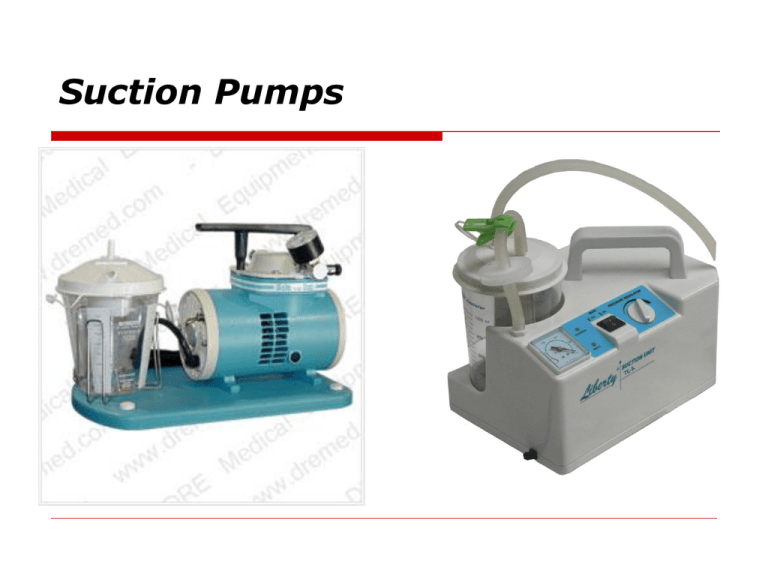

Lecture 6 Suction Pumps

advertisement

Suction Pumps Topics Principles of operation Diagrams Applications Types of suction pumps Safety Operation Preventive maintenance Common failure modes Basic troubleshooting Principles of Operation Suction generated using a pump Pump powered by electrical motor or foot pedal Pump moves piston up and down Piston attached to air tight diaphragm Pulls air in from collection container through one-way valve to reduce pressure Reduced pressure draws fluid from patient via tubing Fluid remains in bottle until disposal Valve prevents fluid from passing into motor Motor speed determines suction strength Principles of Operation Connection Tubing Diagrams Shell Air Intake Barb Vacuum Gauge Patient Tubing Input Power Switch Power Source Indicator Collection Container Battery Condition Indicators Collection Container Holder Vacuum Power Indicator Power Cord Vacuum Regulator Power Input/Electrical Input Receptacle Diagrams Motor Air intake from collection container Air intake to pump Vacuum gauge Air exhaust from Pump Grounding ribbon Vacuum regulator Electrical input receptacle Grounding plate Diagrams Power Distribution Board Power Supply Battery Applications Used to remove fluid from body cavities Removal of: Surgical fluids in the operative field Mucosal secretions Used in patients with compromised swallowing or coughing Safety ALWAYS use PPE when working with suction pumps Pumps come in direct contact with bodily fluids Wash hands immediately after removing gloves Never fill the collection container more than 75% full Liquid will enter pump Before using, read the owner's manual Operation Position the unit close to patient Plug into AC power (do not use extension cords) Attach first suction tubing from pump suction control to collection bottle outlet Attach second suction tubing to collection bottle inlet Operation Check all components and connections for tight fit Turn suction pump on (on/off electrical switch) Crimp tubing coming from the collection bottle inlet In order to test full range of suction Adjust suction to desired level while observing vacuum gauge Initiate suction procedure Preventive Maintenance Daily Clean filters Clean air vents Disinfect jars, tubing, other components that come into contact w/ patient fluids between each use in solution of water, detergent, and disinfectant Change bacteria filter if wet or discolored Check collection bottle/jar for cracks, chips, and other damage Make sure there is a sufficient supply of bacterial filters Check that float valve moves freely 1-3 months Clean or replace air intake filter Clean brushes on motors as necessary Inspect power cord and plug Ensure vacuum works over full range of suction pressures if there is a control/knob Verify that overflow valve (float valve) works properly when container is filled with water Grounding resistance between chassis and ground pin should not exceed 0.5 ohms Common Failures Most common: Clogs, Leaks, Motor Failure Leaks: Tube blockage or kink Missing/damaged parts: Tube leak Jar/lid leak (bad O-ring, possibly) Bad motor Bad power supply No collection bottle No filter Clogged bacterial filter Float valve closes air pathway with full collection jar Insufficient pressure/suction Ventilation grill obstructed Suction control knob is set to a low setting Diaphragm needs cleaning or replacing Brushes need cleaning Motor needs lubrication Basic Troubleshooting Basic Troubleshooting