Assembling introduction

advertisement

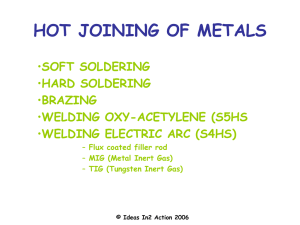

EAT – E-learning Electronics Assembling Technology E-learning Program 1. Introduction: The electronics assembly process flow Department of Electronics Technology Budapest University of Technology and Economics BME-ETT Elect2eat Team: www.ett.bme.hu Zsolt Illyefalvi-Vitéz, PhD Olivér Krammer János Pinkola, dr et al 1 Chapters 1. Introduction: The electronics assembly process flow Components and Printed Circuit Boards 2. Components used for electronics assembly 3. Printed wiring boards 4. Surface finishes used on printed wiring boards Assembling Technologies 5. Soldering techniques and solder joint design principles 6. Solder paste stencil printing 7. Component placement methods and process sequences 8. Reflow soldering, reflow ovens and temperature profiling 9. Wave soldering and thermal profiles 10. Selective soldering 11. Hand soldering and assembly repair Inspection, Test and Quality Management 12. In-line inspection and test techniques 13. In-circuit and functional test 14. Total Quality Management 2 Electronics assembly variations – Through-Hole Technology (THT) Electronics Assembly is the process of attaching component leads or terminations to lands or pads of conductors on a circuit board and then join them by soldering. There are two primary categories of components and assemblies; through hole and surface mount. At through-hole technology (THT), component leads are inserted through holes in the printed wiring board (PWB); and soldered to the lands on its other side. A TH component is the DIL IC (dual-in-line integrated circuit), whose leads usually have a pitch of 2,54 mm (0,1”) 3 SMT – Surface Mounting Technology Terminations of surface mount devices (SMDs) are attached to the board pads by soldering to make both electrical and mechanical connections. In some cases conductive adhesive joints are used. Process steps: 1. Solder paste application 2. Adhesive application for wave soldering 3. Components placement 4. Adhesive curing by heat or UV light 5. Reflow or Wave Soldering 6. Board cleaning 4 Electronics assembly combinations 5 The assembly line for reflow soldering 6 Types of discrete components by function and assembling Active components: amplify the electric signal, need energy source, built from semiconductor materials Passive components: amplify the electric signal, do not need energy source, built on insulating materials Assembling types of components: Through Hole components 7 Surface Mount passive components and integrated circuits Thick film chip resistor SOIC: Small Outline Integrated Circuit Multilayer ceramic capacitor PLCC: QFP: Plastic Leaded Chip Carrier Quad Flat Pack 8 Surface Mount ICs with high lead count QFP (Quad Flat Pack) Very high number of leads (up to 1000) are located at all the four sides of the package Pitch minimum is 0,3 mm FC–PBGA (Flip Chip – Plastic Ball Grid Array 9 Substrates: Types of Printed Wiring Boards In an electronic assembly the substrate or circuit board supports the components mechanically, and interconnects their terminations electrically. Printed wiring board is the general term for completely processed printed wiring configurations, including single-sided, double-sided and multilayer boards with rigid, flexible and rigid-flex base materials. For circuit cards and modules the rigid printed wiring boards are used, while flexible and rigid-flex printed wirings are popular for the interconnection of cards placed in different position in equipment or of different units. Rigid printed wiring board Flexible printed wiring board 10 Printed Wiring Boards Printed wiring board (PWB) is a substrate, which is made up of an insulating board with copper foil tracks on it. The components are fixed to the PWB and connected to the conductive copper tracks by soldering. In general, the base material of a PWB is a copper clad laminate, and the conductive pattern is prepared from the copper foil by subtractive technology, that is by the combination of photolithography and chemical etching. Multilayer boards are made by the lamination of single boards and adhesive layers. The patterns of the different layers are connected with plated holes (or vias). 