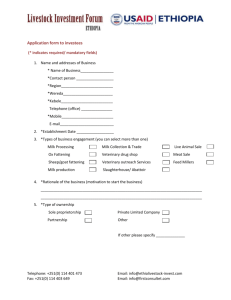

Solar steam pump - LIVES

advertisement

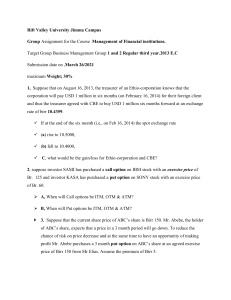

SUNFLOWER PUMP ILRI, 12th April 2012 The Sunflower Pump What is the Sunflower pump? • • • • • • • Solar thermal household water pump Designed for irrigation Allows dry season cultivation of cash crops Ground water depth range < 15m Suction pumping also possible Add-on – battery, mobile charge? Target cost 4500 – 6000 Birr Pump in Operation • See videos Design criteria • • • • • • Low capital cost Negligible running costs, High daily water yield Hard wearing Manual back-up Simple components to maximise local manufacturing and assembly • VLOM (like a bicycle) Key Benefits • Create income generating opportunities for poor small holder farmers • Improve food security during dry seasons (climate change adaptation) • Free children and women from the onerous task of lifting water • Provide an alternative to polluting, expensive fossil fuel pumps • Catalyse creation of small businesses in manufacturing, assembly, repairs, sales etc. • Provide other rural power requirements Team International • Sunflower.org (UK) – company dedicated to commercialisation of solar steam pump • Practica Foundation (Holland) – appropriate technology research and development NGO • IDE (Ethiopia & US) – NGO focused on ‘creating income generating opportunities for rural poor’ Local • Manufacturing Partners – to manufacturer, assemble, install , post-sales service. • Local Facilitating Partners – promotion, training, quality control, maintenance i.e. Technology Support Development timeline Funding secured Not funded • 1980s - 2009 experimentation and testing of early prototypes • 2009 – working prototype that satisfies all design criteria • 2010 – initial field testing in Ziway, Oromia • 2011 – design and testing of improved prototype in Netherlands; market and manufacturing study in Ethiopia • 2012 – further supply chain research, trial manufacturing and assembly of 10 – 20 units in Addis/Bahir Dar; extended field testing/pilot installations around Ethiopia. • 2013 – manufacturing blueprint; selection of local partners; volume production; development and training of support services, marketing and sales Funding • Liberty Foundation – 150, 000 Euros – R&D – Market study – Local manufacturing study – Ten improved prototypes in field • REEEP/IDE – 150, 000 Euros – Supply chain study – Financing mechanisms – Local v global production study – Design optimisation for mass production – Development of training materials Daily yield v. ground water depth (3 sqm collector, n = 1.2%, G = 900W/sqm.) Yield (litres) Cultivated Area (sqm.) 30000 3000 25000 2500 20000 2000 15000 1500 10000 1000 5000 500 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 SWL (m) Income potential Irrigated area Daily water (m2) (litres) Onions Onions seedlings 200 1000 100 Cabbages Peppers REVENUE Time to harvest Crop density Productivity Revenue per unit Revenue (ETB) 4 - 8 birr/kg 5,400.00 150 - 260 birr 3,600.00 30 birr/kuntal 1,040.00 6 birr/kg Total income 7,200.00 17,240.00 CROP TOTAL COSTS Seeds Fungicide Insecticide 4.5 months 45 1 kg/10 plants 500 45 days 1 merip/ 10sqm. 60 300 2 60 420 300 2100 Continual 3-5 months 2 crops/dry season 2-4 kuntal/2 weeks 4 5 kilos/plant Unit price (ETB) Description Unit Imported indian seeds Rediomil Gold Selecron tin kg 0.5ltr 150 250 290 12.00 1.00 1.00 1,800 250 290 complete 750 1.00 750 Distribution system Drum and hose Labour Transport to market plants/m2 No Total (ETB) n/a Donkey cart ETB 0 journey 5 30.00 150 Total costs 3,240 ANNUAL REVENUE = 14, 000 BIRR (if crop quality and market prices are optimal) Market potential Woreda HH %Irr <6m 6-12m 12-18m Total Rating Jebitenan 37,802 53.3% 8728 5923 5103 19754 54 Banja Shekudad 17,975 40.0% 3981 2318 1678 7977 51 Dangila 27,017 46.0% 6454 3669 2871 12994 51 Fagitalekuma 24,045 38.5% 4484 2565 2478 9527 49 Mecha 59,016 51.0% 13,549 9,128 7,072 29749 49 Fogera 45,820 54.0% 20,602 4,030 2,613 27245 49 S. Achefer 26,189 35.0% 4236 2800 2667 9703 47 This represents a total of almost 100, 000 households. Nation Development • • • • • • Growth and transformation plan Green economy Business and job creation Climate change resilience Green energy for Millennium Development Goals Ethiopian pump exports IMPROVED PUMP • Insert photo • Insert photo • Insert photo • Insert photo Next steps • • • • Trial local manufacturing of improved prototype Extended field testing/demonstration Identify facilitating partners Development of Technology Support Program o o o o o Promotion and dissemination Establishment of repair and maintenance network Training and production of training materials Certification/ Quality control Agreements with credit agencies o Low volume deployment in one/two Regions www.sunflowerpump.org