLAST 2010, SEM Fall Conference, Providence, October 12-14, 2010. Four Papers are being submitted for the upcoming 2011 SEM Conference and 3 Papers are under preparation for Journal publication. Graduate Students Supported 1. Puneet Kumar 2. Matthew Jackson 3. Erheng Wang 4. Jefferson Wright Undergraduate Students Supported 1. Daniel Gracia 2. Alexander Escher 3. Andrew Krystnewicz Consulting with industry 1. 3 Tex, 109 Mackenan Dr., Cary, NC 27511 2. XO-Armor, 7812 Melrose Street, Houston, TX 77022 3. Webcore, 8821 Washington Church Road, Miamisburg, OH 45342 4. TPI Composites, Inc., 373 Market Street, Warren, RI 02885 Novel Composite Materials & Structures for Blast Mitigation: Experimental Methods Shock Tube Facility (at URI) Driver Section Dynamic PhotoMechanics Laboratory Driven Section Sandwich Composite Specimen Shock Tube 3D DIC System with High Speed Cameras Diaphragm 2D DIC System with High Speed Camera DIC System(at URI) Strain at 600 microseconds Deflection at 600 microseconds