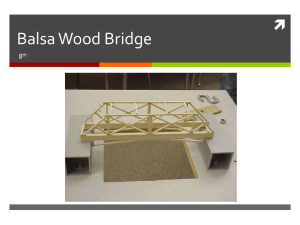

Truss Bridges

advertisement

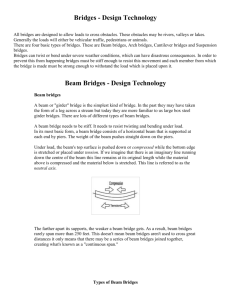

Characteristics of Three Bridge Types Important Terms: Squeezing (Compression) Compression is a force that squeezes a material together. When a material is in compression, it tends to become shorter. Stretching (Tension) Tension is a force that stretches a material apart. When a material is in tension, it tends to become longer. See a demonstration of these forces! 1. Truss Bridges • Consist of vertical, lower horizontal & diagonal members • Typically composed of triangular units that are connected at joints Characteristics of Truss Bridges • The “truss” is usually a triangular unit. • It creates a very rigid structure & one that transfers the load from a single point to a much wider area • Truss bridges are usually made from a series of straight, steel bars. Forces Acting on Truss Bridges The larger the height is compared to the span, the greater its strength Every bar in this bridge experiences either a pushing or pulling force. The bars rarely bend. Pros & Cons of Truss Bridges • Economical to construct • Spans longer distances than beam bridges • Ability to support weight relies on the strength of the joints 2. Beam Bridges • Also known as a “girder” bridge •Simplest type of bridge Characteristics of Beam Bridges • Made up of a horizontal beam supported at each end by piers. • The weight of the beam pushes straight down on the piers. • The farther apart its piers, the weaker the beam becomes. • These bridges rarely span more than 250 feet. Under load, the beam's top surface is pushed down or compressed while the bottom edge is stretched or placed under tension When something pushes down on the beam the beam bends. Its top edge is pushed together, and its bottom edge is pulled apart. Pros & Cons of Beam Bridges • Needs to resist twisting and bending under load • Simple design: Less expensive and requires little maintenance • Only suitable for short spans (about thirty to six hundred feet) 3. Suspension Bridges • Cables are hooked on vertical suspenders that support the load Characteristics of Suspension Bridges • These bridges can span 2,000 to 7,000 feet -- much farther than any other type of bridge! • Most suspension bridges have a truss system beneath the roadway to resist bending and twisting. “Cable-stayed” suspension • In all suspension bridges, the roadway hangs from massive steel cables, which are draped over two towers and secured into solid concrete blocks, called anchorages, on both ends of the bridge. • Cars push down on the roadway, but because the roadway is suspended, the cables transfer the load into compression in the two towers. The two towers support most of the bridge's weight. Early suspension bridges did not account for wind Pros & Cons of Suspension Bridges • Allows for longer spans than other bridge types • Requires stable ground for the “anchorages” at either end • May withstand earthquakes better than other bridge types • Aesthetically more beautiful than other two types of bridge • Lots of bridge photos on the quiz link