Presentation (Winter)

advertisement

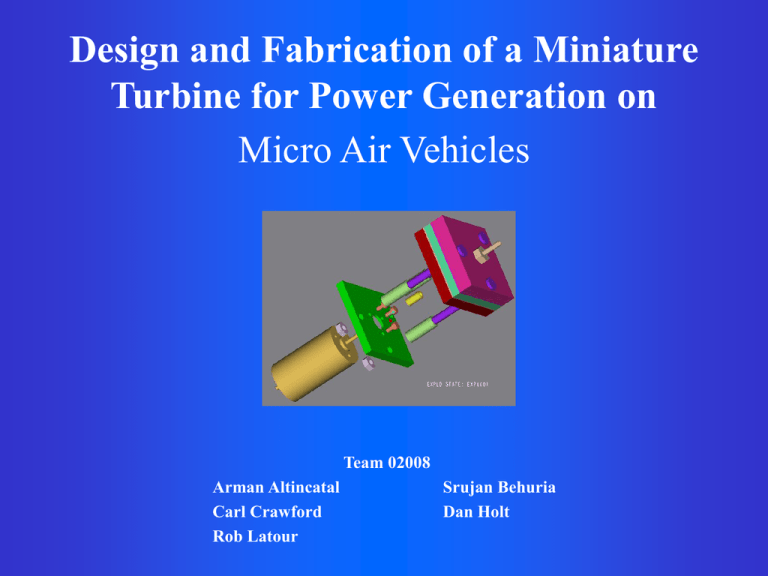

Design and Fabrication of a Miniature Turbine for Power Generation on Micro Air Vehicles Team 02008 Arman Altincatal Carl Crawford Rob Latour Srujan Behuria Dan Holt Overview • Project Motivation and Goals • Concept Development / Feasibility Assessment • Project Objectives and Specifications • Analysis • Future Plans Current Problem • The weight of batteries is prohibitive for Micro Air Vehicles (MAVs) • Current Batteries Black Widow by Aerovironment – More than 50% of the weight of vehicle – Less instrumentation can be attached to MAV MicroTurbines: a Possible Alternative • Much greater power to weight ratio • Microturbines are being developed at a number of schools MIT’s Micro Turbine Impeller Project Scope • • • • • • • Proof of Concept 10 mm impeller Spins at 50,000 rpm Powered by compressed nitrogen (air) Produces 5-15 watts of electrical power Can be scaled down to MEMS size Distribution of Work Concept Development and Feasibility • Used Brainstorming Methods to Generate Ideas • After voting, 4 concepts remained: – – – – Multiple Jets Control Scheme Air to Cool Generator Light Weight Materials • Rated the concept feasibility based on technical, economic, market, schedule, and performance factors Multiple-Jet Concept • Multiple inlets to increase the torque • Total mass-flow must increase • Rotational balance must be achieved • The feasibility of the design is above baseline model (single jet) • The concept is approved by the design team and will be implemented Control System Concept Development • Terminal Characteristics of a DC Generator • Loading the Generator • Effect of Reduced Shaft Speed • Constant Generated Voltage Desired • Achieving Generator Shaft Speed Control – Variable Solenoid – Variable Nozzle • Control Scheme Feasibility – Above Baseline Aspects – Below Baseline Aspects • Feasibility Assessment Results T1 3 P4 T2 2 P3 E1 1 P2 0 E2 P1 M1 S2 M2 S1 Exhaust Air Used to Cool Generator • Cooling Generator – Higher Speeds – More Power • Heat Sink • Friction in Turbine – Reduces Cooling Efficiency • Concept compares well with baseline in most aspects of feasibility • Deferred Decision Light Weight Materials • Use of light materials – MAV’s • Strength, Cost, Manufacturability • Many options available – Steel, Silicon Carbide, Plastics – Aluminum (Best option) • Team will pursue light weight materials based on feasibility assessment Design Objectives and Specifications Objectives Specifications • Electrical Power • Production of torque • Generator should run for at least 15 minutes • Generator should be reusable • Design for MAV’S • 5 watts • Minimum torque should be .021 oz-in • Blades should spin at minimum of 50,000 rpm • Generator Temp. should be less than 125°C Performance Specifications • • • • Produce at least 5 watts of electrical power Blades should spin at minimum of 50,000 rpm Generator Temp. should be less than 125°C Minimum torque should be .021 oz-in Flow Passages • Two jet design • Air fitting mounted axially to turbine • Identical Passages – Length, Turns – Inlet Conditions • Head loss calculations – Major, Minor – 7.89% pressure loss (Pinlet =100psi) • Assumptions – Air is an ideal gas – Fully developed, turbulent flow Nozzle Analysis • • • • • Uncontoured converging nozzle design Nozzle machined into the casing plate Inlet - 1.58 mm X 1.25 mm Outlet - 0.7 mm X 1.25 mm Control volume analysis done for various inlet temperatures and pressures • For Pinlet = 100 psi and Tinlet = 275 K – Mass flow = 0.0048 kg/s – Reaction force = 0.258 lbf • Assumptions – – – – Steady State Ideal Gas Isentropic Choked Flow Computational Fluid Dynamics • Pre-Processing - Geometry - Mesh • Post-Processing - 2D and 3D Flow Solver - Model Solution • Equations used to solve the model: - Conservation of Mass - Conservation of Energy - Transport Equations (Navier Stokes) Iterative Steps to Optimize Geometry 1 2 3 4 CFD Analysis of Miniature Air Turbine • • • Flow performance - Moving Reference Frame (MRF) - Geometry modifications Torque due to forces on the blades Validate CFD with experimental results Dynamic Pressure Contours (Pa) - Limited references available in this area • Designing a tool to optimize future models Static Pressure Contours (Pa) Generation • Electrical Scope of Miniature Turbine Project • Generator Selection • Synchronous Generator • Separately Excited DC Generator • Shunt Generator • Series Generator • Permanent Magnet DC Motor (PMDC) Brushed PMDC Motor • Voltage Regulation Faulhaber Miniature Drive Systems Brushless PMDC Motor Structural Design Posts Inlet Face Plate Turbine Casing Generator Casing Bolts Coupling Future Plans • Fabrication • Dental Turbine • Experimentation to Validate Objectives and Specifications – Torque, RPM, Exit Temp., Power – Efficiency