Forklift Training

Safety Training Presentations

FORKLIFT OPERATOR SAFETY TRAINING

2

Forklift Operator Training

• Who needs forklift training?

– Anyone who operates a forklift

• Who must conduct the training?

– A knowledgeable trainer

• Why is training necessary?

– Forklifts pose many hazards

• Approx. 100 deaths and 38,000 injuries/year

• Most Common accidents:

– Tip over

– Struck by lift or struck by load

3

Forklift Safety Hazards

• Forklifts are very heavy

– Average automobile - 1,000 - 2,000 lbs.

– Average forklift - 4,000 - 8,000 lbs.

• Loads can be heavy

– Too heavy to lift by hand

• Forklifts or their loads can be unstable

– Forklifts can roll over easily

– Loads can fall off forks or cause roll over

4

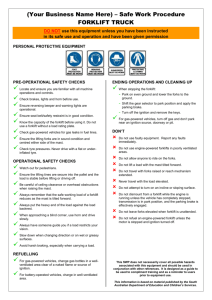

Pre-Use Inspections

• Inspect forklift before each use

– Don’t know condition left in by last user

– Not inspecting the forklift prior to use could lead to a hazardous situation or cause serious damage to the forklift and/or the load

5

• Brakes

• Steering

• Horn

• Lights

• Oil

• Coolant

• Battery/LP Tank

• Hoist

Pre-Use Checklist

• Forks

• Engine/Drive Motor

• Tires

• Misc.

– Cage

– Seat belt

– General overall condition of the forklift

6

Pre-Use Inspection - Lift Mechanisms

• Inspect mast for damage

– Broken or cracked weld point

• Make sure roller tracks are greased and free to travel

• Inspect forks

– Cracks on ends, along blades or at heels

– Make sure not bent

• Check hydraulic lines and fluid levels

7

Pre-Use Inspection - Lift Mechanisms

• Inspect all lift and tilt cylinders

– Leaks

– Mounting hardware

• Inspect tires

– Excessive wear

– Proper inflation (if not solid rubber)

8

Propane Tank Inspection

• Inspect cylinder for damage

• Cracks and broken weld points

• Inspect

• Valves, nozzles and hoses

• Be aware of flammability

• Three ways to detect leaks

• listen for gas escaping

• smell odor

• look for frost on the coupling

9

Changing Propane Tanks

• No smoking!

• Shut off cylinder valve before turning off forklift to reduce pressure in the fuel line

– Liquid propane is approx. -40 degrees

• Wear heavy duty rubber gloves

• Wear safety glasses

• Make sure pressure relief valve points straight up when replacing the tank

10

Battery Charging

• Inspect batteries for worn parts and cables

• Beware of acid

– No smoking

– Wear faceshield, goggles, apron, rubber gloves

– Only add water after charging

• Make sure charger is off before disconnecting the battery

• Remove all jewelry

• Use hoist or roller system when replacing

11

Capacity Plates

• Must be on all forklifts

– If missing or illegible, replace

• Information found on capacity plates

– Model #

– Max load weight

– Max lift height

– Serial #

– Manufacturer information

12

Starting the Forklift

• Apply the foot brake

• Shift gears to neutral

• Turn the key

• Check gauges and indicators

• Check controls, steering and brakes for smooth operation

13

Operating the Forklift

• Know locations and functions of all controls and gauges

• Be aware of what is going on around you

• Be aware of potential problems with the forklift

• Be sure path of travel is free from hazards

• Traveling speed in doors should not be any faster than a quick walking pace

14

Handling and Moving Loads

• Check the Capacity Plate to be sure the forklift can handle the load

• Check the load for weight and stability

– If load is not marked

• Contact distributor/shipper of the load

• Lift the load 1-2 inches to test the stability of the rear wheels and the forklift

• If the forklift struggles, set the load down and if possible break load into smaller, more manageable loads

15

Stability Triangle

16

Stability Triangle

• The closer the center of gravity (CG) is to line BC the more stable the forklift is