11 Assembling process steps defined by soldering 12 Mixed assembly, applying glue: combinations of reflow and wave soldering 13 Soldering Solder joints use some metal alloy material to fasten and electrically contact conductive parts, like soldering pads and component leads. Applying heat and some flux, the surfaces of the parts are wetted by the melted alloy, and the joint is formed when the solder re-solidifies. The soldering alloy has a – preferable eutectic – melting point (MP), lower than to injure the parts. Most popular alloys are: • lead-free SAC alloy, e.g.: 95.5Sn3.8Ag0.7Cu; MP = 217 oC • conventional leaded alloy: 63% Sn 37% Pb; MP = 183 oC The flux helps the wetting process. Flux types are as follows: • Resin (most popular): non-corrosive, soluble in alcohol, needs cleaning • RMA = Rosin Mildly Activated: resin or rosin activated by acid • no-clean flux: transparent, insulating, no need for cleaning • water soluble organics. Two types of soldering are in use in mass production, namely: • reflow soldering when the solder is applied in paste form and then melted (reflowed) to make the joints; • wave soldering, where the solder and heat source is a solder wave. 14 Solder paste application Solder pastes are formulated to be printable mixtures, and they are applied to the pads of the board using stencil printing. 15 Placement of SM components for reflow soldering Surface mount assembly consists of three basic processes: • solder paste application, • component placement, and • reflow soldering. 16 SMT pick-and-place head and machine Placement to optically recognized pad positions. Polarity checking and simple measurements during placement. Efficiency up to 60.000 SMD / hour. 17 Component placement failures inspected optically - Component falls down from the nozzle - Misplacement and rotational offset (see figures) - Wrong polarity - Billboard (component lays on the edge) - Face down component - Component placed on another component - Injured component 18 Reflow soldering Reflow soldering is usually carried out in • a convection type or • a combined IR heated hot-air (or N2) furnace. Conveyor belt type ovens are applied in both cases. 19 Wave Soldering: automated soldering of through-hole and surface mounted assemblies -shaped wave (oxide-free) foamed or sprayed flux pump pump Flux application Pre-heating 80…120 ºC Solder wave 240…260 ºC PWB-s are transported through the wave soldering equipment by a conveyor belt, which has a transport speed of: 1,3..1,5 m/min). Both the heat and the solder are provided by the solder wave. 20 Integrated Repair Station Repair stations are used to correct and repair recognized soldering failures, with functions as follows: Visualization of soldering failures Integrated shuttle Marking of component positions Pictures of the originally detected failures Storage of error pictures Reporting of failure class 21 Fabrication of the LEADOUT board by lead-free soldering – an example In the following slides some details of the fabrication of the LEADOUT demonstrator board is presented. 1. Equipment and data of assembly with photos - stencil printing & stencil design - assembly – component placement - reflow soldering 2. Fabrication problems and their effects - offset of stencil aperture - solder paste misprint - imperfect component placement - paste misprint and smearing 22 Stencil Printing & Stencil Design Thieme TES/S-25 stencil printer features: Printing speed: 20…140 mm/s Pressure: 10…60 N, angle: 45…90º Settings during experiment: Printing speed: 400 mm/s Pressure: 55 N, angle: 45 º Stencil: Laser-cut 150 µm thick Stainless steel Inverse home plate apertures for Surface Mount Components 23 LEADOUT ”lead-free” demonstrator after stencil printing 24 Assembly – Component Placement TWS laser quadra features: Automatic pick & place 2 nozzles Laser centering 0402 smallest component 0,4 mm smallest pitch size Testboard used to determine proper parameters for component placement and soldering 25 The LEADOUT demonstrator after component placement 26 Reflow Soldering ESSEMTECH R006 reflow oven: Convection with infra heating Nitrogen atmosphere can be used Settings: Preheat: 190 °C (in air) Soak: 200 °C, 160 s Reflow: 220 °C, 20 s Green: 3x3 cm copper area Red: 0603 chip R Blue: air 27 The LEADOUT demonstrator after reflow soldering 28 Monitoring the Assembling – Process Examples Effect of solder paste misprint: wetting corrected misprinting After stencil printing After reflow soldering 29 Monitoring the Assembling – Process Examples Effect of the offset of stencil aperture: wetting pulled back the solder and the SMD After stencil printing After reflow soldering 30 Monitoring the Assembling – Process Examples Imperfect component placement #1: reflow and wetting pulled back the SMD After component placement After reflow soldering 31 Monitoring the Assembling – Process Examples Imperfect component placement #2: reflow and wetting pulled back the SMD After component placement After reflow soldering 32 Monitoring the Assembling – Process Examples Imperfect component placement #3: reflow and wetting pulled back the SMD After component placement After reflow soldering 33 Monitoring the Assembling – Process Examples Paste misprint and smearing: resulted in solder ball formation After component placement After reflow soldering 34 Monitoring the Assembling – Process Examples Paste misprint and smearing: resulted in solder bead formation After component placement After reflow soldering 35