File

advertisement

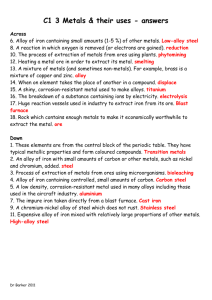

Metallurgy The extraction of metals from their ores and the production of pure metals and alloys Production of metals Mining Most metals are found as ions in ionic compounds mixed with other components like rock (called the ore) Gold, Platinum, Silver and sometimes Copper are found as elements (pure atomic form) Metallurgy- process of extracting and processing the metal from the ore Concentration- uses various physical and chemical processes Metal extraction- uses various physical and chemical processes Example of Ores Malachite Formula Cu2CO3(OH)2 Bauxite: bauxite can include: gibbsite Al(OH)3, boehmite AlO(OH) and diaspore, AlO(OH). Hematite Fe2O3 Mining Five main types of mining: Open cast mining Underground mining Open pit mining Dredging Solution mining Open cast mining Underground mining Open pit mining Dredging Solution mining Ore concentration Also called ore dressing, the aim is to increase the amount of metal in each tonne of ore. The ore is crushed then ground and concentrated, the following methods may be used: Gravity concentration Flotation Magnetic separation Gravity concentration Some ores are heavier than the waste. The ore is shaken by a jolting box, or similar, while wet. Particles will separate into layers depending on weight, the metal may be removed as a layer. Gold panning is an example of gravity concentration Flotation The fine particles of ore are swirled around in large tanks with air blown in and flotation agents added. The particles attach to the bubbles and float to the surface where the froth is skimmed off. Copper and lead are separated this way. Magnetic seperation In the seperation of ores that have magnetic properties, the ore is ground and passed over a rotating drum. The drum has a magnet inside it which holds the magnetic ore particles as the waste falls outside the screen. The ore held on the drum can be released or scraped off. Iron is separated this way. Magnetic separation http://www.youtube.com/watch?v=XZjPr8WZtas Metal extraction- the ionic compound that has a metal ion needs have a chemical process to change the metal ion into a metal atom (like a single displacement rxn) The process of extracting metals from concentrates: Smelting – furnace heat is used with a reducing agent (iron uses coke, mostly carbon) and strong continual air flow to produce metal and slag waste. Many times these are synthesis, decomposition and single displacement reactions Steps involved in purifying iron using a blast furnace- Smelting Oxygen in the air reacts with coke (C solid) to give carbon dioxide: synthesis The limestone breaks down to form carbon dioxide: (decomposition) Carbon dioxide produced in 1 + 2 react with more coke to produce carbon monoxide: (synthesis) The carbon monoxide reduces the iron in the ore to give molten iron: (single displacement) The limestone from 2, reacts with the sand to form slag (calcium silicate): (synthesis) Both the slag and iron are drained from the bottom of the furnace. (iron is at the very bottom then slag above it…due to density of each) The slag is mainly used to build roads. The iron whilst molten is poured into moulds and left to solidify - this is called cast iron and is used to make railings and storage tanks. About 90% pure The rest of the iron is used to make steel. (Higher purity needed) Blast furnace Further refining may be necessary for the mineral Electrolysis Electricity is used to purify the metal from the mineral Two different metals are plunged in an aqueous solution of the ionic compound (example CuSO4 (aq)) The ion acquires the necessary electrons from the electricity to change back to the atom. (Cu+2 + 2 e- → Cu (s)) The metal atom accumulates on one of the metals immersed in the solution…99% pure This process is scaled up industrially to produce sheets of copper Canadian Mint recognized all over the world for its 4 nine gold….99.9999% gold After refining…it is now the metal at high conc. (90+%) Common Alloys The new purified metals are sometimes remixed in specific percent ratios to make alloys…these are mixtures and not compounds Stainless steel is mostly iron with about 10% chromium Bronze= mostly copper and some tin Brass= mostly copper and some zinc Pewter=mostly tin and some copper White gold= 90%gold, 10% nickel Steel= iron and 2% carbon Impact on the environment + (jobs, metals) - disruption of the land from the mining process itself…like dust and rubble as a result of surface mining are released into the atmosphere - accidental release of dangerous chemicals like cyanide (used to purify gold) - release of acidic oxides from the smelting process (Sudbury example…new technologies addressing this issue) Impact - accidents to trap miners - mine tailings are acidic…caused by newly exposed rock and iron pyrite (FeS, fool’s gold) reacting with oxygen and water and can sometimes be accidentally released in the ground water and harm aquatic ecosystems - Tailings in tar sands have thunderous shot gun sounds every minute to dissuade ducks from landing on the acidic ponds Alberta Tar Sands Alberta Tar Sands https://www.youtube.com/watch?v=61X4IQqn md0&feature=player_detailpage https://www.youtube.com/watch?feature=play er_detailpage&v=Sjia7BsP4Bw