Metallurgy

advertisement

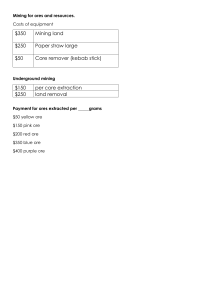

Metallurgy The extraction of metals from their ores, heat treatments and the production of alloys Production of metals Mining Concentration Metal extraction Mining Five main types of mining: Open cast mining Underground mining Open pit mining Dredging Solution mining Open cast mining Underground mining Open pit mining Dredging Solution mining Ore concentration Also called ore dressing, the aim is to increase the amount of metal in each tonne of ore. The ore is crushed then ground and concentrated, the following methods may be used: Gravity concentration Flotation Magnetic separation Amalgamation Gravity concentration Some ores are heavier than the waste. The ore is shaken by a jolting box, or similar, while wet. Particles will separate into layers depending on weight, the metal may be removed as a layer. Flotation The fine particles of ore are swirled around in large tanks with air blown in and flotation agents added. The particles attach to the bubbles and float to the surface where the froth is skimmed off. Magnetic seperation In the seperation of ores that have magnetic properties, the ore is ground and passed over a rotating drum. The drum has a magnet inside it which holds the magnetic ore particles as the waste falls outside the screen. The ore held on the drum can be released or scraped off. Magnetic seperation http://www.youtube.com/watch?v=XZjPr8WZtas Metal extraction The process of extracting metals from concentrates: Pyrometallurgy – furnace heat is used with a reducing agent (iron uses coke) and a flux to produce metal and slag waste. Hydrometallurgy – leaching dissolves ore in a solvent and then electrolysis is used to separate the metal. Thermo-electrometallurgy. Aluminium can be extracted from salt or mineral mixtures by electrolysis. It uses a lot of electricity making it an expensive process. Blister copper is refined by electrolysis.