• The closer the CG is to lines AB or AC the more unstable the forklift becomes

• If the CG ever goes outside the stability triangle, the forklift can tip

– Loads too heavy or offset

– Taking corner too fast

– Traveling surface is not level

17

Fulcrum Point

• The front wheels of the forklift are the fulcrum point

– The rear of the forklift has counter weights to help off set the weight of the load

• Unloaded forklift is unstable - all the weight is in the rear

– When the forks are loaded the weight of the forklift and load are more evenly balanced

• Loaded forklift is more stable

– When the load out weighs the counter weight the forklift can tip forward when the load is raised

18

Tipping Forklift

• What should you do?

– Must be wearing seatbelt

• Will keep you from falling out of caged area

– Hold tightly to steering wheel with both hands

• Keep hands and arms inside caged area

– Plant feet flat on floor and press down

• Keeps body stable and keeps legs in caged area

– Lean in opposite direction

19

Handling and Moving Loads

• Picking up load

– Approach the load straight on with the forks in the travel position

– Stop when the fork tips are approx. 1 foot away from the load

– Level forks and drive slowly forward until load is against backrest

– Lift the load high enough to clear what is under it

20

Handling and Moving Loads

• Picking up load (cont.)

– Look over both shoulders to make sure you are clear and slowly back out one foot

• Sound horn before backing if can’t clearly see behind you

– Slowly tilt mast back to stabilize the load

21

Handling and Moving Loads

• Setting down the load

– Drive to location, square up to load area and stop about one foot away

– Level the forks and slowly drive forward

– Lower the load

– Tilt the forks slightly forward

– Look over your shoulders and back straight out until the forks clear the load

22

Stacking and Unstacking

• Lifting a load

– Approach the load slowly with the forks in the travel position

– Stop approx. one foot away from the load and raise forks to correct height

– Level forks and drive forward until load is flush against backrest

23

Stacking and Unstacking

• Lifting a load (Cont.)

– Lift high enough to clear the bottom load, look over both shoulders to see if clear to back and slowly back straight out

– After clearing top of stack, stop and lower mast to travel position

– Tilt forks back

– Proceed to destination

24

Stacking and Unstacking

• Stacking a load

– Approach placement area slowly and square

– Stop about one foot away and lift mast high enough to clear the placement area

– Move forward slowly until the load is square over the stack

– Level the forks and lower the mast until the load is resting on the stack

– Slowly back straight out

25

Stacking and Unstacking

• Additional tips

– Never lift a load while moving

– Stop completely before raising the mast

– Make sure the top load is squarely stacked on bottom load

– Always approach and leave the load area slowly

– Always look over shoulders before backing up

26

Driving with a Load

• Travel with load tilted slightly back for stability

• Travel with the load at the proper height

• 4-6 Inches at fork tips

• 2 Inches at heels

• Drive in control

• Drive in reverse if you cannot see over the load

27

Driving on Inclines - Ramp/Slope

• Always drive with the heavier or less stable end of the forklift pointing up the incline

– If the forklift is loaded (heavier/less stable in front)

• Drive forward up the incline with the load

• Drive in reverse coming down the incline with the load pointed up the incline

– If the forklift is not loaded (heavier in rear)

• Drive forward down the ramp

• Drive in reverse going up the ramp

28

Stopped Forklift

• When Parked or unattended

– Forks flat on ground

– Turn off engine

– Set parking brake

– Do not block:

• Exits

• Emergency equipment

• Signs or postings

29

Pedestrians

• Pedestrians have the right of way

– Slow down at intersections

– Look before backing

– Use horn when coming around blind corners and at blind intersections

– Check mirrors at intersections if they are present in workplace

• Pedestrians must be cautious in areas where forklifts may be operating

30

Conclusion

• Forklifts are more hazardous than most people usually perceive them to be

• Pre-use inspections must be performed before each shift

• It is important to understand how the load will affect the stability of the forklift

• The operator must always be on the look out for hazards and pedestrians

31