(Lin and Hwang, 2004) 3D Full-Tire Steady State Rolling

advertisement

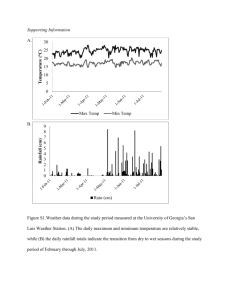

Prediction of Temperature Distribution of Steady State Rolling Tires E. Ledbury, L. Wang, D. Johnson, C. Bouvard, S.D. Felicelli Mississippi State University Introduction Diagram of an example of a coupled thermo-mechanical model including three modules Deformation Module • Use ABAQUS tire analysis capability • Hyperelastic material • Steady-state rolling analysis • Input: weight, speed, inflation pressure, road friction • Output: Strain – Stress Mechanical Analysis Sequence Dissipation Module The energy dissipated in the tire by viscoelastic effects can be obtained from the hysteresis of the material H U loss U total H Hysteresis (obtained from DMA testing) U total Total strain energy in tire (obtained from Mechanical Module) U loss Strain energy lost by dissipation Heat generation q U loss VL D ( H U total ) VL Vehicle speed D Tire diameter 2D Axi-symmetric Tire Model Tire (185/60 R15) Geometry and Meshing Material Properties (Lin and Hwang, 2004) Components Material Apex Apex Properties Hyperelastic Density (kg/m³) 1200 InnerLiner InnerLiner Bead Rebar Rubber, Ply Rubber Hyperelastic 1200 Elastic 6500 Hyperelastic 1200 SideWall SideWall Compound Hyperelastic 1200 Tread Tread Hyperelastic 1200 Poison's Ratio - - 0.3 - - Young's Modulus (Pa) Mooney-Rivlin Constants (MPa) - - 207×109 - - C10 = 118.9 C01= -71.8 D1 = 0.003 C10 = 118.9 C01= -71.8 D1 = 0.01 - C10 = 118.9 C01= -71.8 D1 = 0.03 C10 = 118.9 C01= -71.8 D1 = 0.01 C10 = 118.9 C01= -71.8 D1 = 0.04 Displacement Contour Displacement for half-tire static modeling (6 kN, 50 psi) Displacement vs. Loading Comparison between model prediction and experiments (Lin and Hwang, 2004) 3D Full-Tire Steady State Rolling Displacement Displacement for 3D full-tire steady state rolling modeling (6kN, 50 psi, 80 km/h) Strain Energy Density ESEDEN at the cross-section connecting to the road contact for 3D full tire steady state rolling modeling (6kN, 50 psi, 80 km/h) Temperature Distribution (50 psi, 60 km/h) Max Temp. in Tire Shoulder