Boiler Operation

advertisement

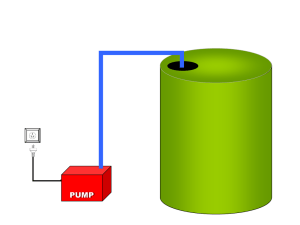

INSTRUCTOR: ROBERT A. MCLAUGHLIN ZAILI THEO ZHAO 1 INTRODUCE & PUMPS 07:34 POWER EQUIPMENT POWER EQUIPMENT EG234 Lecture/A - Power Equipment Lab Credits: 2.00 An introduction to marine and stationary power plant systems and equipment through study, inspection, and maintenance applications. course supports the marine license program requirements to meet the Standards for Training, Certification and Watchkeeping (STCW). The course may have embedded assessment requirements that must be completed in addition to the class requirements. 07:34 The 2 TEXTBOOKS & REFERENCES TEXTBOOKS Principles of Naval Engineering. NAVPERS 10788-B NAVEDTRA 12960. U.S. Navy, 1992. Power Equipment Lab Project Manual, 07:34 Seventh Edition, 2002. REFERENCES: Control Valves & Actuators. Modern Marine Engineers Manual. Instrument Society of America: Industrial Training Corp. 1989. Hunt, Everett C. Vol. 1, Third Edition, 1999. Control Valve Handbook: Fisher Controls Co. Second Edition, 1977. 3 OBJECTIVE Student will be exposed to 07:34 the theory of auxiliary power equipment systems used in maritime & power plants. making accurate system drawing of components. the importance of measurement principles and quality repair standards. basic safety concerns and lockout/tagout procedures typical in industry. Students will demonstrate an understanding the auxiliary power systems. The ability to create accurate system drawings. Accurate measurement standards and basic repair techniques. understanding of basic safety procedures. 4 TOPICS Week 1: Fluid Pumps Multistage Compressor, Internals & Demonstration Week 6: Automated Valves & Regulators Valves, Packing & Steam Traps Week 5: Air Compressors & Air Handling Systems Temperature & Fluid Flow Measurements Week 4: Piping, Valves, Fittings and Steam Traps Tubular/Disc Purifiers Week 3: Measurement Temperature, Fluid Flow and Level Centrifugal, Recip. & Gear, Type Pumps Week 2: Lube Oil Purifications & L.O. Management 07:34 Air Operated Control Valves & Self-contained Reducers Week 7: Heat Exchangers, Purpose, Mediums, Flow Heat Transfer/Exchanger Demo 5 TOPICS (CONT.) Week 8: Distilling Plants Auxiliary Turbine Operations Week 13: High Pressure Fittings Isolation & Reactivation Week 12: Auxiliary Turbines & Controls Shaft Seal Assembly Week 11: Tagout & Safety Procedures Shaft Alignment Model Training Week 10: Shaft Seal Systems Gland Seals, Mechanical Seals & Packing Glands - Industrial Packing, Desalination Equip. & Reverse Osmosis Demonstration Week 9: Machinery Alignment & Couplings 07:34 Boiler Gage Glass, Replacement/Torque Procedures Week 14: Industry Presentation Guest Lecture Quality Assurance 6 EVALUATION & EXAM Assignments and Class Participation 25% Quizzes (6) 50% Final Comprehensive Exam 25% There will be six quizzes given throughout the semester. An exam will be given every other week throughout the semester, and there will also be a comprehensive final exam of the course at the end of the semester. An excused absence from a quiz will require the quiz to be made up within one week of the original schedule. Failure to complete the makeup will result in a zero for the missed quiz. 07:34 7 WEEK 1 PUMP LEARNING OBJECTIVES Develop an understanding of how pumps function Identify various pump types, applications and limitations Define pumping principles and terms common to pumps, such as: pressure head, Static head, velocity head and friction head Introduce the formula for determining the capacity and discharge pressure of a reciprocating pump, PLAN = PLAN 07:34 8 PUMP FUNCTION Pumps are used to add energy to liquids to produce flow or increase pressure. They function to Circulate liquids and with most Fuel delivery systems Transfer – move liquids from one area to another Cooling systems Heating systems Supply 07:34 Fuel oil transfer Pressurize systems Domestic water systems Hydraulic systems 9 FORCE- PRESSURE –AREA RELATIONSHIPS is defined as force per unit area 07:34 Pressure for us in this class we will use pounds per square inch (psi. How much pressure is there at the bottom of a 33 ft column of water? (p = h) 62.4 lb in 2 lb 33 ft / 144 ( ) 14 . 33 ft 3 ft in 2 .433 psi per ft for water. 