Salt_water_system

advertisement

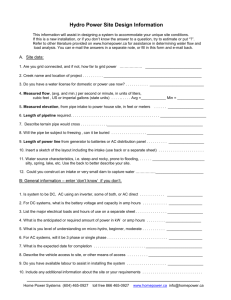

Salt water system Function • • • • • • • • Hot Domestic service Cold Domestic service Fire main Sprinkler system Deck Wash Ballast system Engine and Equipment cooling Special services (for example Watermaking etc) “The word manifold may come from the Old English word manigfeald (from the Anglo-Saxon manig [many] and feald [fold]) and refers to the folding together of multiple inputs and outputs.” Rule 1 In each section the water is drawn from a skin fitting placed on the hull • as low as possible • in a position which will not affect or be effected by any other intake or outlet Rule 2 • skin fitting with a built in “Screw Lift Valve” to simplify installation • If it is not possible to fit a combined Sea cock and skin fitting then a screw lift valve should be placed in the suction line as near to the skin fitting as possible Often a manifold system is adopted • Individual line valves are fitted for system isolation ideally as close as possible to the Suction Manifolds • sometimes additional local valves may be fitted adjacent to a particular piece of equipment for ease of operation • The supply valves, if possible, should be quick action types (1/4 turn full on to fully off) although due to the pressure involved with larger systems they may well have to be conventional “screw down” types. Sea Water Intakes • With sea water systems the main problem is usually air entrainment which creates a “false cavitation” in the pump with its consequential corrosion problems • This problem is created by the design/placement of the intake • The problem is also increased with a vessel’s speed and also on vessels which do a large amount of astern running All intake boxes should be designed to assist the de—aeration of the water and remove turbulence. • Upward buoyancy of small air bubbles is not great and, therefore, in most intake boxes, the bubbles have only sufficient time to travel a few inches in a vertical direction. • With fast liquid velocities the bubbles may even be carried downwards • The intake grid should be of longitudinal slots and not holes or vertical slots which are sometimes installed in error • Intake grid of holes - much of the area is lost, due to turbulence. If horizontal slots had been used only a small area loss would have occurred, due to the turbulence at each end of the slots only; • The flow is upwards to the suction pipe and all the air travels into the system. • The intake grid is in the middle of the intake box, and so is the suction pipe. Due to the forward motion, astern conditions are sacrificial, the general liquid direction is aft/inboard, and it therefore has to swirl forward to enter the suction pipe incurring losses. • Relative position of grill suction pipe; • Longitudinal baffle and submerged suction pipe to create rise and fall in flow to assist de— aeration; • Box top—angled past longitudinal baffle to avoid flow picking up any separate air; • De—aeration pipe is in a non—flow area; • Steady baffle—difficult to place correctly but worthwhile and should face general flow direction. Scoop Intakes • There is usually less choice in where a scoop intake can be positioned compared with a normal intake but, again, the position should be such that the entry of aeration from beneath the vessel must be minimized • Since the effectiveness of the scoop increases rapidly with the speed of the vessel (scoop head varies as the square of the vessel’s speed), the use of a main circulating pump is still necessary for low speed manoeuvring. Salt Water Flow Rates The choice of water speed in the system will depend upon • the main circulating pump characteristics • the materials to be chosen for the pipework Salt Water Flow Rates • • • • • Owing to the severe effect of corrosion/erosion which sea water has on materials the following maximum design water speeds are given for guidance: Galvanized steel 3m/sec Copper 1m/sec Aluminium brass 3m/sec 90/10 Copper—nickel 3.5m/sec 70/30 Copper—nickel 4m/sec Q V=----S Strainers • The simplest strainer consists of a box with a removable lid in which a flat perforated, • Perforation sizes vary according to duty and manufacture but are invariably in the range 3—12 mm. • Such strainers will be found close to sea water suction valves and immediately before bilge valves (strum boxes) basket strainers • These consist of a cylindrical container in which a perforated metal or wire basket is suspended Single strainer for high pressure water Or oil service Single strainer for low pressure water or oil service