Quality Tools for Process Improvement

advertisement

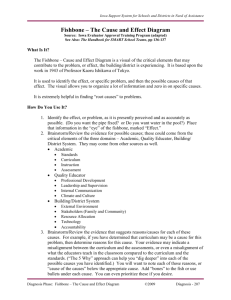

QUALITY TOOLS FOR PROCESS IMPROVEMENT PDCA/PDSA PDCA/PDSA PDCA Plan. Do. Check. Act PDSA Plan. Do. Study. Act Cyclic approach Managing a project Problem solving process Increasing your knowledge with each cycle Recording results 3 Emphasizes understanding results not recording them PDSA CYCLE FOR LEARNING AND IMPROVEMENT Objective, questions and predictions (why) Plan to carry out the cycle (who, what, where, when) Plan What changes are to be made? Next cycle? Act Continuous Improvement Do Carry out the plan Document problems and unexpected observations Begin analysis of the data Study Complete the analysis of the data to predictions Summarize what was learned 4 THE MODEL FOR IMPROVEMENT What are we trying to accomplish? When you combine these three questions with the PDSA cycle, you get the Model for Improvement. How will we know that a change is an improvement? What change can we make the will result in improvement? P A D S 5 ROOT CAUSE ANALYSIS ROOT CAUSE ANALYSIS – 5 WHY PROCESS • The first “Why?” • This is the top reason behind the problem • Answer that question • The second “Why?”, third “Why?” and so on • This should follow the same idea • Continue until you have drilled down to the root of the problem or root cause of your issue 7 WHY IS THE FRENCH TOAST BURNT? • Why is the French toast burnt? • The flame on the stove was too hot • Why was the flame too high? • Staff didn’t know how to work the stove • Why didn’t the staff know how to work the stove? • The staff was never instructed in use of stove • Why wasn’t the staff instructed in the use of the stove? • It is not in the job description training • Why is it not in the job description training? • French toast is a new item on the menu 8 SUPERSTORM SANDY EXAMPLE • Why were there not enough oxygen concentrators? • There were not enough working electrical outlets • Why were there not enough working electrical outlets? • Some outlets were cracked or did not work • Why were the outlets cracked or not working? • The staff did not check/test the outlets • Why didn’t the staff check the outlets? • It is not in the preparation checklist • Why is it not on the preparation checklist? • We never had a problem before 9 FISHBONE DIAGRAM FISHBONE DIAGRAM (ISHIKAWA DIAGRAM) • Represents cause and effect • Effect forms the head of the fish • Potential causes form the skeleton • Structured way to represent contributors to problems 11 FISHBONE DIAGRAM CONTINUED Environment System Facilities s Patients 12 Materials Manpower FISHBONE DIAGRAM Reasons to use a Fishbone Diagram: • Organizes causes/potential causes • Helps the team discuss the issues • Provides framework to organize issues • Visual presentation by areas • Living document Limitations of the Fishbone Diagram: • Based on opinion • Lost energy spent on “potential” causes • Comes down to a democratic vote 13 PROCESS MAPPING PROCESS MAPPING FOR CONTINUOUS QUALITY IMPROVEMENT • Simple method • Highlights wasteful steps in your process • Maps out the actual processes • Not processes in procedures and manuals 15 PROCESS MAPPING SYMBOLS Oval shows input to start process or output at end of process There is usually only one arrow out of an activity box. If there is more you may need a decision diamond. Box or rectangle shows task or activity performed in process Yes Diamond shows places in process where yes/no question is asked or decision is required 16 N o Oval shows input to start process or output at end of process Process Mapping Source: wikipedia/commons/9/91/Proposed_Patient_Appointment_Procedure.png. PROCESS MAPPING CONTINUED Now What? • Discuss “reality” with the leadership • Use recommendations to create a new map • Change one thing- not everything • Test the new process map • Gather key information to support the change • Saves time, supplies, staff time • Increased accuracy, consistency • Better definition of task= improved teamwork • Discuss updating policies and procedures 18 REFERENCES • Knoth, J., Miller, J. (2014). Quality Tools for Process Improvement. Healthcare Quality Strategies. Inc.