10 FORCE- PRESSURE –AREA RELATIONSHIPS principle pressure is transmitted equally and undiminished in all directions of a contained system. 07:34 Pascal’s 11 SUCTION AND DISCHARGE All pumps move fluid(water, oil, molten metal, sludge) from one place to another by: Pushing Pulling Throwing Squeezing or some combination of all of these 07:34 12 POWER END AND FLUID END All pumps have: A power end 07:34 Pistons on reciprocating pumps Motors on centrifugal pumps Electric / Hydraulic / Air Steam turbine or internal combustion engine Fluid end or the pumping end Pumps develop no energy of their own. They transform energy from some external source to potential and kinetic energy. We measure the input source of power in horsepower (HP) 13 KINETIC PUMP The major types of pumps are kinetic(Centrifugal), positive displacement, and eductors: 07:34 Kinetic pump (centrifugal) which uses a spinning rotor (impeller or propeller) to increase kinetic energy or velocity head and pressure of the pumped fluid and pressure of the pumped liquid. Centrifugal pumps may be operated with the discharge closed; however, the friction of the fluid churning within the casing will generate heat. It is not a good idea to operate for long periods of time with the discharge closed. Systems, like boiler feedwater systems, which have regulators that may limit or stop flow for short periods of time, will have recirculation lines. A recirculation line connects the pump discharge to the suction source, and should open when the discharge flow decreases. 14 TYPES OF CENTRIFUGAL PUMPS Volute Pump In the volute pump, which is also the pump casing, the impeller discharges into a volute, which is a gradually widening spiral channel in the pump casing. The volute converts the liquid velocity created by the impeller to pressure. 07:34 15 TYPES OF CENTRIFUGAL PUMPS Diffuser Pump In the diffuser pump the liquid leaving the impeller is first slowed by the stationary diffuser ring that surrounds the impeller. The diffuser consists of gradually widening passages through which the liquid dumps into the volute of the pump. Since both the diffuser and the volute reduce the velocity of the liquid, there is almost a complete conversion of the kinetic energy (velocity head) to potential energy (pressure) 07:34 16 IMPELLERS The impellers spin at a high rate of speed and must be carefully machined and balance to avoid vibration. 07:34 Closed impellers have side walls or shrouds on both sides of the vanes. A semi-closed impeller has a wall on one side of the vanes; the other side is open An open impeller has no side walls, the vanes are attached directly to the hub. Hub- a solid center area that has a hole through it. The pump shaft extends through the hub 17 EYE OF THE IMPELLER The eye is the area the liquid enters into the impeller. 07:34 Liquid is led to the eye through internal passages in the pump casing An impeller can have a single suction eye, or it can have two suction eyes; one on each side of the impeller. A single eye impeller creates thrust axially in a direction opposite of the liquid entering the eye. In the double suction impeller the thrust is counter acted Water enters the eye in an axial direction, and leaves the impeller in a radial direction. 18 MULTY STAGE, SHAFT SEAL & High pressures, centrifugal pumps can have multiple impellers mounted on one shaft. 07:34 The discharge from the first stage enters the second stage impeller eye. The area where the shaft passes through the casing must be sealed. Packing or with mechanical seals. A packed pump will have a lantern ring or seal cage installed. The seal cage is a place where discharge pressure liquid can be introduced into the stuffing box to lubricate, seal and cool the packing. 19 CAPACITY capacity is expressed as volumetric flow rate & discharge pressure 07:34 Pump The capacity of a centrifugal pump can be increased by doing one of two things Increase the speed of the pump Increase the size of the impeller 20 POSITIVE DISPLACEMENT PUMP 07:34 A movable element forces liquid through the pumps casing. They never stop pushing the liquids. All positive displacement pumps must have a protection device (relief valves) on the discharge end, and should never be operated with the discharge closed. There are several types of positive displacement pumps: Gear Lobe Vane Screw 21 07:34 22 RECIPROCATING PUMPS A positive displacement pump Piston reciprocates back and forth inside a cylinder. The liquid piston is driven by power piston. 