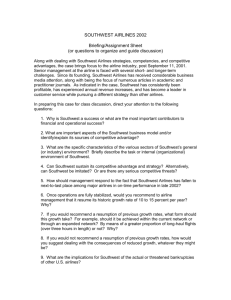

MGT 3501 - Operations Management Fall 2005

advertisement

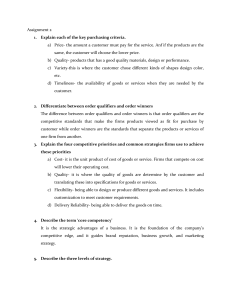

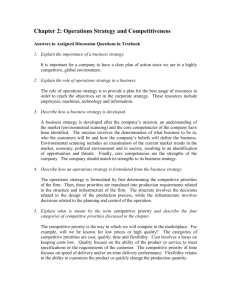

Operations Strategy What is Operations Strategy ? Operations Strategy is concerned with setting broad policies and plans for using firm resources to best support long-term competitive strategy. Operations strategy needs to support overall corporate strategy. Competitive Dimensions 1. Cost Make it cheap 2. Quality (product & process) Make it good 3. Delivery Speed Make it fast 4. Delivery Reliability Deliver as promised 5. Demand Management Handle Changes in Demand 6. Variety Make more than one type 7. Innovation First mover advantage Competitive Dimensions All of the competitive dimensions are important… why not try to excel along every one? Competitive Dimensions and Trade-offs Trade-offs Trade-offs: Decisions that arise because of the inability of processes to excel simultaneously across all competitive dimensions. Which Dimensions Should Be the Focus? Order winners: Criterion that differentiates one firm from another. Examples: Cost (Southwest Airlines), service quality (Ritz-Carlton Hotels), Flexibility (Dell) Order qualifier: Criterion that permits the firm’s products to even be considered for purchase. Example: basic quality necessary to be considered a good car (consumer reports). Example Southwest Airlines overall corporate strategy is to “serve price- and convenience-sensitive customers.” Corporate Strategy Finance Strategy Marketing Strategy Operations Strategy Developing an Operations Strategy 1. Segment the market according to the product group. Example: High-end vs. low-end consumers 2. Identify (a) product requirements, (b) demand patterns, (c) profit margins. Example: many components, seasonal, low demand, high profit margin. 3. Determine the order winners and order qualifiers. Example: delivery speed (winner), cost (qualifier) 4. Convert order winners into specific performance requirements. Example: Must sell at or below $600 Developing an Operations Strategy The next step is to analyze the process level… 1. Define the complexity and volume of your product/service. 2. Define whether you offer few specific products/services or highly customized products/services. 3. Determine product design, process design, supply chain design, supplier relations, capacity management plan & technology choice Examples Examples • Southwest Operations – low cost – Point-to-point between midsize cities & secondary airports in large cities – 15-min gate turnaround – No meals – No assigned seats – No interline baggage checking – No premium classes of service – Automated gate ticketing – Standardized fleet of aircraft Measuring whether the strategy is working Productivity is a common measure for how well a company is utilizing its resources Outputs Productivity Inputs • Productivity measurement shows how well the company performs for a given level of inputs. • Partial measures may give more specific details about performance. Output Output Output or or Labor Captial Material Productivity Measurement Example: Consider the following case. A bank has net output (income) of $500,000. The bank employs 40,000 people. The partial labor productivity is 500,000 / 40,000 = 12.5 What does this tell you? Productivity Measurement The productivity index is a relative measure. It has to be compared with something else: 1. Benchmarking. 2. Changes over time. The important thing is to be consistent in measurement! Examples Examples • Walmart – low cost – High investment into IT to manage inventory, analyze point of sales data, track shipments, etc. – Management by data – Scale – Negotiation power with suppliers Summary and Conclusions 1. Firms must trade-off competitive dimensions when defining operations strategy. 2. This can be done by defining order winners and order qualifiers. 3. A Productivity Index can measure the relative performance between firms (or products, SBU’s, etc)