07:34 Classed as: Single-acting or double-acting. Simplex or duplex. A simplex pump has only single pumping cylinder and a duplex pump has two. High or low pressure. A single acting pump pumps only on one side of the liquid piston; whereas a double acting pumps on both sides. The pump shown above is a double acting pump. When the power piston is larger than the liquid piston, the pump is high pressure. Vertical or Horizontal 23 RECIPROCATING PUMP 07:34 A reciprocating pump moves water or other liquid by a plunger or piston that reciprocates (travel back and forth) inside a cylinder. Reciprocating pumps are positive-displacement pumps; each stroke displaces a definite quantity of liquid, regardless of the resistance against which the pump is operating. 24 RECIPROCATING PUMP classified as follows: Direct-acting or indirectacting Simplex (single) or duplex (double) Single-acting or double-acting High-pressure or low-pressure Vertical or horizontal 07:34 Usually 25 RECIPROCATING PUMPS A full description of a reciprocating pump includes three numbers followed by it classification. For example, a pump is a Duplex, double acting, 8 6 12. 07:34 Two pumping cylinders, which pump on both sides of the cylinders. The power pistons are 8” in diameter. The liquid pistons are 6” in diameter, The pump has a 12 in stroke. Formulas for calculating the capacity and discharge pressure of a reciprocating pump is PLAN(power end) = PLAN(pump end) P = Inlet pressure on the power piston and the discharge pressure on the discharge end L = length of the pump stroke. A = the areas of the cylinders, power end, and pump end. N = number of strokes per min. 26 RECIPROCATING PUMPS can be determined with the formula: 07:34 Capacity Capacity= LAN / (321 in3 per gal) = GPM The liquid end piston area is used to determine the pump capacity Pump discharge pressure can be determined with this formula: P(Liquid)= P(power) × A(power)/ A(Liquid) 27 PUMP TERMS Pump capacity The capacity of a pump is the amount of liquid the pump can handle in a given period of time. It is usually expressed in GPM delivered at a specific pressure. What happens to the pump capacity as the viscosity of the fluid increases? Increase or decrease? 07:34 28 PUMP TERMS Total pump head Head is the vertical distance between the two liquid levels in a pumping system. Total pump head is the sum of the suction lift and the discharge head. The pump may be installed at, above, or below the surface of the source supply. When the pump is below the suction liquid level, it has a static suction pressure. When it is above, it has a static suction lift. 07:34 29 PUMP TERMS Total pump head The vertical distance from the centerline of the pump to the liquid level on the discharge is known as the static discharge head. Friction head- In addition to the head pressures, there is always a friction loss associated with the system. The energy required to overcome this loss manifests itself as thermal energy, which remains in the liquid. 07:34 30 PUMP TERMS 07:34 Velocity head The head pressure required to impart velocity to a fluid. 2 Formula Hv = V /2g Hv is the velocity head in feet Net Positive Suction Head (NPSH) It is the head necessary needed to overcome the friction and flow losses in a pump’s suction. The minimum suction head will be supplied by the pump manufacturer. If a pump is operated below the NPSH, cavitation can occur. 31 CAVITATION Cavitation is the formation and subsequent collapse of vapor-filled cavities or bubbles in the pumped liquid. Cavitation creates noise and vibration in a pump, and if it is allowed to continue it will cause pitting on the internal metal surfaces of the pump. 07:34 32 PUMP TERMS power required to drive a pump is a function of the pump capacity and the total head against which the pump operates. Measured in HP, how much horse power is necessary to deliver the required liquid against the pumping head. Bernoulli’s Theorem- A form of the general energy equation. 07:34 The Energy in = energy out There is not a direct correlation between in and out energy because of efficiency 33 Ejecter 07:34 34 07:34 35 07:34 THANK YOU 36